XPS Surface Analysis: A Comprehensive Guide to IUPAC Protocols and Advanced Applications

This article provides a thorough overview of X-ray Photoelectron Spectroscopy (XPS) based on IUPAC protocols and current best practices.

XPS Surface Analysis: A Comprehensive Guide to IUPAC Protocols and Advanced Applications

Abstract

This article provides a thorough overview of X-ray Photoelectron Spectroscopy (XPS) based on IUPAC protocols and current best practices. Tailored for researchers, scientists, and drug development professionals, it covers the foundational principles of XPS as defined by IUPAC, methodological workflows for data acquisition and interpretation, strategies for troubleshooting common issues like charging and contamination, and guidelines for data validation and comparative analysis with other techniques. The content synthesizes information from authoritative sources, including IUPAC Technical Reports and recent scientific literature, to empower users in generating reliable, reproducible surface chemical data for advanced materials and biomedical research.

What is XPS? Understanding IUPAC Definitions and Core Principles

IUPAC Gold Book Definition of XPS and ESCA

Definition and Core Concepts

According to the IUPAC Gold Book, X-ray photoelectron spectroscopy (XPS) is defined as any technique in which the sample is bombarded with X-rays and photoelectrons produced by the sample are detected as a function of energy. The term Electron Spectroscopy for Chemical Analysis (ESCA) refers specifically to the use of this technique to identify elements, their concentrations, and their chemical state within the sample [1].

XPS is a surface-sensitive quantitative spectroscopic technique that measures the very topmost 50–60 atoms (5–10 nm) of any surface [2]. The technique is based on the photoelectric effect and enables the identification of elements present within a material (elemental composition) or covering its surface, as well as their chemical state, and the overall electronic structure [2].

The fundamental equation in XPS is the photoelectric effect equation:

[ E{\text{binding}} = E{\text{photon}} - (E_{\text{kinetic}} + \phi) ]

Where (E{\text{binding}}) is the binding energy of the electron measured relative to the sample Fermi level, (E{\text{photon}}) is the energy of the X-ray photons being used, (E_{\text{kinetic}}) is the kinetic energy of the electron as measured by the instrument, and (\phi) is the work function of the spectrometer [2].

Table 1: Core Terminology in XPS/ESCA

| Term | Definition | Significance |

|---|---|---|

| XPS | Technique detecting photoelectrons as function of energy during X-ray bombardment [1] | General analytical method for surface analysis |

| ESCA | Application of XPS specifically for elemental identification, concentration measurement, and chemical state analysis [1] | Emphasizes chemical information capability |

| Surface Sensitivity | Analysis of topmost 5-10 nm (50-60 atoms) of a material [2] | Critical for interface and thin film studies |

| Chemical Shift | Small binding energy changes (few eV) indicating different chemical states [2] | Reveals chemical bonding information |

Experimental Principles and Methodologies

Fundamental Physical Principles

XPS belongs to the family of photoemission spectroscopies in which electron population spectra are obtained by irradiating a material with a beam of X-rays [2]. When an X-ray photon of known energy strikes an atom, it can eject a core-level electron if the photon energy exceeds the electron's binding energy. The kinetic energy of this ejected photoelectron is measured by the spectrometer, allowing calculation of the original binding energy through the photoelectric equation [2].

The surface sensitivity of XPS arises from the short inelastic mean free path of electrons in solids, which limits the escape depth of photoelectrons without energy loss to typically less than 10 nm [2]. This makes XPS particularly valuable for studying surface reactions, contamination, functionalization, and thin films.

Technical Implementation

XPS requires high vacuum (residual gas pressure p ~ 10⁻⁶ Pa) or ultra-high vacuum (p < 10⁻⁷ Pa) conditions to allow the ejected photoelectrons to travel to the detector without colliding with gas molecules [2]. However, a current area of development is ambient-pressure XPS, which enables sample analysis at pressures of a few tens of millibar [2], as exemplified by the EnviroESCA system that allows analyses at pressures far above UHV [3].

The measured area in XPS depends on instrument design, with minimum analysis areas ranging from 10 to 200 micrometers for laboratory instruments, and down to 200 nm or below for imaging XPS instruments using synchrotron radiation [2].

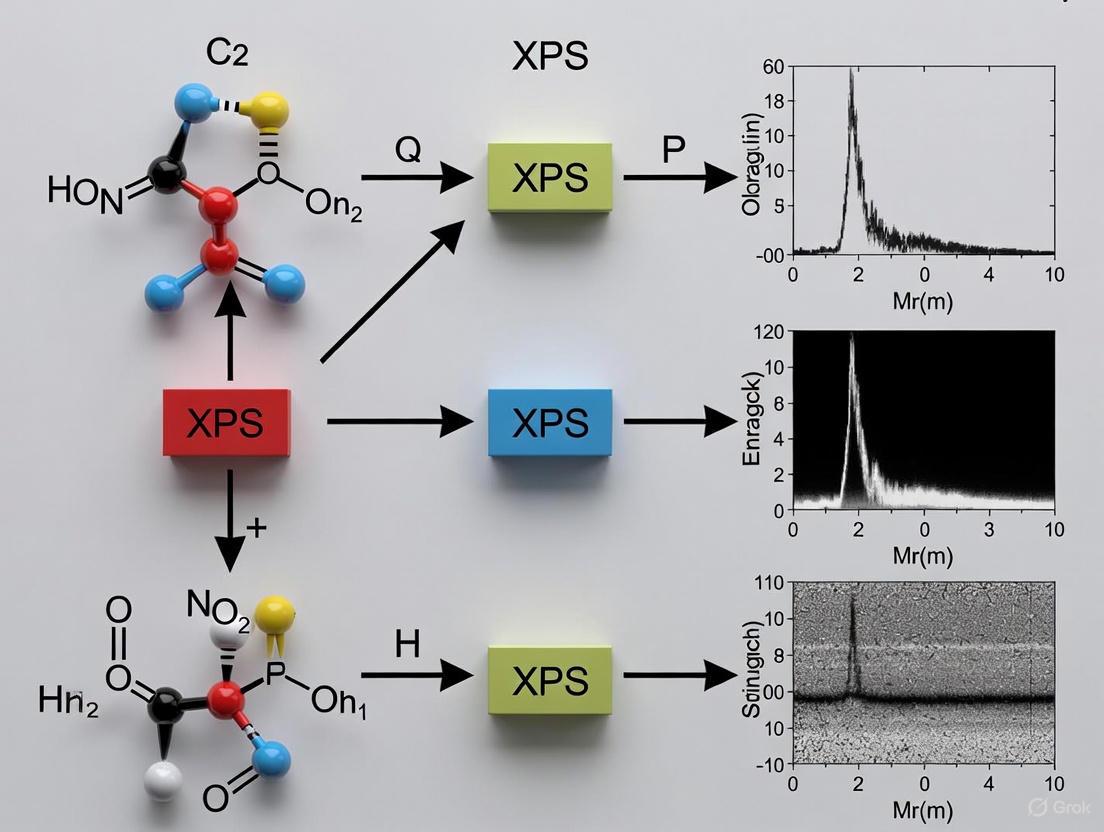

Figure 1: XPS Experimental Workflow from Sample to Analysis

Research Reagent Solutions and Essential Materials

Table 2: Essential Research Reagents and Materials for XPS Analysis

| Material/Reagent | Function/Purpose | Application Notes |

|---|---|---|

| Reference Materials (Au, Ag, Cu) | Energy scale calibration | High-purity foils for spectrometer calibration |

| Conductive Adhesive Tapes | Sample mounting | Provides electrical contact for charge compensation |

| Argon Gas Supply | Ion source for depth profiling | Sputtering for surface cleaning and depth profiling |

| Charge Neutralizers | Electron/flood gun source | Compensates charging on insulating samples |

| Cryogenic Cooling Stages | Sample temperature control | Prevents damage to sensitive materials |

| UHV-Compatible Materials | Sample holders and components | Minimizes outgassing in vacuum environment |

Analytical Capabilities and Performance Specifications

Elemental Detection and Quantification

XPS detects all elements except hydrogen and helium when using laboratory X-ray sources [2]. The detection limit is typically in the parts per thousand range, but parts per million (ppm) are achievable with long collection times and concentration at the top surface [2].

Quantitative accuracy in XPS depends on several parameters including signal-to-noise ratio, peak intensity, accuracy of relative sensitivity factors, correction for electron transmission function, surface volume homogeneity, and correction for energy dependence of electron mean free path [2]. Under optimal conditions, the quantitative accuracy of the atomic percent (at%) values calculated from the major XPS peaks is 90-95% for each peak [2].

Table 3: XPS Analytical Performance Characteristics

| Parameter | Typical Performance | Notes/Limitations |

|---|---|---|

| Detection Limits | 0.1-1.0 atomic % (1000 ppm) [2] | Can reach ppm range with long acquisition times [2] |

| Depth Resolution | 5-10 nm (topmost layers) [2] | Limited by electron escape depth |

| Lateral Resolution | 10-200 μm (standard); <200 nm (imaging) [2] | Dependent on instrument design |

| Quantitative Accuracy | 90-95% for major peaks; 60-80% for minor peaks [2] | Relative accuracy better than absolute |

| Analysis Time | 1-20 min (survey); 1-15 min (high-res); 1-4 hr (depth profiles) [2] | Dependent on signal quality requirements |

Chemical State Analysis

One of the most powerful capabilities of XPS is its ability to provide chemical state information through small shifts in electron binding energies [2] [4]. These chemical shifts occur because the binding energy of a core electron depends on the chemical environment of the atom. For example, the binding energy of carbon 1s electrons differs measurably between hydrocarbons, alcohols, carboxylic acids, and other functional groups.

This chemical state analysis capability makes XPS particularly valuable for studying glass surfaces [4], catalysts [3], polymers, and various other materials where surface composition differs from the bulk or where surface reactions are of interest.

Application Protocols

Standard Analysis Protocol for Solid Materials

Sample Preparation: Cut sample to appropriate size (typically <1 cm × 1 cm). For non-conducting samples, use minimal amounts of conductive adhesive. Avoid surface contamination by handling with gloves and tweezers.

Sample Loading: Transfer sample to instrument introduction chamber quickly to minimize air exposure. For air-sensitive samples, use transfer vessels that maintain inert atmosphere or controlled environment.

Pump Down: Begin evacuation process, typically starting with roughing pump followed by high-vacuum pumps until UHV conditions (<10⁻⁷ Pa) are achieved in analysis chamber.

Instrument Calibration: Verify energy scale calibration using reference materials (typically gold, silver, or copper foils) measuring known peaks such as Au 4f₇/₂ at 84.0 eV.

Preliminary Survey Scan: Collect wide energy range survey spectrum (e.g., 0-1100 eV binding energy) to identify all elements present. Use pass energy of 80-100 eV for optimal sensitivity.

High-Resolution Regional Scans: Acquire detailed spectra of each identified element using higher energy resolution (pass energy of 20-50 eV). Ensure sufficient counting statistics by appropriate dwell times and multiple scans if necessary.

Charge Correction: For insulating samples, apply charge correction referencing to adventitious carbon (C 1s typically set to 284.8 eV) or use internal standard.

Data Analysis: Identify elements present, determine chemical states from binding energy positions and peak shapes, and calculate atomic concentrations using appropriate sensitivity factors.

Specialized Methodologies

Angle-Resolved XPS (ARXPS): Varying the take-off angle between sample surface and analyzer to achieve different depth sensitivities. This non-destructive method provides depth distribution information within the top 5-10 nm.

Depth Profiling: Combining XPS measurement with ion beam sputtering (typically Ar⁺ ions) to remove surface layers gradually, enabling composition analysis as a function of depth.

Environmental XPS/EnviroESCA: Performing analysis under near-ambient pressure conditions (up to several tens of mbar) using specialized instruments [3]. This allows investigation of samples in their native hydrated states, catalysts under working conditions, and liquid-solid interfaces.

Cryogenic Techniques: Freezing hydrated samples in ultrapure environment and allowing multilayers of ice to sublime away prior to analysis, enabling study of hydrogels and biological samples [2].

Data Interpretation and Reporting Standards

Spectral Interpretation Guidelines

Proper interpretation of XPS data requires systematic approach:

Elemental Identification: Identify all elements present from the survey spectrum by matching peak positions with known electron binding energies.

Chemical State Analysis: Examine high-resolution spectra for chemical shifts that indicate different chemical environments. Compare with databases of known compounds.

Peak Fitting: Deconvolve complex peaks into individual components representing different chemical states when necessary. Use appropriate background subtraction and physically realistic peak shapes (typically Gaussian-Lorentzian mixes).

Quantification: Calculate atomic concentrations using peak areas corrected with relative sensitivity factors (RSFs) that account for elemental cross-sections and instrument transmission function.

Minimum Reporting Standards

For research publications, comprehensive reporting should include [5]:

- Instrument Parameters: Manufacturer, model, X-ray source (anode material, monochromatic or non-monochromatic), analyzer pass energy, step size.

- Calibration Details: Energy scale calibration method and reference values.

- Charge Correction: Method used for charge compensation and reference peak positions.

- Data Processing: Background subtraction method, peak fitting parameters (peak shape, FWHM constraints).

- Sensitivity Factors: Source of relative sensitivity factors used for quantification.

- Sample Preparation: Detailed description of sample handling, mounting, and any pre-treatment.

The widespread use of XPS has led to increased recognition of the need for standardized methodologies and reporting to ensure reproducibility and reliability of results [5]. Proper application of XPS protocols enables this powerful technique to provide invaluable insights into surface composition and chemistry across diverse fields from materials science to biotechnology.

The photoelectric effect is the fundamental physical process that enables X-ray Photoelectron Spectroscopy (XPS), a surface-sensitive analytical technique. This quantum phenomenon, for which Albert Einstein received the Nobel Prize, describes the emission of electrons from a material when it is illuminated by light of sufficient energy [5] [6]. In modern XPS instruments, this principle is applied by directing mono-energetic X-rays onto a sample surface, causing the ejection of core-level photoelectrons [6]. The kinetic energy of these emitted electrons is measured, and since their binding energy is a unique signature of the element and its chemical environment, a detailed composition of the top 1 to 10 nanometers of the surface can be determined [7] [8]. This exceptional surface sensitivity makes XPS indispensable across numerous fields, including materials science, catalysis, electronics, and biomedical engineering, providing invaluable quantitative and chemical state information from the material surface [5] [6].

Core Physical Principles from Theory to Measurement

The operational principle of XPS rests entirely on the photoelectric effect and the conservation of energy. When an X-ray photon of energy (h\nu) is absorbed by an atom, it can eject a core electron. The relationship between the kinetic energy (KE) of the emitted photoelectron and its original binding energy (BE) within the atom is given by the core photoelectric equation:

[ KE = h\nu - BE - \phi ]

where (h\nu) is the energy of the incident X-ray photon, and (\phi) is the work function of the spectrometer [6] [9]. By using a known, mono-energetic X-ray source (such as Al Kα at 1486.6 eV), and measuring the kinetic energy of the ejected electrons with an electron energy analyzer, the binding energy can be directly calculated [6]. This binding energy is a unique identifier for each element (except hydrogen and helium) and is sensitive to the chemical bonding of the atom, experiencing small shifts (chemical shifts) that provide information about its chemical state [5] [8].

The analysis depth of XPS is typically less than 10 nm because the emitted photoelectrons have a short inelastic mean free path in solids, meaning they can only travel a short distance without losing energy [6] [8]. This makes XPS an inherently surface-sensitive technique. The following diagram illustrates the core physical process and the energy relationships involved.

Diagram 1: The photoelectric process and energy balance in XPS.

Information Content in the Photoelectron Spectrum

The fundamental physics of the photoelectric effect translates directly into the rich information content of an XPS spectrum:

- Elemental Identification: Each element produces a characteristic set of photoelectron peaks at specific binding energies (e.g., Au 4f, O 1s, C 1s), allowing for qualitative analysis [5].

- Chemical State Information: Changes in the chemical environment of an atom cause small shifts (0.1 - 4 eV) in the binding energy of its photoelectrons. For example, the carbon 1s peak has different binding energies depending on whether the carbon is in a hydrocarbon, alcohol, or carbonyl group [5] [8].

- Quantitative Analysis: The intensity of a photoelectron peak (measured by the area under the peak) is proportional to the concentration of that element within the analysis volume. With appropriate sensitivity factors, these intensities can be used for quantitative composition analysis [5].

Table 1: Key Photoelectron Lines and Their Information Content in XPS Analysis

| Element | Core Level | Binding Energy Range (eV) | Chemical Shift Example | Information Obtained |

|---|---|---|---|---|

| Carbon | C 1s | 284 - 292 | C-C/C-H vs C=O | Distinguishes hydrocarbon contamination from carbonyl groups in polymers or adsorbed species [8]. |

| Oxygen | O 1s | 530 - 533 | Metal-O vs O-C | Differentiates between oxide layers (e.g., SiO₂) and organic oxygen (e.g., in adhesives) [8]. |

| Nitrogen | N 1s | 398 - 402 | -NH₂ vs -NO₂ | Identifies different functional groups in biological films or explosives residues. |

| Silicon | Si 2p | 99 - 104 | Si⁰ vs SiO₂ | Differentiates elemental silicon (wafer) from silicon dioxide (silica) [8]. |

Experimental Protocol: From Sample to Spectrum

Adhering to a standardized protocol is critical for obtaining reliable and reproducible XPS data, a point heavily emphasized in modern guides to combat a "significant reproducibility crisis" in science [5]. The following section outlines a detailed experimental methodology.

Sample Preparation and Handling Protocol

Objective: To introduce the sample into the XPS instrument without altering its surface chemistry or introducing contaminants.

Materials:

- XPS Sample Holder: Typically a stainless steel stub or plate.

- Conductive Adhesive Tape: Such as double-sided carbon tape, for mounting powdered or non-conducting samples to ensure electrical and thermal contact.

- Metal Foils: High-purity indium or gold foil can be used as substrates for delicate samples.

- Sample Inert Transfer Container: A vessel filled with an inert gas (e.g., Ar or N₂) for transporting air-sensitive samples to the load-lock.

Procedure:

- Initial Inspection: Visually inspect the sample for macroscopic features, blemishes, or particles of interest. If necessary, use an optical microscope or SEM integrated with the XPS system [7].

- Mounting:

- For solid, conductive samples, secure the sample firmly to the holder using screws or clamps.

- For powders or non-conducting samples, apply a small amount of powder to a conductive adhesive tape mounted on the holder. Gently tap off excess powder to create a thin, uniform layer.

- Contamination Mitigation: Handle samples only with clean, powder-free gloves and tweezers to prevent contamination from skin oils or particulates. The prevalence of adventitious carbon from airborne hydrocarbons is a major concern and is often used for charge referencing, though its arbitrary application has been criticized [9].

- Transfer: Place the mounted sample into the XPS introduction load-lock as quickly as possible to minimize additional air exposure. Evacuate the load-lock according to the instrument's standard operating procedure before transferring into the ultra-high vacuum (UHV) analysis chamber.

Instrument Setup and Data Acquisition Protocol

Objective: To collect XPS spectra with sufficient quality and appropriate parameters to answer the analytical question.

Materials:

- XPS Instrument: Operating under ultra-high vacuum (< 1 × 10⁻⁸ mbar).

- Reference Sample: A clean, standard material such as gold or silver foil for verifying instrument performance and energy scale calibration [5].

Procedure:

- Instrument Calibration Check:

- Insert the reference sample and acquire a survey spectrum and a high-resolution spectrum of a known peak (e.g., Au 4f₇/₂).

- Verify that the measured binding energy matches the known value (84.0 eV for Au 4f₇/₂) within the manufacturer's specification (typically ±0.1 eV).

- Data Collection Plan: Define the analytical objective and plan the measurements accordingly [5]:

- Survey Spectrum: Acquire over a wide binding energy range (e.g., 0-1100 eV) to identify all elements present.

- High-Resolution Regional Spectra: Acquire over narrow energy ranges for elements of interest to determine chemical states and for quantification.

- Specialized Modes: Determine if angle-resolved XPS (ARXPS) for depth profiling, XPS imaging/mapping, or ion sputtering for depth profiling is required [7].

- Spectrum Acquisition:

- For Survey Spectra: Use a pass energy of 80-160 eV for high sensitivity and short acquisition times.

- For High-Resolution Spectra: Use a lower pass energy (20-40 eV) for higher energy resolution.

- Charge Compensation: For electrically insulating samples, activate the low-energy electron flood gun and/or argon ion source to neutralize positive surface charge. Adjust parameters to achieve a stable and narrow peak shape [7].

- Acquisition Parameters: Set the step size (e.g., 0.1 eV for high-resolution, 1.0 eV for survey) and dwell time per step. Collect sufficient scans to ensure good counting statistics (signal-to-noise ratio).

The logical workflow for an XPS analysis, from planning to reporting, is summarized in the following diagram.

Diagram 2: XPS analysis workflow from question to report.

Data Processing, Interpretation, and Reporting Protocol

Objective: To extract meaningful elemental and chemical state information from the raw spectral data and report it comprehensively.

Procedure:

- Charge Referencing (Critical Step):

- For samples with an adventitious carbon layer, the most common method is to set the C 1s peak maximum to 284.8 eV [9]. However, be aware that this method can be "highly arbitrary" and lead to incorrect interpretations if applied indiscriminately [9].

- For conductive samples, reference to a known intrinsic peak (e.g., metal peak from the substrate).

- Background Subtraction: Apply a suitable background (e.g., Shirley or Tougaard) to remove the contribution of inelastically scattered electrons.

- Peak Fitting:

- Identify all possible chemical components for a given element based on the sample history and chemistry.

- Use appropriate peak shapes (mixed Gaussian-Lorentzian lineshapes) and constraints during fitting.

- Ensure the full width at half maximum (FWHM) of components from the same elemental spectrum are consistent.

- Quantification: Calculate atomic concentrations (%) using the peak areas and relative sensitivity factors (RSFs) provided by the instrument manufacturer.

- Reporting: A complete report must include information necessary for others to reproduce the results [5]:

- Sample details: History, preparation, and any treatments.

- Instrument details: Manufacturer, model, X-ray source, analyzer pass energy, and step size.

- Calibration status: Reference sample and measured binding energy.

- Data analysis details: Charge correction method, background type, and peak fitting parameters.

Advanced Applications and Complementary Techniques

The basic principles of the photoelectric effect are leveraged in several advanced XPS modes and complementary surface analysis techniques to extract deeper information.

Advanced XPS Techniques

- XPS Depth Profiling: Uses an ion beam (monatomic or gas cluster) to sputter away the surface layer by layer, with XPS analysis performed after each sputtering cycle. This reveals the composition as a function of depth from the surface, crucial for studying interfaces, thin films, and corrosion [7].

- Angle-Resolved XPS (ARXPS): By collecting photoelectrons at varying emission angles (relative to the surface normal), the effective analysis depth is changed. This non-destructive method provides information on the thickness and composition of ultra-thin films (1-5 nm) [7].

- XPS Imaging (or Mapping): Creates a spatial map of the distribution of specific elements or chemical states across the sample surface by scanning a micro-focused X-ray beam and recording spectra at each pixel [7] [6].

Complementary Surface Analysis Techniques

No single technique provides a complete picture. The following table outlines key techniques that complement the information obtained from XPS.

Table 2: Complementary Surface Analysis Techniques

| Technique | Acronym | Primary Probe | Key Information | How it Complements XPS |

|---|---|---|---|---|

| Auger Electron Spectroscopy | AES | Focused Electron Beam | Elemental composition, some chemical state, high lateral resolution (~10 nm) | Provides superior spatial resolution for micro-analysis; Auger features can also be observed in XPS spectra [7]. |

| Ultraviolet Photoelectron Spectroscopy | UPS | UV Photons | Valence electronic structure, work function, occupied states | Probes the lower binding energy valence levels involved in bonding, complementing core-level XPS data [7]. |

| Ion Scattering Spectroscopy | ISS | Noble Gas Ions | Elemental composition of the outermost atomic layer | More surface-sensitive than XPS, ideal for studying surface segregation and monolayer growth [7]. |

| Reflected Electron Energy Loss Spectroscopy | REELS | Electrons | Electronic structure, band gaps, unoccupied states, can detect H | Complements UPS for electronic properties; can detect hydrogen, which is not possible with laboratory XPS [7]. |

| Raman Spectroscopy | - | Laser (IR-UV) | Molecular bonding, vibrational modes, material structure | Provides bulkier information but is very sensitive to structural changes (e.g., in polymers, graphene) [7]. |

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key materials and reagents essential for preparing and analyzing samples via XPS.

Table 3: Essential Materials for XPS Analysis

| Item Name | Function/Application | Critical Specifications |

|---|---|---|

| Conductive Adhesive Tapes | Mounting powdered, fragile, or non-conducting samples to the holder. | High-purity carbon or copper tape; low outgassing in UHV. |

| Standard Reference Foils | Verifying instrument energy scale calibration and resolution. | High-purity (99.99%+) gold, silver, or copper. |

| Inert Gas Sample Transfer Kit | Transporting air-sensitive samples (e.g., catalysts, batteries) without oxidation. | Sealed container with glove bag and argon gas supply. |

| Sputter Depth Profiling Ion Source | Cleaning surfaces and performing depth profiling to reveal in-depth composition. | Gas cluster ion source for organic materials; monatomic source for inorganics [7]. |

| Charge Neutralization Source | Compensating for positive charge buildup on insulating samples. | Low-energy electron flood gun combined with low-energy argon ions [7]. |

X-ray Photoelectron Spectroscopy (XPS), also referred to as Electron Spectroscopy for Chemical Analysis (ESCA), is a highly surface-sensitive quantitative spectroscopic technique that measures the very topmost 5–10 nm of any surface [2]. This analytical method is invaluable for determining the empirical formula of materials and is uniquely capable of providing chemical state information from the top few molecular layers of a sample, a region critical to understanding material performance in applications ranging from catalysis to medical implants [10] [8]. Operating on the principle of the photoelectric effect, XPS enables researchers to identify not only what elements are present on a surface but also what other elements they are bonded to, providing a comprehensive picture of surface chemistry that is essential for advanced materials research and development [2] [11]. The following application note details the specific measurement capabilities of XPS, supported by standardized protocols and illustrative data, framed within the context of IUPAC-referenced surface analysis methodologies.

Core Measurement Capabilities of XPS

XPS provides three fundamental types of data that collectively offer a complete characterization of a material's surface chemistry, each critical for different aspects of materials science and engineering.

Elemental Composition

XPS quantitatively measures the elemental composition of the top 1–10 nm of a material [10] [2]. With the exception of hydrogen and helium, XPS can detect all elements in the periodic table, with detection limits typically ranging from 0.1 to 1.0 atomic percent (approximately 1000 to 100 ppm) [2] [11]. The quantitative process involves irradiating a solid surface with a beam of X-rays while simultaneously measuring the kinetic energy of electrons emitted from the topmost material layers [10]. Each element produces a set of characteristic XPS peaks corresponding to the electron configuration within its atoms (e.g., 1s, 2s, 2p, 3s, etc.) [2]. The number of detected electrons in each peak is directly related to the amount of the element within the XPS sampling volume, enabling precise quantification [2]. Under optimal conditions, the quantitative accuracy for major peaks reaches 90–95% of the true atomic percent value [2].

Table 1: XPS Elemental Detection Capabilities

| Aspect | Specification | Technical Notes |

|---|---|---|

| Analysis Depth | 5–10 nm [2] [6] | Information is collected from the top few nanometers where electrons can escape without significant energy loss [10] |

| Detectable Elements | All elements except hydrogen and helium [2] [11] | Detection of lithium, beryllium, and boron is possible, unlike with some other techniques [12] |

| Detection Limits | 0.1–1.0 atomic % (parts per thousand range) [2] [11] | Parts per million (ppm) achievable with long collection times and surface concentration [2] |

| Quantitative Accuracy | 90–95% for major peaks [2] | Accuracy for weaker signals (10-20% of strongest peak) is 60-80% of true value [2] |

| Lateral Resolution | ≥ 7.5 µm [6] | Smallest analytical area is approximately 10-30 µm [2] [11] |

Chemical State Information

One of the most powerful features of XPS is its ability to determine the chemical state of elements, effectively revealing what other elements they are bonded to [2] [11]. This capability arises from the "chemical shift" phenomenon, where the binding energy of a photoelectron peak changes slightly depending on the chemical environment of the atom [11]. These energy shifts occur when strong chemical bonds are formed between atoms, providing insights into oxidation states, chemical functional groups, and compound identification [8]. For example, XPS can readily distinguish between sulfate and sulfide forms of sulfur, differentiate between elemental silicon, silicon dioxide (silica), and silicon in a polymer, and identify various oxidation states of transition metals [11] [8]. This information is vital for understanding a material's bonding capabilities, corrosion behavior, catalytic activity, and suitability for different applications [8].

Electronic State

XPS measures the electronic state of elements within a material, revealing information about the overall electronic structure and density of electronic states [2]. The binding energy measured in XPS is referenced to the Fermi level of the sample, providing direct insight into the electronic environment of the atom [2]. This electronic state information can be crucial for understanding electrical contact properties, semiconductor behavior, catalyst mechanisms, and other electronic phenomena that govern material performance [12] [6]. The technique is particularly valuable for investigating how surface treatments, contamination, or processing conditions alter the electronic structure of materials, which in turn affects their performance in practical applications.

Experimental Protocols

The following section outlines standardized protocols for conducting XPS analysis, ensuring reliable and reproducible results that align with rigorous surface analysis standards.

Standardized Analytical Procedure

Diagram 1: XPS Analysis Workflow

A properly executed XPS analysis follows a systematic workflow to ensure data quality and interpretability:

Sample Preparation: Samples should be sized appropriately for the instrument's vacuum chamber and sample holder. Surface cleaning may be required to remove adventitious carbon or other contaminants that could interfere with analysis, unless the "as-received" surface state is the subject of study [2].

Ultra-High Vacuum Establishment: The sample must be introduced into an ultra-high vacuum (UHV) chamber with a residual gas pressure of approximately p < 10⁻⁷ Pa to minimize scattering of photoelectrons by gas molecules and prevent surface contamination [2].

Survey Scan Acquisition: A broad energy range scan (typically 0-1400 eV binding energy) is performed to identify all elements present on the surface, except hydrogen and helium. This scan uses high sensitivity settings and typically requires 1-20 minutes [2] [11].

High-Resolution Regional Scans: Narrow energy ranges encompassing the characteristic peaks of detected elements are scanned under high energy resolution conditions to obtain detailed chemical state information. Acquisition typically requires 1-15 minutes per region of interest [2] [11].

Charge Compensation (if needed): For electrically insulating samples, charge compensation neutralizes surface charge accumulation by replenishing electrons from an external source, stabilizing and controlling the charging to within a few electron volts of the neutral state [10].

Data Processing and Quantification: Elemental concentrations are calculated by correcting peak intensities with relative sensitivity factors (RSF) and normalizing over all detected elements. Chemical state identification is performed by analyzing binding energy shifts and peak shapes [2] [11].

Advanced Methodological Extensions

Beyond standard analysis, several specialized XPS techniques provide additional dimensional information:

Depth Profiling: A destructive technique that combines alternating cycles of ion beam sputtering (to remove material) and XPS data collection to construct a composition profile as a function of depth. This is essential for analyzing thin film structures, interfacial chemistry, and corrosion layers [10] [11]. Depth resolution typically ranges from 20–200 Å [11].

Angle-Resolved XPS (ARXPS): A non-destructive method that varies the emission angle at which electrons are collected, enabling analysis from different depths. ARXPS provides information about the thickness and composition of ultra-thin films (1-10 nm) without ion sputtering [10].

XPS Imaging / Mapping: Creates spatial images showing the distribution of specific elements or chemical states across a sample surface. This can be achieved through serial acquisition (mapping) or parallel acquisition (parallel imaging), with modern instruments achieving spatial resolution below 10 µm [10] [6].

Research Reagent Solutions and Materials

The following table details essential components and materials utilized in XPS analysis, forming the fundamental toolkit for researchers conducting surface characterization studies.

Table 2: Essential Research Reagents and Materials for XPS Analysis

| Item | Function/Application | Technical Specifications |

|---|---|---|

| Monochromatic X-ray Source | Excites photoelectrons from the sample surface; monochromatization improves energy resolution and reduces radiation damage [2] | Typically Al Kα (1486.7 eV) or Mg Kα (1253.7 eV); FWHM of 0.43 eV and 0.36 eV respectively [2] |

| Electron Energy Analyzer | Measures the kinetic energy of emitted photoelectrons with high precision | Hemispherical analyzer typically used for high energy resolution measurements [2] |

| Charge Neutralization System | Compensates for surface charging on insulating samples to enable accurate analysis [10] | Low-energy electron flood gun combined with argon ions; essential for analyzing ceramics, polymers, and glasses [10] |

| Dual-Mode Ion Source | Enables depth profiling by sputtering material from the surface; cluster ion sources allow analysis of organic and fragile materials [10] | Monatomic ions (e.g., Ar⁺) for inorganic materials; gas cluster ions (e.g., Arₙ⁺) for organic and polymeric materials [10] |

| Ultra-High Vacuum System | Maintains necessary environment for photoelectron detection without interference | Pressure < 10⁻⁷ Pa; minimizes surface contamination and scattering of photoelectrons [2] |

Comparative Analytical Techniques

XPS provides distinct advantages and limitations compared to other elemental analysis techniques, making it specifically suited for surface-specific analysis rather than bulk characterization.

Table 3: Comparison of Elemental Composition Analysis Techniques

| Technique | Analysis Depth | Elements Detected | Detection Limits | Chemical State Info | Key Strengths |

|---|---|---|---|---|---|

| XPS | 5–10 nm [12] | All except H and He [11] | 0.1–1 at% [11] | Yes [11] | Excellent surface sensitivity, quantitative, chemical state identification [11] |

| EDS/EDX | 500–3000 nm [12] | Na and heavier [12] | ~0.1–1 at% [12] | Limited | Rapid analysis, good for bulk composition of metals/alloys [12] |

| XRF | ~1500 nm [12] | C, N, O, F, Na and heavier [12] | Low ppm range [12] | Limited | Excellent for bulk analysis of solids and liquids, minimal sample prep [12] |

| LIBS | 5–7 µm [12] | All elements including H and He [12] | Varies by element | Limited | Can analyze all elements, portable systems available [12] |

Applications in Research and Development

The unique capability of XPS to provide quantitative elemental and chemical state information from the outermost surface layers makes it invaluable across numerous research domains:

Contamination Analysis and Failure Analysis: XPS effectively determines quantitative amounts of contamination on surfaces, identifying stains, discolorations, and residues that can cause adhesive bonding problems, thin film delamination, or initiate corrosion [11] [12] [8]. For instance, measuring the carbon-to-metal ratio on cleaned surfaces can objectively evaluate cleaning process efficacy [8].

Polymer Surface Characterization: XPS examines polymer functionality before and after processing to identify and quantify surface changes, including oxidation, functional group introduction, or contamination [11]. This is crucial for understanding adhesion properties, biocompatibility, and surface treatment effectiveness.

Thin Film and Interface Analysis: Through depth profiling, XPS characterizes thin film composition, layer structures, and interfacial chemistry for both conducting and non-conducting materials [11]. Applications include measuring oxide thickness on semiconductors, analyzing multilayer coatings, and understanding diffusion processes at interfaces [11] [6].

Biomaterials and Medical Research: XPS analyzes the surface composition of medical implants, bio-materials, teeth, and bones, providing critical information about surface chemistry that directly interacts with biological systems [2]. This is essential for understanding biocompatibility, biofouling, and material-tissue interactions.

Catalysis and Energy Materials: XPS identifies oxidation states and chemical environments in catalysts, electrodes, photovoltaic materials, and energy storage devices, enabling researchers to correlate surface chemistry with performance metrics [12] [6].

The protocols and applications detailed herein demonstrate that XPS provides unparalleled insights into surface composition and chemistry, making it an indispensable technique for advancing research in materials science, pharmaceuticals, electronics, and numerous other fields where surface properties dictate performance.

X-ray Photoelectron Spectroscopy (XPS) is a highly surface-sensitive, quantitative spectroscopic technique that measures the very topmost 50–60 atoms, corresponding to approximately 5–10 nm of any surface [2]. This exceptional surface sensitivity arises from the fundamental physics of the photoemission process and the short distance that electrons can travel through a solid without losing energy. Only electrons generated very near the surface can escape without losing too much energy for detection, which means that XPS data is collected predominantly from the top few nanometers of the material [10]. It is this precise surface selectivity, combined with quantitative chemical state identification, that makes XPS invaluable across a vast array of application areas including materials science, electronics, pharmaceuticals, and surface engineering.

The technique is based on the photoelectric effect, where X-ray irradiation of a material causes the ejection of core electrons from atoms residing at the surface [2]. The kinetic energy of these emitted photoelectrons is measured by the spectrometer, and their binding energy is calculated using the fundamental photoelectric equation:

Ebinding = Ephoton - (E_kinetic + ϕ)

where Ebinding is the binding energy of the electron, Ephoton is the energy of the X-ray photons, E_kinetic is the kinetic energy of the electron as measured by the instrument, and ϕ is the work function of the spectrometer [2]. The resulting spectrum provides a characteristic fingerprint that reveals not only the elemental composition but also the chemical state of the elements within the sampling volume.

Fundamental Principles of Surface Sensitivity

The Electron Escape Depth

The extreme surface sensitivity of XPS stems from the inelastic mean free path (IMFP) of electrons in solids, which is the average distance an electron can travel between inelastic collisions. Photoelectrons originating from depths greater than approximately 10 nm undergo energy-loss processes through multiple scattering events, which prevents them from escaping the surface with their original characteristic energy. Consequently, the detected signal in XPS comes predominantly from the top few nanometers, with the signal intensity decreasing exponentially with increasing depth [2].

The sampling depth varies with the kinetic energy of the ejected photoelectrons, but for conventional XPS using Al Kα radiation (1486.7 eV), the information depth is typically limited to the top 1-10 nm [10] [2]. This makes XPS particularly powerful for investigating surface phenomena that differ substantially from the bulk composition, such as contamination layers, surface oxidation, functionalization, and thin film coatings.

Chemical State Information and Chemical Shifts

A key advantage of XPS beyond elemental identification is its ability to provide chemical state information through precisely measured binding energies. In 1958, Siegbahn's group demonstrated that copper (I) oxide could be distinguished from copper (II) oxide by XPS, establishing the foundation for chemical state analysis [13]. The "chemical shift" refers to the change in binding energy when an atom is in different chemical environments or oxidation states. This shift occurs due to alterations in the electrostatic screening of core electrons when valence electrons are attracted or repulsed in the emitting atom [13].

For example, XPS can differentiate between various chemical environments of silicon, such as elemental silicon (as in a wafer), silicon dioxide (silica), or silicon bonded to organic groups (as in a polymer) [8]. This chemical state information is vital for understanding material bonding capabilities and suitability for different applications, particularly in drug development where surface functionalization critically influences performance.

Table 1: Key Characteristics of XPS Surface Sensitivity

| Parameter | Specification | Technical Basis |

|---|---|---|

| Analysis Depth | 1-10 nm | Limited by electron inelastic mean free path [10] [2] |

| Sampled Volume | Top 50-60 atomic layers | Corresponds to escape depth of photoelectrons [2] |

| Detection Limits | 0.1-1.0 atomic % (1000-100 ppm) | Varies with element cross-section and background; can reach ppm with long acquisitions [2] |

| Spatial Resolution | ≥3 μm with modern imaging systems | Dependent on instrument design and X-ray source [13] |

| Quantitative Accuracy | 90-95% for major peaks; 60-80% for minor peaks | Depends on signal-to-noise, sensitivity factors, and homogeneity [2] |

Experimental Protocols for Surface Analysis

Standard Operating Procedure for Surface Composition Analysis

Objective: To determine the elemental composition and chemical states of the top 1-10 nm of a material surface.

Materials and Equipment:

- XPS instrument with Al Kα or Mg Kα X-ray source

- Ultra-high vacuum chamber (pressure < 10⁻⁷ Pa)

- Sample holder appropriate for material type

- Charge compensation system (for insulating samples)

- Standard reference materials for energy calibration (e.g., Au, Ag, Cu)

Procedure:

- Sample Preparation:

- Cut sample to appropriate size for introduction into vacuum chamber.

- For powders, mount on double-sided adhesive tape or press into indium foil.

- Avoid excessive handling to prevent surface contamination.

- If possible, use in-situ cleaning methods (Ar⁺ sputtering) for reference surfaces.

Instrument Setup:

- Establish ultra-high vacuum (< 10⁻⁷ Pa) before analysis.

- Select X-ray source: Al Kα (1486.7 eV) or Mg Kα (1253.7 eV).

- For insulating samples, activate charge compensation system with low-energy electrons.

- Set analyzer pass energy to 20-50 eV for survey scans, 10-20 eV for high-resolution scans.

Data Acquisition:

- Collect survey spectrum (0-1000 eV or 0-1400 eV binding energy) to identify all detectable elements.

- Acquire high-resolution spectra for each identified element with appropriate energy range.

- Use step size of 0.1-0.5 eV for high-resolution scans.

- Accumulate sufficient scans to achieve acceptable signal-to-noise ratio (typically 5-20 minutes per high-resolution region).

Data Analysis:

- Calibrate spectrum using adventitious carbon (C 1s at 284.8 eV) or known reference peak.

- Identify elements present from characteristic binding energies.

- Perform nonlinear background subtraction (Shirley or Tougaard background).

- Fit high-resolution peaks with appropriate constraints (fixed spin-orbit splitting, area ratios).

- Calculate atomic concentrations using peak areas and relative sensitivity factors.

Reporting:

- Report all instrument parameters (X-ray source, power, analyzer settings).

- Include sample preparation methods and handling conditions.

- Present both survey and high-resolution spectra with fitted components.

- Tabulate atomic concentrations with estimated uncertainties.

Protocol for Angle-Resolved XPS (ARXPS) for Depth Profiling

Objective: To determine the depth distribution of chemical species in the top 1-10 nm without destructive sputtering.

Principles: ARXPS varies the emission angle at which electrons are collected, thereby changing the effective analysis depth. At grazing angles (high take-off angles), the signal becomes more surface-sensitive [10] [7].

Procedure:

- Mount sample on a stage capable of precise angular rotation.

- Acquire high-resolution spectra at multiple emission angles (typically 0° to 60° relative to surface normal).

- Ensure constant analysis area during angular rotation.

- Analyze angular dependence of elemental peaks to determine depth distribution.

- Use appropriate mathematical models (e.g., three-layer model) to calculate layer thicknesses and composition gradients [13].

Table 2: Research Reagent Solutions for XPS Surface Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Indium Foil | Substrate for powder mounting | Provides conductive substrate; malleable for pressing powders [2] |

| Double-sided Conductive Tape | Sample mounting | Provides electrical contact for charge stabilization; must be UHV-compatible |

| Argon Gas Cluster Ion Source | Surface cleaning & depth profiling | Enables depth profiling of organic and polymeric materials [10] [7] |

| Charge Neutralization Electron Flood Gun | Charge compensation | Essential for analysis of insulating samples to prevent peak shifting [10] |

| Certified Reference Materials | Energy scale calibration | Au, Ag, Cu foils with known binding energies for instrument calibration [14] |

| Adventitious Carbon Reference | Charge reference | Natural hydrocarbon contamination used for energy scale correction (C 1s = 284.8 eV) [15] |

Advanced Applications in Surface Sensitivity

Surface Contamination Analysis

XPS is exceptionally valuable for detecting and quantifying surface contaminants that can significantly impact material performance, particularly in pharmaceutical and biomedical applications. The technique can identify trace contamination that could disrupt manufacturing processes, leading to product failures [8]. For example, in a case study examining metal surfaces cleaned with different detergents, XPS was used to determine surface cleanliness by measuring the carbon-to-metal (C/M) ratio, where higher ratios indicated residual hydrocarbon contamination [8]. This application is critical in drug development where surface cleanliness can affect biocompatibility, adhesion, and coating uniformity.

Thin Film and Interface Characterization

The extreme surface sensitivity of XPS makes it ideal for investigating thin films and interfaces relevant to drug delivery systems and medical devices. By employing angle-resolved XPS (ARXPS), researchers can non-destructively determine the thickness and composition of ultra-thin films in the nanometer range [10] [7]. This capability is particularly valuable for studying self-assembled monolayers, polymer coatings, and surface functionalization strategies used to modify material properties for specific biological responses.

Surface Oxidation and Passivation Studies

The formation of thin oxide layers on material surfaces significantly influences their chemical stability and biological interactions. XPS has been extensively used to study passive films on metals and alloys, such as the spontaneous formation of a 2-5 nm protective oxide layer on stainless steels [13]. Using a three-layer model (contamination layer/oxy-hydroxide layer/metallic substrate), researchers can calculate film thickness and composition from a single XPS analysis, providing crucial information about material stability in physiological environments [13].

Technical Considerations and Methodological Challenges

Charge Compensation for Insulating Samples

When analyzing electrically insulating materials, the emission of photoelectrons causes positive charge to accumulate at the surface, severely affecting the XPS spectrum through peak shifting and broadening [10]. Charge compensation neutralizes this effect by supplying low-energy electrons from an external source, stabilizing the surface potential to within a few electron volts of the neutral state [10] [7]. This is particularly important for pharmaceutical materials, polymers, and ceramics that lack electrical conductivity.

Radiation Damage and Sample Degradation

Some materials, particularly certain polymers, catalysts, and highly oxygenated compounds, can undergo degradation during XPS analysis [2]. This degradation depends on the material's sensitivity to the X-ray wavelength, total X-ray dose, surface temperature, and vacuum conditions. Monochromatic X-ray sources reduce degradation by eliminating Bremsstrahlung X-rays and reducing sample heating [2]. Researchers should optimize analysis conditions (reduced power, rapid analysis) for sensitive materials and always document potential radiation effects.

Quantification and Data Interpretation

While XPS provides excellent quantitative accuracy for homogeneous materials (90-95% for major constituents), several factors must be considered for accurate quantification [2]. These include signal-to-noise ratio, peak intensity, accuracy of relative sensitivity factors, correction for electron transmission function, surface volume homogeneity, and correction for energy dependence of electron mean free path [2]. Proper background subtraction, peak fitting procedures, and awareness of common errors in data analysis are essential for reliable results [14].

Diagram 1: XPS Surface Analysis Fundamental Process.

Diagram 2: Angle-Resolved XPS for Depth Profiling.

XPS provides unparalleled capability for probing the top 1-10 nm of materials, delivering both elemental composition and chemical state information with high quantitative accuracy. The technique's extreme surface sensitivity, rooted in the short inelastic mean free path of electrons in solids, makes it indispensable for investigating surface contamination, thin films, oxidation states, and functionalization strategies. When properly executed using standardized protocols with appropriate controls and calibration, XPS surface analysis generates reliable data critical for advancing materials research, pharmaceutical development, and surface science. The continuing development of techniques such as angle-resolved XPS, small-area analysis, and advanced charge compensation further enhances the utility of XPS for characterizing the complex surface chemistry that governs material behavior in technological and biological environments.

Core Principles of XPS

X-ray Photoelectron Spectroscopy (XPS) is a surface-sensitive analytical technique that provides quantitative elemental and chemical state information from the top ~10 nm of a material. Its operation is based on the photoelectric effect, where a sample irradiated with X-rays emits photoelectrons. The analysis of these electrons' kinetic energy allows for the determination of their core-level binding energy, a unique identifier for elements and their chemical environment [16].

The fundamental relationship in XPS is the photoelectric equation, which connects the measured kinetic energy of the ejected electron to its original binding energy in the atom:

Eb = hν - Ek - φ

- Eb: The binding energy of the electron, measured in electronvolts (eV). This is the energy that held the electron in the atom, and it is the primary output of an XPS spectrum [17] [16].

- hν: The known energy of the incident X-ray photon, measured in eV [17] [16].

- Ek: The measured kinetic energy of the photoelectron, measured in eV, as detected by the instrument [17] [16].

- φ: The work function of the spectrometer, a correction factor specific to the instrument's material, measured in eV [17] [16].

The presence of atoms is determined by identifying characteristic peaks in a spectrum of electron counts versus binding energy. The intensity of these peaks is related to the concentration of the element, while the precise binding energy value reveals the chemical state of the atom, a phenomenon known as a chemical shift [16]. For example, the binding energy of a carbon 1s electron in a C-H bond is measurably different from that in a C=O bond, allowing XPS to distinguish between different chemical functionalities [18].

Quantitative Data Tables

Table 1: Characteristic Binding Energies of Core Electron Levels

This table provides representative binding energies for principal photoelectron peaks of common elements. Note that these values can shift due to chemical state.

| Element & Transition | Approximate Binding Energy (eV) | Chemical State / Notes |

|---|---|---|

| Carbon C 1s | 285.0 | Reference for hydrocarbon (C-C, C-H) [18] |

| ~288 - 290 | Carboxyl (O-C=O), Carbonyl (C=O) [18] | |

| Oxygen O 1s | 530 - 531 | Metal oxides [16] |

| 532 - 533 | Organic oxygen (e.g., O-C=O) [16] | |

| Nitrogen N 1s | 399.4 / 400.7 | Example from N₂ on Ni(100), showing a 1.3 eV chemical shift [17] |

| Silicon Si 2p | ~99 | Elemental Silicon [18] |

| 103 - 104 | Silicon Dioxide (SiO₂) [18] |

Table 2: XPS Acquisition Method Comparison

XPS data can be acquired in two primary modes, each with distinct advantages for imaging and spectroscopy [19].

| Parameter | Serial Acquisition (Mapping) | Parallel Acquisition (Imaging) |

|---|---|---|

| Method Principle | Collects a rectangular array of small-area XPS analyses point-by-point [19] | Simultaneously images the entire field of view using a 2D detector [19] |

| Spatial Resolution | Determined by smallest analysis area (e.g., 10 μm) [19] | Determined by spherical aberrations in the electron lens [19] |

| Data Output | Can collect a full spectrum at each pixel [19] | Collects an image at a single energy; a spectrum requires a series of images [19] |

| Key Advantage | Energy of X-ray beam and lens transmission are constant across the map [19] | Best possible imaging resolution and faster for single-energy images [19] |

Experimental Protocols

Protocol 1: Routine Elemental Surface Survey Analysis

Objective: To identify all elements present on the surface of a solid sample (e.g., a pharmaceutical active ingredient or a metal implant).

Materials:

- XPS instrument with a monochromatic Al K-alpha X-ray source [19]

- Sample stub and appropriate adhesive or mounting method

- Charge neutralization system (for insulating samples)

Methodology:

- Sample Preparation: Mount the sample securely on the holder to ensure good electrical and thermal contact. For powders, use a double-sided adhesive tape or press into an indium foil.

- Load and Pump: Introduce the sample into the introduction chamber and pump down to ultra-high vacuum (UHV), typically below 10⁻⁸ mbar.

- Instrument Setup:

- Select the monochromatic Al K-alpha X-ray source (hν = 1486.6 eV).

- Set the analyzer pass energy to a high value (e.g., 100-150 eV) to maximize sensitivity for the survey scan.

- Engage the charge neutralizer if the sample is an electrical insulator.

- Data Acquisition:

- Position the analysis area on a representative region of the sample.

- Acquire a survey spectrum over a wide binding energy range (e.g., 0-1200 eV).

- Ensure sufficient signal-to-noise ratio by adjusting the scan number or dwell time.

- Data Analysis:

- Identify all visible peaks by comparing their binding energies to standard databases [18].

- Note the presence of Auger lines (e.g., OKLL, C KVV) which can aid in element identification.

Protocol 2: High-Resolution Chemical State Analysis

Objective: To determine the chemical state and relative abundance of different species of a specific element.

Materials:

- As in Protocol 1.

Methodology:

- Preliminary Analysis: First, complete a survey scan as per Protocol 1 to identify elements of interest.

- Instrument Setup:

- Set the analyzer pass energy to a low value (e.g., 20-50 eV) to achieve high energy resolution.

- Data Acquisition:

- For each element of interest (e.g., C 1s, O 1s, N 1s), acquire a high-resolution spectrum over a narrow binding energy window (e.g., 15-30 eV range).

- Use a sufficient number of scans to achieve excellent signal-to-noise for accurate peak fitting.

- Data Analysis (Peak Fitting):

- Subtract a linear or Shirley background from the spectral region.

- Use a least-squares fitting routine with appropriate Gaussian-Lorentzian line shapes.

- Constrain the fit with knowledge of chemical shifts, spin-orbit splitting (e.g., for p, d, f orbitals), and fixed full-width-at-half-maximum (FWHM) where justified. Reference databases of chemical shifts are essential for this step [18].

Protocol 3: XPS Imaging for Spatial Distribution Mapping

Objective: To visualize the lateral distribution of elements or chemical states across a sample surface.

Materials:

- XPS instrument capable of serial mapping or parallel imaging [19].

Methodology:

- Define Region of Interest (ROI): Using an optical camera or secondary electron image, select the area on the sample to be mapped.

- Choose Acquisition Mode:

- Serial Mapping: Define a 2D rectangular array of points. The instrument will acquire a spectrum (or a specific peak area) at each pixel by moving the sample stage or scanning the electron optics [19].

- Parallel Imaging: The entire field of view is imaged simultaneously onto a 2D detector. Tune the analyzer to the kinetic energy corresponding to the photoelectron peak of interest to form a chemical image [19].

- Data Acquisition:

- For serial mapping, select the step size and dwell time per pixel. This method is slower but can provide a full spectrum at each pixel [19].

- For parallel imaging, the process is faster for a single energy but requires collecting a stack of images at different energies to generate spectra per pixel [19].

- Data Analysis:

- Generate elemental or chemical state maps by integrating the peak area at each pixel.

- Overlay images from different elements to assess co-localization.

Visualization Diagrams

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials for XPS Analysis

| Item | Function & Application Notes |

|---|---|

| Monochromated Al K-alpha X-ray Source | Standard source for high-resolution XPS; provides monoenergetic X-rays (1486.6 eV) to minimize peak broadening and satellite features [19]. |

| Charge Neutralization (Flood) Gun | Essential for analyzing insulating samples (e.g., polymers, ceramics) by providing low-energy electrons/ions to compensate for positive surface charge build-up during analysis. |

| Dual-Mode Sputter Ion Source | Provides ion beams (e.g., Ar⁺, C₆₀⁺) for depth profiling (cleaning surface contaminants) or for etching through layers to reveal subsurface composition [19]. |

| Reference Material (e.g., Clean Au, Ag, Cu foil) | Used for instrument calibration and energy scale verification to ensure accuracy of reported binding energies. |

| Binding Energy Database / Spectral Library | A comprehensive database of known binding energies and chemical shifts is critical for accurate peak identification and chemical state determination [18]. |

| Conductive Mounting Substrates (e.g., Indium foil, Cu tape) | Used for mounting powdered or non-conducting samples to facilitate charge drainage and minimize charging effects during analysis. |

Executing IUPAC-Compliant XPS Analysis: From Planning to Data Acquisition

Defining Analysis Objectives and Sample Compatibility

X-ray Photoelectron Spectroscopy (XPS) has become the most popular and widely used method of surface analysis, essential for many types of research spanning from chemistry and materials science to environmental, atmospheric, and biological systems [5]. The reliable use of XPS, however, depends critically on properly defining analysis objectives and ensuring sample compatibility at the earliest planning stages. Erroneous uses and misapplications occur frequently among inexperienced users, leading to significant reproducibility issues in the scientific literature [5]. This application note establishes structured protocols for determining whether XPS can obtain desired information and for assessing sample compatibility within the framework of IUPAC-aligned surface analysis protocols.

Defining XPS Analysis Objectives

Core Capabilities of XPS

XPS is a powerful tool to study surface properties within the top 1 to 10 nm of a material [20] [21]. The technique can measure:

- Elemental composition of all elements except hydrogen and helium [5] [21]

- Empirical formula of the surface constituents [21]

- Chemical state and oxidation state of elements from binding energy shifts [5] [20]

- Electronic state of elements within the material [21]

Key Questions for Objective Setting

Before proceeding with XPS analysis, researchers should systematically address the following critical questions to ensure the technique aligns with their research goals:

Table 1: Analysis Objective Assessment Framework

| Question Category | Specific Questions to Address | Technique Implications |

|---|---|---|

| Information Needs | What specific surface information is required? (elemental identity, chemical state, quantification?) | Determines required spectral resolution, peak-fitting complexity, and reference materials |

| Is the needed information contained within the top 1-10 nm? | Confirms XPS sampling depth appropriateness | |

| Sensitivity & Resolution | Does XPS have the needed detection sensitivity (typically 0.1-1 at%)? | Affects data collection strategy and counting statistics |

| Are there potential peak interferences that might complicate analysis? | May require high-resolution scans or complementary techniques | |

| What depth resolution is needed? | Determines need for angle-resolved XPS or depth profiling | |

| What lateral resolution is needed? | Determines need for XPS imaging/mapping capabilities |

The fundamental question every analyst must address is: "What is the purpose of this particular analysis?" [5] This requires knowing the analytical question before selecting the technique or methodology.

Sample Compatibility Assessment

Physical and Chemical Compatibility Factors

Sample compatibility with XPS instrumentation and vacuum requirements represents a critical step in analysis planning. The following factors must be considered:

Table 2: Sample Compatibility Assessment

| Compatibility Factor | Requirements & Considerations | Potential Solutions |

|---|---|---|

| Vacuum Compatibility | Must withstand UHV conditions (typically 10⁻⁸ to 10⁻⁹ mbar) | Environmental chambers or near-ambient pressure XPS for sensitive samples |

| Size & Form | Typical maximum dimensions determined by instrument stage | Size reduction may be required; non-standard samples may need special holders |

| Volatility | Low vapor pressure at room temperature and under UHV | Cooling stages for volatile materials; quick introduction systems |

| Stability | Must withstand X-ray irradiation for analysis duration | Lower power X-ray sources; reduced analysis time; cryo-cooling |

| Electrical Properties | Conducting vs. insulating characteristics | Charge compensation system required for insulating samples [21] |

Sample Handling and Preparation Considerations

The history of sample handling significantly impacts the ability to obtain meaningful surface information [5]. Key considerations include:

- Surface contamination from atmospheric exposure, packaging, or handling can obscure the true surface chemistry of interest

- Intentional surface treatments prior to analysis must be documented and considered in data interpretation

- Sample preparation methods must preserve the surface chemistry of interest while making the sample compatible with UHV requirements

Experimental Protocols for Compatibility Verification

Pre-Analysis Checklist Protocol

- Define primary analysis question: Clearly articulate the specific surface chemistry information required

- Verify surface sensitivity: Confirm the information needed resides within the top 10 nm of the material

- Assess vacuum compatibility: Evaluate sample volatility and outgassing potential

- Determine electrical properties: Identify whether sample is conducting or insulating to plan for charge compensation

- Evaluate radiation sensitivity: Test sample stability under X-ray exposure through short test analysis

- Verify dimensional compatibility: Confirm sample fits instrument stage and manipulation capabilities

- Document sample history: Record all handling, preparation, and storage conditions

Sample Preparation Workflow

The following workflow outlines the decision process for sample preparation and compatibility assessment:

Advanced Compatibility Considerations for Specialized Applications

Specialized XPS Techniques for Challenging Samples

Several advanced XPS methodologies extend compatibility to challenging sample types:

- Hard X-ray photoelectron spectroscopy (HAXPES): Employing higher energy X-rays (Ag Lα) enables deeper analysis and access to core levels otherwise inaccessible [21]

- Near-ambient pressure XPS: Allows analysis of samples that would degrade under ultra-high vacuum conditions [5]

- Cryogenic stages: Enable analysis of volatile materials and radiation-sensitive samples [5]

- Gas cluster ion sources: Enable depth profiling of soft materials previously inaccessible to XPS depth profiling [22] [21]

Complementary Techniques for Comprehensive Analysis

When XPS alone cannot address all analytical questions, correlative approaches with complementary techniques provide enhanced information:

- SEM/EDX integration: Provides structural context and bulk composition information [21]

- UPS (Ultraviolet Photoelectron Spectroscopy): Delivers valence band electronic structure information [22] [21]

- REELS (Reflection Electron Energy Loss Spectroscopy): Offers band gap and electronic structure data [22] [21]

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Materials for XPS Analysis

| Item/Reagent | Function/Purpose | Application Notes |

|---|---|---|

| Conductive Adhesive Tapes | Sample mounting and electrical grounding | Critical for charge stabilization; selection depends on sample compatibility |

| Reference Materials | Energy scale calibration and method validation | Au, Ag, Cu foils with well-characterized peak positions |

| Charge Neutralization Flood Gun | Electron source for insulating samples | Essential for non-conductive materials; requires optimization [21] |

| Gas Cluster Ion Source | Depth profiling of organic and soft materials | Prevents damage common with monatomic sources [22] [21] |

| Cryogenic Cooling Stage | Analysis of volatile and sensitive materials | Reduces degradation and outgassing in UHV |

| Focused Ion Beam Source | Sample cleaning and depth profiling | Interface analysis; surface contamination removal |

| Calibration Standards | Quantification verification and instrument performance | Certified reference materials with known surface composition |

Documentation and Reporting Requirements

For reproducible and reliable XPS analysis, comprehensive documentation must accompany all experiments:

- Sample history: Complete record of preparation, handling, and storage conditions

- Instrument specifications: Manufacturer, model, and key specifications

- Analysis parameters: X-ray source characteristics, charge neutralization conditions, acquisition settings

- Calibration details: Energy scale calibration method and reference materials used

- Data analysis methods: Peak-fitting parameters, background subtraction methods, quantification approaches

Proper documentation ensures analytical reproducibility and enables other researchers to verify and build upon reported findings [5].

IUPAC and ASTM Standards for Instrument Calibration and Performance Verification

The pursuit of reproducible and reliable scientific data in surface analysis requires rigorous instrument calibration and performance verification. For X-ray photoelectron spectroscopy (XPS), the most widely used surface-analysis technique, adherence to standards developed by international bodies such as the International Organization for Standardization (ISO) and ASTM International is fundamental to ensuring data comparability across laboratories and instruments [5]. The growing recognition of a "significant reproducibility crisis" in science underscores the critical importance of standardized measurement protocols, particularly for techniques like XPS that provide essential chemical state information from the outermost layers of a sample [5].

Standardized practices for XPS are primarily developed by ASTM Committee E-42 on Surface Analysis and ISO Technical Committee 201 [5]. These standards provide comprehensive guidance on instrument calibration, data acquisition, and interpretation, enabling analysts to produce reliable XPS data that withstands scientific and regulatory scrutiny. The implementation of these standards is especially crucial in regulated industries like pharmaceutical development, where method validation is essential for regulatory approval [23] [24].

Key Standardization Organizations and Their Roles

Multiple international organizations contribute to developing and maintaining standards for analytical instrumentation, including XPS. These organizations operate through consensus-based approaches involving manufacturers, users, and regulatory stakeholders.

Table 1: Key International Standardization Organizations Relevant to XPS

| Organization | Full Name | Primary Role in XPS Standardization |

|---|---|---|

| ISO/TC 201 | International Organization for Standardization/Technical Committee 201 | Develops international standards for surface chemical analysis, including XPS [5] |

| ASTM E-42 | ASTM International Committee E-42 on Surface Analysis | Develops standard practices, guides, and test methods for surface analysis [5] |

| IUPAC | International Union of Pure and Applied Chemistry | Establishes standardized chemical nomenclature and measurement methods [24] |

| BIPM | International Bureau of Weights and Measures | Coordinates international measurement traceability through national metrology institutes [24] |

The collaboration between these organizations creates a framework for measurement traceability. National Metrology Institutes (NMIs) maintain primary standards and participate in key comparisons coordinated by BIPM to ensure competence in specific measurement methods, which subsequently supports the production of reference materials and development of standards [24]. For nanomaterials and advanced materials, this hierarchical approach to measurement traceability is particularly important as it provides confidence in characterization data required for regulatory approval processes [24].

Critical Considerations for XPS Measurements

Determining Analytical Suitability and Measurement Planning

Before conducting XPS analyses, analysts must systematically evaluate whether the technique can address the specific analytical question. Key considerations include:

- Information Requirements: Determine whether the needed information is elemental composition, chemical state identification, depth distribution, or surface uniformity [5] [25].

- Sample Compatibility: Assess whether the sample size, morphology, and volatility are compatible with vacuum requirements of XPS instrumentation [5].

- Sensitivity and Detection Limits: Evaluate whether XPS has sufficient sensitivity for the elements of interest, considering typical detection limits of 0.1-1 at.% [5] [26].

- Spatial Resolution Requirements: Determine whether macro-scale analysis suffices or if micro-scale mapping or small-spot analysis is necessary [26].

- Depth Resolution Needs: Decide whether angle-resolved measurements, sputter depth profiling, or higher-energy X-rays are required to obtain depth-dependent information [5].

A comprehensive data collection plan should outline specific spectrum types needed (survey scans, high-resolution regional scans), measurement parameters, and whether specialized approaches like angle-resolved XPS or imaging are required [5].

Instrument Performance Verification and Calibration

Regular verification of instrument performance is essential for generating reliable XPS data. Critical calibration procedures include:

- Energy Scale Calibration: Verify binding energy scale accuracy using well-characterized standard materials with known peak positions [5].

- Intensity Response Calibration: Confirm the relative sensitivity factors and instrument transmission function using standard reference materials [5].

- Spectral Resolution Verification: Ensure the instrument achieves specified resolution using standard samples with narrow peak widths [5].

- Spatial Resolution Assessment: For imaging XPS instruments, verify spatial resolution using appropriate resolution test patterns [26].

Instrument performance should be verified regularly using certified reference materials or secondary standards traceable to national measurement institutes. This practice detects performance degradation from component aging or instrument malfunctions [23] [5].

Experimental Protocols for XPS Calibration and Performance Verification

Comprehensive XPS Instrument Qualification Protocol

This protocol outlines a systematic approach for verifying XPS instrument performance according to standardized practices, with execution time of approximately 8-12 hours.

Materials and Equipment

- Certified reference materials for XPS (e.g., pure copper, gold, or certified oxides)

- Conductive substrates (silicon wafers, metal foils)

- Standard sample holder compatible with the XPS instrument

- Charge compensation source (for insulating samples)

- Data analysis software with peak fitting capabilities

Table 2: Research Reagent Solutions for XPS Performance Verification

| Material/Reagent | Function | Application Example |

|---|---|---|

| Pure metal foils (Au, Ag, Cu) | Energy scale calibration | Verify binding energy scale accuracy using well-characterized peaks [5] |

| Certified reference materials | Intensity and resolution verification | Quantify instrument response function and relative sensitivity factors [5] |

| Insulating standard samples (SiO₂, polymers) | Charge compensation assessment | Evaluate effectiveness of charge neutralization systems [5] [25] |

| Resolution test patterns | Spatial resolution verification | Determine spatial resolution for imaging XPS systems [26] |

Step-by-Step Procedure

Sample Preparation

- Clean reference samples according to established protocols (e.g., solvent cleaning, argon sputtering)

- Mount samples on appropriate holders using conductive adhesives or clips when necessary

- Ensure good electrical connection between sample and holder, especially for insulating materials

Instrument Setup

- Verify ultra-high vacuum conditions (typically ≤ 1 × 10⁻⁸ mbar)

- Select appropriate X-ray source (monochromatic Al Kα typically recommended for high-resolution work)

- Configure charge neutralization system if analyzing insulating samples