Surface Chemistry of Bi₂Te₃: A Comparative Analysis of Hydrothermal and Thermolysis Synthesis Routes

This article provides a comprehensive comparative analysis of the surface chemistry and material properties of Bismuth Telluride (Bi₂Te₃) nanostructures synthesized via hydrothermal and thermolysis methods.

Surface Chemistry of Bi₂Te₃: A Comparative Analysis of Hydrothermal and Thermolysis Synthesis Routes

Abstract

This article provides a comprehensive comparative analysis of the surface chemistry and material properties of Bismuth Telluride (Bi₂Te₃) nanostructures synthesized via hydrothermal and thermolysis methods. Tailored for researchers and scientists in materials science and engineering, it explores the foundational principles, mechanistic pathways, and key reaction parameters governing each technique. The scope extends to detailed methodological protocols, troubleshooting common synthesis challenges, and strategies for optimizing surface characteristics and nanostructural morphology. A critical validation and comparison of the resulting materials' thermoelectric performance, crystallinity, and surface states is presented, drawing on recent advances including microwave-assisted thermolysis and green hydrothermal synthesis. The findings offer essential insights for selecting and refining synthesis routes to engineer Bi₂Te₃ with tailored properties for advanced thermoelectric and potential biomedical applications.

Core Principles and Reaction Mechanisms of Bi₂Te₃ Synthesis

Bismuth Telluride (Bi₂Te₃) stands as a cornerstone material in the field of thermoelectrics and topological insulators. Its performance is intrinsically linked to its unique crystal structure, which gives rise to pronounced anisotropic properties. This guide provides a comparative analysis of Bi₂Te₃, focusing on the fundamental chemistry that governs its behavior. It objectively compares material performance based on synthesis route—specifically within the context of hydrothermal versus thermolysis methods—and provides supporting experimental data on its anisotropic electronic and thermal transport properties. Understanding these structure-property relationships is crucial for researchers and scientists aiming to optimize this material for advanced applications in energy harvesting and electronics.

Quintessential Crystal Structure

The defining feature of Bi₂Te₃ is its layered, rhombohedral crystal structure (space group R3m), which is often represented in a hexagonal setting. [1] [2] The unit cell parameters are a = 3.8 Å and c = 30.5 Å. [2] This structure is composed of quintuple layers (QLs), typically about 1 nm thick, stacked along the c-axis. [3] Each QL has a sequence of atoms in the order Te(1)-Bi-Te(2)-Bi-Te(1).[ [2]]

Within a single QL, the atomic bonds between Te and Bi atoms are strong, covalent interactions. [2] Critically, the adjacent QLs are held together by weak van der Waals forces between the two Te(1) layers. [3] [2] This stark difference in bonding strength—strong covalent within a QL versus weak van der Waals between QLs—is the origin of the material's structural and property anisotropy. This anisotropic character manifests in various properties, including anisotropic sublimation during thermal annealing and highly directional electronic and thermal transport. [3]

- Strong Covalent Bonds exist within each Quintuple Layer (Te-Bi-Te-Bi-Te).

- Weak Van der Waals Forces act between the Te(1) atoms of adjacent Quintuple Layers.

- The c-axis is the crystallographic direction of stacking, along which the weak interlayer forces lead to easy cleavage and anisotropic properties.

Synthesis Routes: A Comparative Analysis

The synthesis method significantly influences the morphology, defect density, and ultimately the thermoelectric performance of Bi₂Te₃. The hydrothermal and thermolysis routes represent two prominent solution-based chemical approaches.

Experimental Protocols for Synthesis

Microwave-Assisted Thermolysis Synthesis of Bi₂Te₃: [4]

- Te Precursor Solution: A tellurium powder is complexed with tri-butyl phosphine (TBP) by heating the mixture to 220 °C using microwave irradiation (400 W) with constant stirring until complete dissolution.

- Bi Precursor Solution: In a separate vial, bismuth chloride (BiCl₃) is dissolved in oleic acid under continuous stirring for 30 minutes.

- Reaction Mixture: The Bi precursor solution is transferred to a Teflon vessel, and 1-Octadecene is added. The dissolved Te precursor is then injected into this vessel.

- Microwave Thermolysis: The mixture is heated using a microwave reactor (1800 W) to a reaction temperature of 220 °C with a ramp time of 4 minutes and a dwell time of 2 minutes.

- Purification: The resulting product is washed multiple times with a mixture of acetone and isopropanol and collected via centrifugation.

Hydrothermal Synthesis of Bi₂Te₃ (General Protocol): While the specific protocol from the comparative study is not fully detailed in the search results, the hydrothermal method generally involves the following steps. [5]

- Precursor Preparation: Aqueous solutions of bismuth and tellurium precursors are prepared and mixed in an autoclave.

- Reaction: The autoclave is sealed and heated to a specific reaction temperature (e.g., 160-200 °C) for a prolonged period (several hours to days), utilizing the self-generated pressure to facilitate the reaction.

- Cooling and Collection: The autoclave is allowed to cool to room temperature naturally. The resulting precipitate is collected and washed repeatedly with deionized water and ethanol, then dried to obtain the final powder.

Key Reagents and Their Functions

Table 1: Essential Research Reagents for Bi₂Te₃ Synthesis

| Reagent Name | Function in Synthesis | Application in Route |

|---|---|---|

| Bismuth Chloride (BiCl₃) | Bismuth (Bi³⁺) ion source | Thermolysis [4] & Hydrothermal [5] |

| Tellurium (Te) Powder | Tellurium ion source | Thermolysis [4] & Hydrothermal [5] |

| Tri-butyl Phosphine (TBP) | Complexing agent to dissolve Te powder | Thermolysis [4] |

| Oleic Acid | Surfactant and stabilizing agent to control particle growth and prevent agglomeration | Thermolysis [4] |

| 1-Octadecene (ODE) | Non-polar solvent for high-temperature reactions | Thermolysis [4] |

| Poly(vynilpirrolidone) (PVP) | Polymer surfactant to control morphology and stabilize nanoparticles | Thermolysis (some routes) [3] |

Comparative Performance of Synthesized Materials

The choice of synthesis method directly impacts the material's characteristics and its performance in devices.

Table 2: Comparison of Hydrothermal vs. Thermolysis Synthesis Routes

| Parameter | Hydrothermal Route | Thermolysis Route | Implications for Performance |

|---|---|---|---|

| General Morphology | Varies (platelets, particles) | Platelet-like, hexagonal nanocrystals [3] | Morphology influences packing and charge transport. |

| Surface Chemistry | Differs from thermolysis; impacts EPD [5] | Often organic ligand-capped (e.g., PVP, Oleic Acid) [3] [4] | Surface chemistry affects dispersion, film formation (EPD), and sintering. |

| Crystallinity | Crystalline | Highly crystalline [3] | Higher crystallinity generally improves electrical conductivity. |

| Scalability | Established for scalable production | Highly scalable and rapid (microwave-assisted) [4] | Thermolysis offers a time- and energy-efficient high-throughput path. [4] |

| Typical ZT Value | Data not fully available | 0.7 (for n-type Bi₂Te₃ consolidated via SPS at 573 K) [4] | Demonstrates high performance achievable from thermolysis-synthesized powder. |

Anisotropic Properties and Experimental Characterization

The weak van der Waals gaps and strong in-plane bonding create a system where properties differ dramatically when measured along different crystallographic directions.

Anisotropic Sublimation and Thermal Stability

Experimental Protocol: In-situ TEM Annealing [3]

- Objective: To study the thermal stability and sublimation mechanisms of 2D Bi₂Te₃ nanocrystals.

- Method: Platelet-like nanocrystals were annealed directly within a transmission electron microscope (TEM) column under high vacuum (1.8 × 10⁻⁵ Pa) at temperatures between 350 °C and 500 °C for 30-120 minutes.

- Observations: The sublimation process was highly anisotropic. It commenced at the prismatic {011̅0} facet edges and progressed along the ⟨2̅110⟩ directions, preferentially consuming these facets while the basal {0001} planes remained more stable. [3]

- Supporting Theory: Density Functional Theory (DFT) calculations confirmed that the sublimation of the {011̅0} facets is energetically more favorable, occurring at a rate estimated to be about 700 times faster than the sublimation of the {0001} planes at the annealing temperatures used. [3] This explains the observed morphological changes and highlights the intrinsic anisotropy of the crystal's surface free energy.

Anisotropic Thermoelectric Transport Properties

The electrical and thermal transport properties are highly direction-dependent, a critical factor for device design.

Experimental Protocol: Measuring Anisotropy in Oriented Films [2]

- Sample Preparation: Highly oriented [110] Bi₂Te₃ films were fabricated using pulsed electrodeposition, resulting in a columnar morphology.

- In-plane Measurements: The Seebeck coefficient and electrical resistivity parallel to the substrate plane were measured using a commercial Linseis LSR-3 system. The thermal conductivity was measured using time-domain thermoreflectance (TDTR).

- Out-of-plane Measurements: A specialized setup involving a COMSOL simulation model was used to extract the electrical conductivity perpendicular to the substrate plane.

Table 3: Anisotropic Thermoelectric Properties of Electrodeposited Bi₂Te₃ Films at 300 K [2]

| Property | In-plane (∥ to substrate) | Out-of-plane (⊥ to substrate) | Anisotropy Ratio (Out-of-plane / In-plane) |

|---|---|---|---|

| Electrical Conductivity, σ | (6.7 ± 0.7) × 10⁴ S/m | (3.2 ± 0.4) × 10⁵ S/m | ~4.8 |

| Seebeck Coefficient, S | -58 ± 4 μV/K | -50 ± 5 μV/K | ~0.86 (Nearly Isotropic) |

| Power Factor, S²σ | 225 ± 32 μW/m·K² | 800 ± 189 μW/m·K² | ~3.6 |

| Figure of Merit, zT | (5.6 ± 1.2) × 10⁻² | (10.4 ± 2.6) × 10⁻² | ~1.9 |

The data demonstrates that the electrical conductivity is significantly higher in the out-of-plane direction (perpendicular to the c-axis) than in the in-plane direction. This is because charge carriers move more easily across the quintuple layers than between them. Conversely, the Seebeck coefficient remains largely isotropic. The combined effect leads to a power factor and figure of merit (zT) that are substantially higher in the out-of-plane direction for these specific oriented films. [2]

The fundamental chemistry of Bi₂Te₃, defined by its quintuple-layer crystal structure with alternating covalent and van der Waals bonding, is the direct cause of its pronounced chemical and physical anisotropy. This comparative guide demonstrates that synthesis routes like thermolysis and hydrothermal methods can produce high-quality materials with distinct surface chemistries and morphologies. The experimental data unequivocally shows that properties such as sublimation behavior, electrical conductivity, and overall thermoelectric efficiency are highly direction-dependent. For researchers designing devices, this means that controlling both the synthesis and the crystallographic orientation of Bi₂Te₃ is not merely beneficial—it is essential for unlocking peak performance. Future research will continue to refine these synthesis techniques and deepen our understanding of the surface chemistry to further enhance the properties of this versatile material.

The synthesis of functional nanomaterials with precise control over their morphology and size is a cornerstone of modern materials science. Among various fabrication techniques, hydrothermal synthesis has emerged as a powerful aqueous-based approach for the nucleation and growth of crystalline materials, particularly for thermoelectric applications. This method utilizes a pressure vessel to create a high-temperature, high-pressure aqueous environment that facilitates chemical reactions normally impossible under ambient conditions. Its simplicity, cost-effectiveness, and environmental friendliness compared to many other synthesis routes make it particularly attractive for producing nanostructured materials [6].

Within the context of bismuth telluride (Bi₂Te₃)—a benchmark thermoelectric material for near-room-temperature applications—understanding the comparative performance of hydrothermal synthesis against other methods is crucial for advancing thermoelectric technology. This guide provides an objective comparison between hydrothermal and thermolysis-based synthesis routes for Bi₂Te₃, focusing on their experimental protocols, resulting material characteristics, and thermoelectric performance, supported by recent experimental data.

Fundamental Principles of Hydrothermal Synthesis

Hydrothermal synthesis is a solution-based reaction process conducted in a sealed vessel (autoclave) where an aqueous precursor solution is heated above the normal boiling point of water to generate autogenous pressure. This creates a unique environment that enhances the solubility of solid precursors and accelerates reaction kinetics, facilitating the nucleation and growth of crystalline phases. The method is characterized by its low equipment and operating requirements, low cost, and low synthesis temperatures, which collectively help yield less-contaminated nanomaterials with tuned chemical compositions [6].

The crystal growth mechanism in hydrothermal synthesis is profoundly influenced by the intrinsic crystal structure of the target material. For Bi₂Te₃, which possesses a rhombohedral crystal structure (space group R-3m) with a hexagonal unit cell, the growth is inherently anisotropic [7] [8]. The unit cell consists of quintuple atomic layers (Te¹⁻Bi⁻Te²⁻Bi⁻Te¹) stacked along the c-axis and held together by strong covalent bonds within the quintets and weak van der Waals forces between the Te¹ layers [7]. This structural anisotropy promotes two-dimensional crystal growth, most often resulting in the formation of hexagonal nanoplates where the basal plane is perpendicular to the c-axis [8].

Experimental Protocols: A Comparative Analysis

Detailed Hydrothermal Synthesis Protocol

A standard, reproducible protocol for the hydrothermal synthesis of Bi₂Te₃ nanoplates is as follows [9]:

Reagents:

- Bismuth source: BiCl₃ (2.0 mmol, analytical grade)

- Tellurium source: TeO₂ (3.0 mmol, analytical grade)

- Reducing agent: NaBH₄ or ethylene glycol (EG)

- Surfactant: Polyvinyl pyrrolidone (PVP, K-30, 1.0 g)

- Alkaline agent: NaOH (20.0 mmol)

- Solvent: Deionized water or ethylene glycol (100.00 mL)

Procedure:

- Precursor Preparation: Dissolve PVP in ethylene glycol. Add BiCl₃, TeO₂, and NaOH to the solution sequentially under constant magnetic stirring until a homogeneous mixture is obtained.

- Reaction Setup: Transfer the final precursor solution to a Teflon-lined stainless-steel autoclave, seal it securely, and place it in a preheated oven.

- Crystallization: Heat the autoclave to a temperature between 180°C and 200°C and maintain this temperature for a prolonged period (typically 24-36 hours) to allow for complete nucleation and crystal growth.

- Product Recovery: After natural cooling to room temperature, centrifuge the products to separate them from the solution. Wash the precipitate several times with deionized water, acetone, and anhydrous ethanol to remove impurities and unreacted precursors.

- Drying: Dry the final product in a vacuum oven at 60°C for 6 hours before further characterization or consolidation.

Critical Parameter - pH Control: The pH of the precursor solution significantly influences the morphology and phase purity of the final product. One comprehensive study systematically investigated 16 different pH values [6]. Their findings indicate that:

- Strongly acidic conditions (pH < 1) prevent the formation of pure Bi₂Te₃, resulting instead in a mixture of elemental Bi and Te.

- Moderately acidic to near-neutral conditions (pH = 1 to 5) yield rhombohedral Bi₂Te³ as the primary phase, though minor impurities of Bi and Te may persist.

- Alkaline conditions (pH > 9) produce pure, single-phase Bi₂Te₃ with well-defined morphologies.

The morphology evolves from irregular nanoparticles at low pH to well-defined hexagonal nanoplates, nanoflowers, and even nanotubes as the pH increases, driven by mechanisms like Ostwald ripening and imperfect oriented attachment [6].

Thermolysis Synthesis Protocol

In contrast, microwave (MW)-assisted thermolysis represents a non-aqueous, energy-efficient synthetic route characterized by rapid, volumetric heating [4] [5].

Reagents:

- Bismuth source: BiCl₃ (stoichiometric amount for 2:3 Bi:Te ratio)

- Tellurium source: Te powder (complexed with tri-butyl phosphine, TBP)

- Solvents: Oleic acid, 1-Octadecene (ODE)

- Surfactant: Thioglycolic acid (TGA)

Procedure:

- Precursor Preparation: First, complex Te powder with TBP by heating the mixture to 220°C until complete dissolution. In a separate vial, dissolve BiCl₃ in oleic acid under continuous stirring for 30 minutes.

- Mixing: Combine the Bi and Te precursor solutions with ODE and TGA in a dedicated MW reaction vessel.

- Reaction: Heat the mixture using microwave irradiation (e.g., 1800 W) to 220°C with a rapid ramp time (e.g., 4 minutes) and a short dwell time (e.g., 2 minutes).

- Product Recovery: Separate the resulting nanoparticles by centrifugation, wash with acetone and isopropanol, and dry the final powder.

The principal advantage of MW-thermolysis is its dramatically reduced reaction time—on the order of minutes rather than the hours required for hydrothermal synthesis [4].

Comparative Performance Data

The following tables consolidate key experimental data from recent studies, enabling a direct comparison of the material properties and performance achievable via these two synthetic routes.

Table 1: Comparison of Synthesis Conditions and Morphological Outcomes

| Synthesis Parameter | Hydrothermal Route | Microwave-Assisted Thermolysis |

|---|---|---|

| Reaction Solvent | Aqueous (Water/Ethylene Glycol) [9] | Non-aqueous (Oleic Acid/1-Octadecene) [4] |

| Typical Temperature | 180°C - 200°C [9] [8] | ~220°C [4] |

| Typical Duration | 24 - 36 hours [9] | Several minutes [4] |

| Primary Morphology | Hexagonal Nanoplates [8] | Nanoparticles [4] |

| Key Advantage | Low cost, simple setup, tunable morphology via pH [6] | Ultra-fast, high throughput, energy-efficient [4] |

Table 2: Comparison of Thermoelectric Properties of Consolidated Materials

| Property | Hydrothermally-Synthesized Bi₂Te₃ | Thermolysis-Synthesized Bi₂Te₃ |

|---|---|---|

| Electrical Conductivity (σ) | 18.5 - 28.7 × 10³ S/m (300-550 K) [9] | Reported, but specific values not provided in search results [5] |

| Seebeck Coefficient (S) | -90.4 to -113.3 µV/K (300-550 K) [9] | Reported, but specific values not provided in search results [5] |

| Power Factor (S²σ) | ~0.3 µW/cm·K² (for thin film) [10] | Performance is shifted to higher temperatures [4] |

| Figure of Merit (ZT) | ~1.1 (for bulk, SPS consolidated) [6] | 0.7 at 573 K (for n-type) [4] |

The Scientist's Toolkit: Essential Research Reagents

The following table details key reagents and their functions in the synthesis of Bi₂Te₃, serving as a quick reference for experimental design.

Table 3: Essential Reagents for Bi₂Te₃ Synthesis

| Reagent | Function | Example in Hydrothermal Synthesis | Example in Thermolysis |

|---|---|---|---|

| Bismuth Source | Provides Bi³⁺ ions for crystal lattice | BiCl₃ [9], Bi₂O₃ [8] | BiCl₃ [4] |

| Tellurium Source | Provides Te²⁻ ions for crystal lattice | TeO₂ [9], Te powder [6] | Te powder [4] |

| Reducing Agent | Reduces metal precursors to target oxidation state | NaBH₄, Ethylene Glycol [6] [9] | Tri-butyl phosphine (TBP) [4] |

| Surfactant | Controls morphology and inhibits aggregation | Polyvinyl Pyrrolidone (PVP) [9] [8] | Oleic Acid, Thioglycolic Acid (TGA) [4] |

| Solvent | Reaction medium | Deionized Water, Ethylene Glycol [9] | 1-Octadecene (ODE) [4] |

| pH Modifier | Controls reaction kinetics and morphology | NaOH [6] [9] | Not typically applicable |

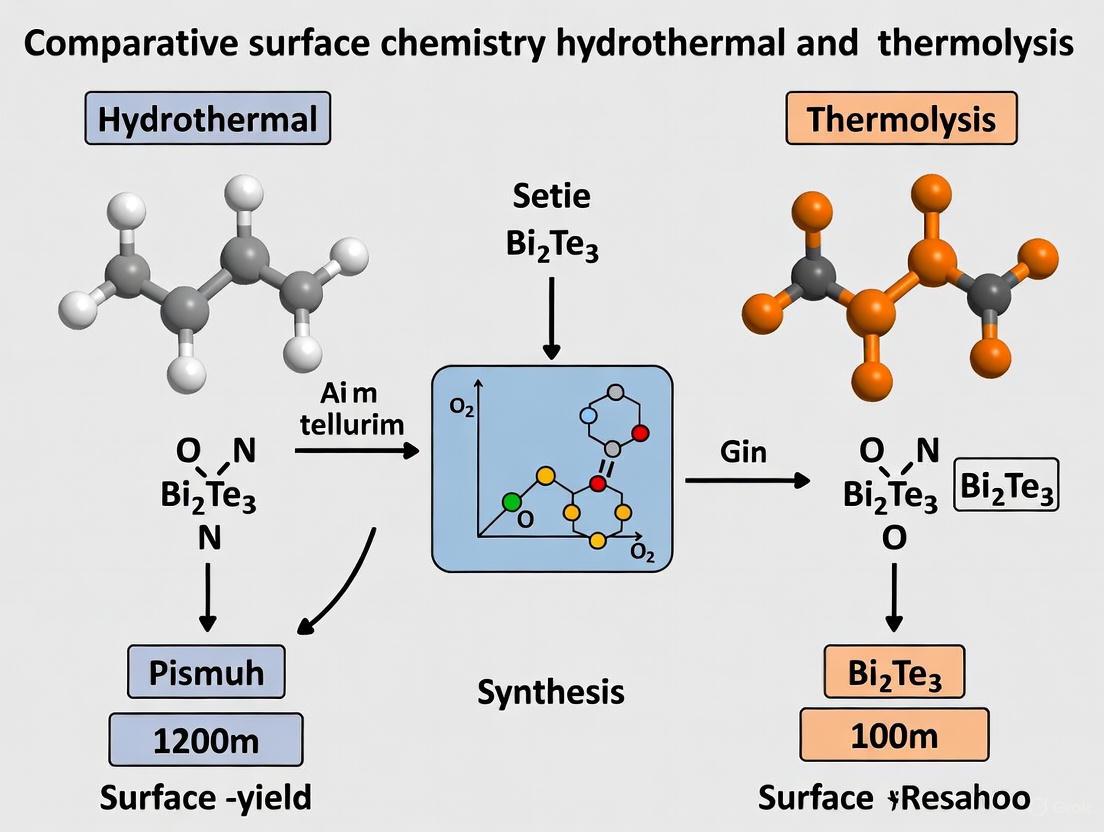

Visualizing the Synthesis Workflows and Outcomes

The following diagrams illustrate the procedural flow and comparative performance of the two synthesis methods.

Diagram 1: A side-by-side comparison of the experimental workflows for Hydrothermal and Thermolysis synthesis of Bi₂Te₃, highlighting key differences in reagents and processing times.

Diagram 2: A qualitative comparison of the performance profiles of Hydrothermal and Thermolysis synthesis methods. Green indicates a relative strength, red a relative weakness, and yellow a neutral or context-dependent characteristic.

Both hydrothermal and thermolysis synthesis routes are capable of producing high-quality Bi₂Te₃ nanomaterials with promising thermoelectric properties. The choice between them depends heavily on the research or production priorities.

- Hydrothermal synthesis excels in its cost-effectiveness, simplicity, and exceptional capacity for morphological control through parameters like pH. It is an ideal platform for fundamental studies on structure-property relationships.

- Microwave-assisted thermolysis offers a compelling advantage in speed and energy efficiency, making it a strong candidate for rapid screening and scalable, high-throughput production.

Within the broader thesis of comparative synthesis research, this analysis demonstrates that there is no single "best" method. The decision is application-dependent, hinging on the specific balance required between cost, time, control over morphology, and final thermoelectric performance. Future research may focus on hybrid approaches that leverage the strengths of both methods, such as using hydrothermally synthesized powders as precursors for further rapid thermal processing.

The synthesis of advanced nanomaterials, particularly bismuth telluride (Bi₂Te₃), has gained significant attention due to their exceptional thermoelectric properties suitable for power generation and cooling applications near room temperature. Within the broader context of comparative surface chemistry research on hydrothermal versus thermolysis synthesis of Bi₂Te₃, this guide provides an objective comparison of thermolysis synthesis techniques, specifically focusing on organometallic decomposition in non-aqueous media. Thermoelectric materials can directly convert heat into electrical energy, with Bi₂Te₃-based alloys representing the most mature and widely investigated systems for near room-temperature applications [11] [9]. The thermolysis approach, particularly microwave-assisted synthesis, has emerged as a scalable, energy-efficient alternative to traditional hydrothermal methods, offering distinct advantages in morphology control, crystallinity, and ultimately, thermoelectric performance [11].

Methodology Comparison: Hydrothermal vs. Thermolysis

Table 1: Fundamental Comparison Between Hydrothermal and Thermolysis Synthesis Methods

| Parameter | Hydrothermal Synthesis | Thermolysis Synthesis |

|---|---|---|

| Reaction Medium | Aqueous solution [6] | Non-aqueous organic solvents (e.g., 1-Octadecene, Oleic acid) [11] |

| Temperature Range | Typically 180-200°C [12] [6] | ~220°C [11] |

| Pressure | High (in sealed autoclave) [12] | Can be performed at ambient pressure [11] |

| Heating Mechanism | Conventional conductive heating [6] | Volumetric heating (microwave-assisted) [11] |

| Key Morphologies | Nanoplates, nanoflowers, nanotubes, nanospheres [6] [13] | Nanoparticles, nanoplates [11] |

| Typical Precursors | BiCl₃, TeO₂, NaBH₄ [6] | BiCl₃, Te powder complexed with TBP [11] |

| Scalability | Moderate | High (facile, high-throughput) [11] |

| Reaction Time | Several hours to tens of hours (e.g., 36h) [9] | Very fast (e.g., 4 min ramp, 2 min dwell) [11] |

Experimental Protocols

Detailed Protocol: Microwave-Assisted Thermolysis

The microwave-assisted thermolysis process represents a state-of-the-art approach for the synthesis of Bi₂Te₃ in non-aqueous media [11]. The following detailed methodology has been adapted from established procedures:

Precursor Preparation:

- Tellurium Complex: A stoichiometric amount of tellurium powder is complexed with tri-butyl phosphine (TBP, 6 mL) by heating the mixture to 220°C using microwave power (400 W) under constant stirring until the Te powder is fully dissolved [11].

- Bismuth Precursor Solution: In a separate vial, a stoichiometric amount of BiCl₃ is dissolved in oleic acid under continuous stirring for 30 minutes. This solution is then transferred to a 100 mL Teflon vessel, and 1-Octadecene (ODE) is added [11].

Synthesis Procedure:

- The prepared Te-TBP complex is added to the Bi precursor solution in the Teflon vessel.

- The mixture is heated using a high-pressure multivessel microwave reactor (e.g., Milestone flexiWAVE) to a reaction temperature of 220°C with a rapid ramp time of 4 minutes and a short dwell time of 2 minutes [11].

- After the reaction, the products are allowed to cool naturally.

- The resulting nanomaterials are washed several times with acetone and isopropanol to remove residual organics and by-products.

- The final products are collected by centrifugation and dried for further characterization and consolidation [11].

Detailed Protocol: Conventional Solvothermal Synthesis

For comparative purposes, a standard solvothermal method is outlined below:

Precursor Preparation:

- Dissolve 0.4 g of polyvinyl pyrrolidone (PVP) in 18 mL of ethylene glycol.

- Add Bi₂O₃ (0.02 mol/L) and TeO₂ (0.07 mol/L) to the solution.

- Introduce 2 mL of a concentrated NaOH solution (5.0 mol/L) [12].

Synthesis Procedure:

- Transfer the resulting precursor solution to a Teflon-lined stainless-steel autoclave and seal it.

- Heat and maintain the autoclave at a temperature between 180-200°C for 4-36 hours with magnetic stirring (e.g., 500 rpm) [12] [9].

- After synthesis, cool the products naturally below 50°C.

- Wash the residue several times with distilled water and absolute ethanol.

- Collect the products by centrifugation and dry under vacuum at 60°C for 24 hours [12].

Synthesis Workflow and Morphological Control

The following diagram illustrates the key decision points and pathways in the synthesis of Bi₂Te³ nanostructures, highlighting how choice of method and parameters dictates the final morphology.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagent Solutions and Their Functions in Bi₂Te₃ Synthesis

| Reagent | Function | Synthesis Method |

|---|---|---|

| BiCl₃ | Bismuth precursor providing Bi³⁺ ions [11] [6] | Thermolysis, Hydrothermal |

| Te Powder | Tellurium source [11] [6] | Thermolysis, Hydrothermal |

| Tri-butyl Phosphine (TBP) | Complexing agent for Te powder to enhance solubility [11] | Thermolysis |

| Oleic Acid | Solvent and capping agent to control nanoparticle growth [11] | Thermolysis |

| 1-Octadecene (ODE) | High-booint non-polar solvent for high-temperature reactions [11] | Thermolysis |

| Ethylene Glycol (EG) | Reductive solvent medium and ligand [12] [9] | Solvothermal |

| Polyvinyl Pyrrolidone (PVP) | Surfactant to control morphology and prevent agglomeration [12] [9] | Solvothermal |

| NaBH₄ | Strong reducing agent in aqueous media [6] | Hydrothermal |

| NaOH | Provides alkaline environment, influences reaction kinetics [12] [6] | Hydrothermal/Solvothermal |

Comparative Performance Analysis

Table 3: Quantitative Comparison of Synthesis Outcomes and Thermoelectric Performance

| Characteristic | Hydrothermal/Solvothermal Synthesis | Thermolysis Synthesis |

|---|---|---|

| Crystallinity | Single-crystalline nanoplates [12] | Nanocrystalline powders [11] |

| Typical Size Range | ~230-420 nm nanosheets [9] | Nanoparticles (specific size not provided) [11] |

| Morphology Control | High (nanoplates, spheres, flowers, tubes via pH) [6] [13] | Moderate (nanoparticles, nanoplates) [11] |

| Phase Purity | High purity achievable, but can contain Bi/Te impurities at extreme pH [6] | High phase purity achievable [11] |

| Electrical Conductivity (σ) | 18.5-28.69 × 10³ S/m [9] | Not explicitly reported |

| Seebeck Coefficient (S) | -90.4 to -113.3 µV/K [9] | Not explicitly reported |

| ZT Value (Figure of Merit) | ~1.1 reported for SPS-consolidated samples [6] | 0.7 at 573 K for n-type Bi₂Te₃ [11] |

| Synthesis Duration | Long (hours to tens of hours) [9] | Very short (minutes) [11] |

| Throughput Potential | Moderate | High (scalable) [11] |

The choice between thermolysis and hydrothermal synthesis methods for Bi₂Te₃ production involves significant trade-offs. Thermolysis, particularly microwave-assisted synthesis, offers remarkable advantages in scalability, energy efficiency, and speed, producing high-quality nanocrystalline materials with competitive thermoelectric performance (ZT ~ 0.7) [11]. Conversely, hydrothermal and solvothermal methods provide superior morphological diversity and control, enabling the formation of nanoplates, nanoflowers, and nanotubes through pH manipulation, albeit with longer reaction times [6]. The decision framework should prioritize thermolysis for industrial-scale production where throughput and energy consumption are critical, while reserving hydrothermal techniques for applications requiring specific nanostructured morphologies. Future research directions should focus on hybrid approaches that combine the morphological control of hydrothermal methods with the rapid kinetics of thermolysis processes.

The Critical Role of Reductants and pH in Reaction Kinetics

The synthesis of advanced functional materials, such as the thermoelectric compound bismuth telluride (Bi₂Te₃), requires precise control over reaction kinetics to achieve desired morphological and electronic properties. The selection of synthesis route—whether hydrothermal or thermolysis—fundamentally dictates the reaction environment and the subsequent role of critical parameters like reductants and pH. These parameters are not mere reaction conditions but are primary levers controlling nucleation rates, surface adsorption energies, and ultimately, the crystallinity, morphology, and performance of the final product [14] [15]. This guide provides a comparative analysis of experimental data and protocols, situating the discussion within the broader context of surface chemistry studies on Bi₂Te₃. It is designed to equip researchers with the knowledge to objectively select and optimize synthesis parameters for targeted material properties.

Synthesis Methodologies: Hydrothermal vs. Thermolysis

The fundamental distinction between hydrothermal and thermolysis routes lies in the reaction medium and the mechanism of energy transfer, which in turn influences the choice and function of reductants and pH controllers.

Hydrothermal Synthesis employs an aqueous solvent in a sealed vessel under autogenous pressure. The aqueous medium makes the reaction kinetics highly sensitive to the pH environment, which governs the solubility of precursors, the formation of intermediate complexes, and the oxidation state of metal ions [15]. Reductants in this system must be effective in water, often relying on molecules like ethylenediaminetetraacetic acid (EDTA) or polyvinyl pyrrolidone (PVP) which also frequently act as surfactants or complexing agents [10] [9].

Microwave-Assisted Thermolysis, typically a solvothermal process, uses organic solvents like ethylene glycol (EG) under microwave irradiation. The primary role of the solvent shifts towards enabling rapid, volumetric heating, which drastically accelerates reaction kinetics—from hours or days to minutes [4] [15]. In this context, the solvent itself (e.g., EG) can act as a reductant, while other additives like oleic acid and tri-butyl phosphine (TBP) are introduced to complex with metal precursors and control nanoparticle growth [4]. The need for a strongly alkaline environment persists but is adapted for the organic medium.

The following workflow delineates the generalized experimental progression for both synthesis methods, highlighting the parallel yet distinct steps involving reductants and pH control.

Figure 1: Comparative experimental workflow for the hydrothermal and thermolysis synthesis of Bi₂Te₃, highlighting the distinct roles of chemical agents at each stage.

Comparative Experimental Data and Protocols

Direct comparison of the two methods requires an examination of their specific reaction conditions, the resultant material characteristics, and thermoelectric performance.

Key Experimental Protocols

Protocol 1: Hydrothermal Synthesis of Bi₂Te₃ Hexagonal Nanoplates [9] [8]

- Precursor Preparation: Dissolve TeO₂ (0.07 mol/L) and BiCl₃ (2.0 mmol) in ethylene glycol (18 mL).

- Alkalinization and Surfactant Addition: Add a concentrated NaOH solution (e.g., 5.0 mol/L, 2 mL) to the mixture to create a strongly alkaline environment. Introduce 0.4 g of PVP as a surfactant and structure-directing agent.

- Reaction Execution: Transfer the solution to a Teflon-lined autoclave. Seal and heat at 190-200°C for 4 to 24 hours with constant stirring (e.g., 500 rpm).

- Product Recovery: After natural cooling, wash the precipitate repeatedly with distilled water and absolute ethanol. Collect the final product via centrifugation and dry under vacuum at 60°C.

Protocol 2: Microwave-Assisted Thermolysis of Bi₂Te₃ Nanoparticles [4]

- Precursor Complexation:

- Tellurium Source: Complex Te powder with tri-butyl phosphine (TBP, 6 mL) by heating at 220°C until fully dissolved.

- Bismuth Source: Separately, dissolve BiCl₃ in oleic acid under continuous stirring for 30 minutes.

- Mixing and Reaction: Combine the two precursor solutions with 1-Octadecene (ODE) in a microwave reactor. Heat using microwave irradiation (e.g., 400-1800 W) to 220°C with a rapid ramp time (e.g., 4 min) and a short dwell time (e.g., 2 min).

- Product Recovery: Cool the reaction mixture. Precipitate the nanoparticles with acetone or isopropanol, then centrifuge to collect the powder. Dry the product for further characterization and processing.

Comparative Performance Data

The table below synthesizes experimental data from various studies, providing a direct comparison of how synthesis parameters in each route influence the final material properties.

Table 1: Comparative Analysis of Hydrothermal and Thermolysis Synthesis Parameters and Outcomes for Bi₂Te₃

| Aspect | Hydrothermal Synthesis | Microwave-Assisted Thermolysis | Key Implications |

|---|---|---|---|

| Reaction Time & Energy | 4 - 24 hours [9] [8] | 2 minutes - 2 hours [4] [15] | Thermolysis offers superior energy and time efficiency, enabling rapid prototyping and scalable production. |

| Typical Solvent | Water, Ethylene Glycol (EG) [9] [8] | EG, 1-Octadecene (ODE) [4] | Solvent choice dictates reductant compatibility and heat transfer mechanism (conventional vs. microwave). |

| Critical Reductants & Surfactants | NaOH, PVP, EDTA, NaBH₄ [14] [10] [9] | Oleic Acid, Tri-butyl Phosphine (TBP) [4] | Hydrothermal: Morphology control. Thermolysis: Precursor solubilization and nanostructure nucleation. |

| pH Role | Crucial; High alkalinity (pH >11) required to form Te²⁻ ions and control morphology [15]. | Less explicitly documented, but alkaline agents (NaOH) are still used [4]. | pH is a dominant kinetic factor in hydrothermal synthesis, directly influencing precursor reactivity. |

| Common Morphologies | Hexagonal nanoplates, nanoflakes, spherical nanoparticles [13] [14] [8]. | Hexagonal nanoplatelets, nanoparticles [4] [15]. | Both methods can achieve 2D nanostructures, but hydrothermal offers finer control over pore formation [8]. |

| Crystallinity | Single-crystalline nanoplates [8]. | Highly crystalline powders [4] [15]. | Both methods yield high-quality crystals, with thermolysis achieving this orders of magnitude faster. |

| Reported ZT (Figure of Merit) | ~0.8 - 0.9 (300-375 K) [15] | ~0.7 (n-type, 573 K), ~0.9 - 1.0 (p-type, 425-525 K) [4] [15] | Both methods can achieve high ZT. Thermolysis can shift peak performance to higher temperatures [4]. |

The Scientist's Toolkit: Essential Reagents and Their Functions

The following table catalogues key reagents used in the synthesis of Bi₂Te₃, detailing their primary and secondary functions within the reaction chemistry.

Table 2: Research Reagent Solutions for Bi₂Te₃ Synthesis

| Reagent | Primary Function | Specific Role in Reaction Kinetics | Common Synthesis Route |

|---|---|---|---|

| Sodium Hydroxide (NaOH) | pH Regulator / Alkaline Agent | Creates high-pH environment essential for generating reactive Te²⁻ ions; influences nucleation rate and particle growth dynamics [10] [15]. | Both |

| Polyvinyl Pyrrolidone (PVP) | Surfactant / Capping Agent | Adsorbs to specific crystal planes, reducing surface energy and promoting anisotropic growth into nanoplates or nanorods [14] [9]. | Hydrothermal |

| Ethylenediaminetetraacetic Acid (EDTA) | Chelating Agent / Reductant | Forms complexes with Bi³⁺ ions, controlling their release rate and favoring self-assembly into layered structures like nanosheets [15]. | Hydrothermal |

| Oleic Acid | Surfactant / Solubilizer | Binds to nanoparticle surfaces, preventing agglomeration and controlling particle size during rapid thermolysis reactions [4]. | Thermolysis |

| Tri-butyl Phosphine (TBP) | Complexing Agent / Solvent | Rapidly dissolves Te powder to form a reactive precursor, crucial for the fast kinetics of microwave-assisted synthesis [4]. | Thermolysis |

| Ethylene Glycol (EG) | Solvent / Reductant | Serves as a green reducing medium; its dielectric properties enable efficient microwave heating in thermolysis [9] [15]. | Both |

Mechanistic Insights and Pathway Analysis

The interplay of reductants, surfactants, and pH can be understood as a series of kinetic control points that steer the reaction along a pathway toward a specific nanostructure. The alkaline environment ensures the prerequisite chemical state (Te²⁻) is available. Reductants determine the rate at which metal ions are reduced, influencing nucleation density. Finally, surfactants adsorb to specific crystal faces, lowering their surface energy and dictating the direction of crystal growth, leading to the final morphology.

This mechanistic pathway, from precursor preparation to final nanostructure, is summarized in the diagram below.

Figure 2: The mechanistic pathway illustrating how pH, reductants, and surfactants collectively control the reaction kinetics and structural evolution during Bi₂Te₃ synthesis.

Formation of Surface States and Native Defects in Nanostructures

The functional properties of bismuth telluride (Bi₂Te₃) nanostructures—from thermoelectric efficiency to topological surface states—are profoundly influenced by their surface chemistry and native defect populations. These characteristics are, in turn, dictated by the synthesis methodology employed. Within materials science, two principal chemical routes have been established for fabricating Bi₂Te₃ nanostructures: hydrothermal synthesis and thermolysis. The hydrothermal approach typically involves a low-temperature, solution-based reaction in an aqueous or glycol medium, often within a sealed autoclave [9]. In contrast, thermolysis, particularly microwave-assisted thermolysis, relies on high-temperature decomposition of molecular precursors in a non-aqueous solvent to drive nanocrystal formation [4]. This guide provides a comparative analysis of these competing synthesis strategies, objectively evaluating their performance in tuning surface states and native defects, supported by experimental data on the resulting structural, magnetic, and thermoelectric properties.

Comparative Synthesis Protocols

Hydrothermal Synthesis Workflow

The hydrothermal method is characterized by its reliance on a closed system and relatively low reaction temperatures, fostering kinetic control over crystal growth and morphology.

- Primary Reagents: Ethylene Glycol (solvent), BiCl₃ (Bismuth source), TeO₂ (Tellurium source), NaOH (mineralizer), Polyvinyl Pyrrolidone (PVP, surfactant) [9].

- Detailed Protocol: TeO₂ (3.0 mmol), BiCl₃ (2.0 mmol), NaOH (20.0 mmol), and PVP (1.0 g) are dissolved in 100 mL of ethylene glycol under vigorous stirring. The homogeneous solution is transferred into a Teflon-lined stainless-steel autoclave. The sealed reactor is heated to and maintained at 180°C for 36 hours. After natural cooling to room temperature, the precipitate is collected via centrifugation, washed sequentially with deionized water, acetone, and ethanol, and finally dried at 60°C for 6 hours [9].

- Key Outcomes: This protocol yields uniform hexagonal Bi₂Te₃ nanosheets with lateral dimensions of 230–420 nm. The alkaline environment and presence of PVP are critical for directing the plate-like morphology [9].

Microwave-Assisted Thermolysis Workflow

Microwave-assisted thermolysis is a high-throughput, energy-efficient technique that utilizes microwave irradiation for rapid, volumetric heating, enabling precise control over nucleation and growth.

- Primary Reagents: 1-Octadecene (ODE, high-boiling solvent), Oleic acid (surfactant), BiCl₃ or SbCl₃ (metal source), Te powder (Tellurium source), Tri-butyl phosphine (TBP, complexing agent) [4].

- Detailed Protocol: Te powder is first complexed with TBP (6 mL) by heating to 220°C until fully dissolved. In a separate vial, BiCl₃ is dissolved in a mixture of oleic acid and ODE. The Te-TBP complex is then injected into the Bi-precursor solution. The final mixture is subjected to microwave irradiation (1800 W) with a rapid ramp to 220°C, held for a short dwell time of 2 to 4 minutes. The resulting nanocrystals are purified by precipitation with acetone or isopropanol [4].

- Key Outcomes: This method produces crystalline Bi₂Te₃ and Sb₂Te₃ nanopowders with defined local atomic structures, suitable for subsequent consolidation into bulk pellets via spark plasma sintering [4].

Direct Comparison of Synthesis Outcomes

The table below summarizes the core characteristics and resulting material properties from these two synthesis protocols.

Table 1: Objective Comparison of Hydrothermal and Thermolysis Synthesis Methods for Bi₂Te₃

| Aspect | Hydrothermal Synthesis | Microwave-Assisted Thermolysis |

|---|---|---|

| Synthesis Conditions | Aqueous/Glycol solvent, ~180°C, ~36 hours [9] | Organic solvent (ODE), ~220°C, ~2-4 minutes [4] |

| Energy & Time Input | Low heating rate, long duration (Energy- and time-intensive) | Instantaneous volumetric heating, ultra-fast reaction (Energy- and time-efficient) [4] |

| Primary Morphology | Hexagonal nanosheets (230-420 nm) [9] | Isotropic nanoparticles (specific size not listed) |

| Key Defects Formed | Likely vacancy-dominated (inferred from method) | Engineered antisite defects (BiTe and TeBi) possible [16] |

| Scalability | Batch processing, limited by autoclave volume | Highly scalable and reproducible [4] |

| Resulting Properties | Standard thermoelectric performance (S: -90 to -113 µVK⁻¹) [9] | High thermoelectric performance (ZT: 0.7-0.9) [4]; Can induce ferromagnetism [17] |

Defect Engineering and Functional Properties

Native Defects and Their Formation

The type and population of native defects are directly influenced by the synthesis thermodynamics and kinetics.

- Antisite Defects (BiTe and TeBi): These defects, where a Bi atom occupies a Te site or vice versa, are crucial for material properties. They predominantly form under conditions close to stoichiometry, which are more readily achieved in the high-temperature, controlled environment of thermolysis. The formation energy for these antisites is approximately 0.63 eV in Bi₂Te₃, making them favorable [16] [18]. Their coexistence is a key factor enabling exceptional plasticity in bulk crystals [16].

- Vacancies: Tellurium vacancies (VTe) are common native defects that act as n-type dopants. Their formation is often associated with deviations from stoichiometry, which can occur in both methods but may be more prevalent in hydrothermal synthesis due to the complex solution chemistry and lower temperature, which can hinder perfect stoichiometric control [19].

- Defects in Related Compounds: For comparison, in Bi₂Se₃, the formation energy for antisite defects is much higher (~1.32 eV), making them difficult to form. In Sb₂Te₃, achieving a balance of SbTe and TeSb antisites is challenging as it requires extreme Te-rich conditions, which are difficult to realize experimentally. This explains the poor plasticity and highly regular atomic structures observed in these related compounds [16] [18].

Impact on Material Performance

The specific defect profile engineered during synthesis directly dictates the functional performance of the nanostructures.

- Mechanical Plasticity: The coexistence of substantial BiTe and TeBi antisite defects is the primary source of the exceptional plasticity (>10% bending strain) observed in Bi₂Te₃ crystals. These defects agglomerate and interact to create high-density, diverse microstructures (ripplocations, dislocations) that dissipate mechanical stress, preventing crack propagation. Synthesis methods that favor these antisites (like thermolysis) are therefore key to producing flexible thermoelectric materials [16] [18].

- Thermoelectric Performance: Defects are central to optimizing the thermoelectric figure of merit, ZT. Point defects and grain boundaries effectively scatter phonons, thereby reducing lattice thermal conductivity. The high ZT values of 0.7 for n-type Bi₂Te₃ and 0.9 for p-type Sb₂Te₃ reported for thermolysis-synthesized and spark-plasma-sintered materials are a direct result of this defect-mediated phonon engineering [4].

- Magnetic Properties: Intrinsic point defects can introduce magnetic moments. Experimental studies on exfoliated and nanostructured Bi₂Te₃ have measured a ferromagnetic signal at room temperature. Density functional theory (DFT) simulations attribute this magnetism to the presence of vacancies and antisites, demonstrating that defect engineering via synthesis can open pathways to spintronic applications without external magnetic dopants [17].

The Scientist's Toolkit

Table 2: Essential Research Reagents and Their Functions

| Reagent | Function in Synthesis |

|---|---|

| Ethylene Glycol | Green solvent for hydrothermal synthesis; reduces environmental impact [9]. |

| 1-Octadecene (ODE) | High-boiling-point non-polar solvent for thermolysis; enables high-temperature reactions [4]. |

| Oleic Acid | Surfactant in thermolysis; binds to nanoparticle surfaces to control growth and prevent aggregation [4]. |

| Polyvinylpyrrolidone (PVP) | Structure-directing agent in hydrothermal synthesis; critical for achieving plate-like morphologies [9]. |

| Tri-butyl Phosphine (TBP) | Complexing agent for Tellurium powder; facilitates its dissolution and reaction at lower temperatures [4]. |

| Sodium Hydroxide (NaOH) | Mineralizer in hydrothermal synthesis; creates an alkaline environment that influences reaction kinetics and product purity [9]. |

Synthesis Workflow and Defect Pathways

The following diagram illustrates the two synthetic pathways and the distinct defect landscapes they create, which ultimately lead to different functional properties.

Figure 1: Synthesis pathways and defect-property relationships for hydrothermal and thermolysis methods.

Protocols for Hydrothermal and Thermolysis Synthesis of Bi₂Te₃ Nanostructures

Within the ongoing research on synthesizing bismuth telluride (Bi₂Te₃), a benchmark thermoelectric material, the hydrothermal method stands out for its simplicity, cost-effectiveness, and ability to produce nanostructures with tailored morphologies [6]. This guide objectively compares standard hydrothermal protocols for synthesizing Bi₂Te₃, detailing specific precursors, temperature, duration, and other critical parameters that dictate the final product's characteristics. The comparative analysis presented herein, framed within a broader thesis on Bi₂Te³ synthesis, provides researchers with a consolidated reference of experimental data to inform their material design strategies.

Comparative Analysis of Standard Hydrothermal Protocols

The table below summarizes the key parameters and outcomes from various standardized hydrothermal syntheses of Bi₂Te₃ as reported in recent literature.

Table 1: Comparison of Standard Hydrothermal Protocols for Bi₂Te₃ Synthesis

| Protocol Feature | Protocol A (Nanotubes) | Protocol B (Hexagonal Nanosheets) | Protocol C (Spherical Nanoparticles) | Protocol D (Morphology-Tuned) |

|---|---|---|---|---|

| Bismuth Precursor | BiCl₃ [20] | BiCl₃ [9] | Information Missing | BiCl₃ [6] |

| Tellurium Precursor | Na₂TeO₃ [20] | TeO₂ [9] | Information Missing | Te powder [6] |

| Reducing Agent | NaBH₄ [20] | Not Specified (Ethylene Glycol solvent) | Information Missing | NaBH₄ [6] |

| Surfactant | EDTA, PVP, SDS, or CTAB [20] | PVP [9] | Information Missing | EDTA-2Na [6] |

| Solvent | De-ionized water [20] | Ethylene Glycol [9] | Information Missing | De-ionized water [6] |

| Temperature (°C) | 180 [20] | 180 [9] | Information Missing | Varied (pH-dependent) [6] |

| Duration (Hours) | 48 [20] | 36 [9] | Information Missing | Information Missing |

| Key Alkaline Additive | NaOH (0.2-0.4 g) [20] | NaOH (20.0 mmol) [9] | Information Missing | KOH (for pH adjustment) [6] |

| Primary Morphology | Nanotubes [20] | Hexagonal Nanosheets (230-420 nm) [9] | Spherical Nanoparticles (~43 nm) [13] | Nanoplates, Nanoflowers, Nanotubes (pH-dependent) [6] |

| Reported Bandgap | Not Reported | Not Reported | 0.9 eV [13] | Not Reported |

Detailed Experimental Protocols

Protocol for Bi₂Te₃ Nanotubes

A representative hydrothermal procedure for synthesizing Bi₂Te₃ nanotubes is as follows [20]:

- Precursor Preparation: 1 mmol of BiCl₃ and 1.5 mmol of Na₂TeO₃ were dissolved in de-ionized water within a 50 mL Teflon-lined autoclave, filling it to 80% capacity.

- Additives: NaOH (0.2–0.4 g) and NaBH₄ (0.2–0.4 g) were added. A surfactant, such as EDTA, PVP, SDS, or CTAB (2 mmol), was introduced to influence morphology.

- Pre-Reaction Treatment: The autoclave was agitated in an ultrasonic generator at room temperature for 30 minutes before the main reaction.

- Hydrothermal Reaction: The autoclave was sealed and heated at 180°C for 48 hours, then allowed to cool to room temperature naturally.

- Product Isolation: The final product was collected, washed with de-ionized water and absolute ethanol, and dried in a vacuum at 60°C for 4 hours [20].

Protocol for Bi₂Te₃ Hexagonal Nanosheets

A "green" hydrothermal synthesis for producing hexagonal Bi₂Te₃ nanosheets uses ethylene glycol as a solvent [9]:

- Reaction Mixture: TeO₂ (3.0 mmol), BiCl₃ (2.0 mmol), NaOH (20.0 mmol), and the surfactant PVP (1.0 g) were dissolved in 100 mL of ethylene glycol.

- Hydrothermal Reaction: The mixture was transferred to a reaction kettle and heated at 180°C for 36 hours.

- Post-Processing: After cooling, the products were separated by centrifugation, washed sequentially with de-ionized water, acetone, and anhydrous ethanol, and finally dried at 60°C for 6 hours [9].

The Critical Role of pH in Morphology

The pH of the reaction solution is a profound tuning parameter. A comprehensive study systematically adjusted pH using HCl and KOH, leading to distinct outcomes [6]:

- Strongly Acidic (pH < 1): The reduction reaction is incomplete, resulting in a final product containing elemental Bi and Te impurities instead of pure Bi₂Te₃.

- Weakly Acidic to Near-Neutral (pH = 1 to 5): Rhombohedral Bi₂Te₃ is formed, but often with minor impurities.

- Alkaline Conditions (pH > 9): High-purity, single-phase rhombohedral Bi₂Te₃ is achieved. The specific morphology (nanoplates, nanoflowers, or nanotubes) is also determined by the pH level within this alkaline range, governed by crystal growth mechanisms like Ostwald ripening and oriented attachment [6].

Workflow Diagram of Hydrothermal Synthesis

The following diagram illustrates the general workflow and critical decision points in a standard hydrothermal synthesis of Bi₂Te₃, integrating the parameters discussed above.

Diagram Title: Hydrothermal Synthesis Workflow and Morphology Control

The Scientist's Toolkit: Essential Research Reagents

The following table lists key reagents and their functions in a standard Bi₂Te₃ hydrothermal synthesis, serving as a quick reference for experimental design.

Table 2: Essential Reagents for Bi₂Te₃ Hydrothermal Synthesis

| Reagent Name | Function in Synthesis | Specific Examples |

|---|---|---|

| Bismuth Precursor | Provides the Bi³⁺ source for crystal formation. | BiCl₃ [20] [9] [6] |

| Tellurium Precursor | Provides the Te source. Choice impacts reaction pathway. | Na₂TeO₃ [20], Te powder [6], TeO₂ [9] |

| Reducing Agent | Reduces the metallic precursors to their elemental states for alloying. | NaBH₄ [20] [6] |

| Surfactant / Capping Agent | Controls morphology by adsorbing to specific crystal faces, directing growth. | PVP [9], EDTA [20] [6] |

| Alkaline Agent | Creates a basic environment crucial for forming pure Bi₂Te₃ and influences morphology. | NaOH [20] [9], KOH [6] |

| Solvent | The reaction medium. | De-ionized Water [20] [6], Ethylene Glycol [9] |

{}

{: style="color:#5F6368; font-size: 14px;"} This guide is part of a broader thesis on the comparative surface chemistry of hydrothermal and thermolysis routes for synthesizing bismuth telluride (Bi₂Te₃), a key thermoelectric material.

Microwave-Assisted Thermolysis: A Rapid, High-Throughput Approach

The synthesis of advanced inorganic materials, such as thermoelectric bismuth telluride (Bi₂Te₃), has long been constrained by time-consuming and energy-intensive processes. Microwave-assisted thermolysis has emerged as a rapid, high-throughput alternative to conventional methods like hydrothermal synthesis. This guide provides an objective comparison of these techniques, focusing on their underlying principles, experimental outcomes, and performance data. By presenting detailed protocols and synthesized quantitative results, we aim to equip researchers with the information necessary to select the optimal synthetic route for their specific applications, particularly in the development of high-performance thermoelectric materials.

The pursuit of nanomaterials with precise structural and functional properties necessitates advanced synthesis techniques. For thermoelectric materials like Bi₂Te₃, the synthetic pathway directly influences critical characteristics such as crystallinity, particle morphology, and ultimately, the figure-of-merit (ZT). This section introduces the two primary solution-based chemical methods compared in this guide.

Microwave-Assisted Thermolysis: This is a solution-chemical route where precursors are dissolved in a solvent and heated rapidly and uniformly using microwave dielectric heating [21]. The "thermolysis" refers to the decomposition of precursors at elevated temperatures to form the desired product. Energy transfer occurs through direct interaction of microwaves with molecular dipoles in the reaction mixture, leading to volumetric "in-core" heating that is fundamentally different from conventional conduction heating [21]. This method is celebrated for its dramatic reduction in reaction time and high energy efficiency.

Hydrothermal Synthesis: This conventional method involves conducting reactions in a sealed vessel (autoclave) at high temperature and pressure using water or another solvent as the medium. The process typically relies on conventional conductive heating, where thermal energy transfers from the vessel walls to the reaction mixture, often resulting in steep temperature gradients and longer reaction times, typically ranging from several hours to days [22] [14].

The core difference lies in the heating mechanism: microwave thermolysis offers internal, molecular-level heating, while hydrothermal synthesis depends on external, conduction-based heating. This distinction has profound implications for the synthesis kinetics, product quality, and scalability.

Comparative Performance Data

The fundamental differences between microwave-assisted thermolysis and hydrothermal synthesis lead to distinct experimental outcomes. The table below summarizes a direct comparison of their performance in synthesizing Bi₂Te₃-based thermoelectric materials, based on published experimental data.

Table 1: Direct comparison of microwave-assisted thermolysis and hydrothermal synthesis for Bi₂Te₃-based materials.

| Performance Metric | Microwave-Assisted Thermolysis | Hydrothermal Synthesis |

|---|---|---|

| Typical Reaction Time | 2 minutes to 4 minutes [23] [4] | 3 to 24 hours [22] [14] |

| Reaction Temperature | ~220 °C [4] | ~150-200 °C [22] |

| Key Features | Energy-efficient volumetric heating; rapid kinetics [21] | Uses various reductants/surfactants to control morphology [14] |

| Crystallinity & Phase Purity | High crystallinity and phase purity [24] | High crystallinity, but may require ultrasonication assistance [22] |

| Common Morphology | Hexagonal platelets [24] | Nanorods, low-dimensional nanostructures [22] [14] |

| Achieved ZT (n-type Bi₂Te₃) | 0.7 to 1.04 [23] [24] | Information not specified in search results |

| Scalability & Throughput | High-throughput, scalable, minimal environmental impact [23] | Batch-to-batch variations, less scalable [23] |

The data demonstrates that microwave-assisted thermolysis offers unparalleled speed and energy efficiency. The significantly shorter reaction times—from hours to minutes—directly translate to higher throughput and lower energy consumption per batch [24]. Furthermore, materials produced via this route consistently show high crystallinity and phase purity, which are critical for achieving superior thermoelectric performance, as evidenced by the high ZT values.

Experimental Protocols

To ensure reproducibility and provide a clear technical foundation, this section outlines detailed experimental protocols for the microwave-assisted thermolysis of Bi₂Te₃ and Sb₂Te₃, as reported in recent literature.

Detailed Protocol: Microwave-Assisted Thermolysis of Bi₂Te₃/Sb₂Te₃

The following procedure, adapted from a 2025 study, describes a high-yield synthesis of these thermoelectric materials [23] [4].

3.1.1 Research Reagent Solutions

Table 2: Essential reagents and their functions in the microwave-assisted thermolysis synthesis.

| Reagent | Function in the Synthesis |

|---|---|

| Bismuth Chloride (BiCl₃) / Antimony Chloride (SbCl₃) | Metal precursor providing Bi³⁺ or Sb³⁺ ions [4] |

| Tellurium (Te) Powder | Chalcogen source providing Te atoms [4] |

| Tri-butyl Phosphine (TBP) | Complexing and reducing agent for Tellurium powder [4] |

| Oleic Acid | Surfactant and solvent for the metal precursor [4] |

| 1-Octadecene (ODE) | Non-polar solvent with high boiling point [4] |

| Thioglycolic Acid (TGA) | Potential capping agent to control particle growth |

3.1.2 Step-by-Step Workflow

- Tellurium Complex Preparation: Dissolve a stoichiometric amount of Tellurium powder in 6 mL of Tri-butyl Phosphine (TBP) by heating the mixture to 220 °C under constant stirring until a clear solution is obtained. This step uses microwave power of 400 W [4].

- Metal Precursor Solution: In a separate vial, dissolve a stoichiometric amount of Bismuth Chloride (BiCl₃) or Antimony Chloride (SbCl₃) in Oleic acid under continuous stirring for 30 minutes. The molar ratio of Metal (Bi/Sb) to Te should be maintained at 2:3 [4].

- Reaction Mixture: Transfer the metal precursor solution to a 100 mL microwave reaction vessel. Add 1-Octadecene (ODE) as the primary solvent. Subsequently, inject the prepared Tellurium-TBP complex into this vessel and mix thoroughly [4].

- Microwave Reaction: Heat the mixture using a high-power microwave reactor (e.g., Milestone flexiWAVE). The typical reaction parameters are a temperature of 220 °C, with a ramp time of 4 minutes and a very short dwell (hold) time of 2 minutes [4].

- Product Isolation: After the reaction, cool the vessel naturally. Precipitate the synthesized nanopowders by adding acetone or isopropanol, then separate them via centrifugation. Wash the pellets multiple times with fresh solvent to remove any residual organics and dry them to obtain the final powder [4].

- Consolidation (for property measurement): To fabricate solid pellets for thermoelectric testing, consolidate the as-made powders using Spark Plasma Sintering (SPS). A typical SPS protocol involves sintering at 400 °C under a pressure of 70 MPa, with a heating rate of 30 °C/min and a holding time of 5 minutes [23] [4].

Diagram 1: Workflow for microwave thermolysis synthesis.

Key Aspects of Hydrothermal Synthesis

For comparative purposes, a standard protocol for the hydrothermal synthesis of doped Bi₂Te₃ is outlined below, based on earlier research [22].

- Precursor Preparation: Dissolve bismuth and tellurium precursors in an alkaline aqueous solution. The solution may include dopants (e.g., Ag, Sb, Sn ions) and a reducing agent such as sodium borohydride (NaBH₄).

- Reaction Setup: Transfer the solution to a Teflon-lined stainless-steel autoclave, typically filling it to about 80% of its capacity.

- Hydrothermal Reaction: Seal the autoclave and heat it in a conventional oven at a temperature of around 200 °C for a prolonged period, often 3 to 24 hours [22] [14].

- Product Isolation: After the reaction, allow the autoclave to cool to room temperature. The resulting solid product is collected by filtration or centrifugation, followed by washing and drying.

Analysis of Synthesis Pathways

The experimental data reveals a clear divergence in the efficiency and output of the two methods, rooted in their fundamental physical principles.

Heating Mechanism and Efficiency: The superiority of microwave-assisted thermolysis in reaction time stems from its heating mechanism. Microwaves interact directly with solvent and reagent molecules (dipoles and ions), causing them to rotate and generate heat volumetrically throughout the entire reaction mixture simultaneously. This "in-core" heating eliminates the thermal gradients found in conductive heating, allowing for extremely rapid and uniform temperature rise [21]. In contrast, hydrothermal synthesis relies on conduction from the walls of the autoclave, a slower process that can lead to localized heating and inconsistent reaction conditions.

Impact on Material Properties: The rapid, uniform heating of microwave thermolysis promotes homogeneous nucleation and controlled growth, resulting in materials with high crystallinity and phase purity without the need for prolonged heating [24]. This method has been shown to produce materials, particularly n-type Bi₂Te₃, with a high thermoelectric figure-of-merit (ZT up to 1.04) [24]. Hydrothermal synthesis, while capable of producing various nanostructures like nanorods through the use of surfactants [14], is more susceptible to batch-to-batch variations and often requires post-synthesis treatments, such as ultrasonication, to achieve desired nanostructures [22].

This comparative analysis objectively demonstrates that microwave-assisted thermolysis holds a significant advantage over traditional hydrothermal synthesis for the rapid, high-throughput production of high-performance thermoelectric materials like Bi₂Te₃. Its unparalleled speed, energy efficiency, and ability to produce materials with excellent crystallinity and competitive ZT values make it a compelling choice for modern materials research and development.

Within the broader thesis of comparative surface chemistry, this guide confirms that the synthesis pathway is a critical determinant of final material properties. While hydrothermal methods remain useful for exploring specific nanostructured morphologies, microwave-assisted thermolysis represents a paradigm shift towards faster, more efficient, and scalable nanomaterial synthesis. Future research will likely focus on optimizing microwave reactor designs, exploring a wider range of solvent and precursor systems, and further scaling up this promising technology for industrial application.

The Impact of Surfactants and Capping Agents on Morphology

In the synthesis of functional nanomaterials, surface chemistry plays a decisive role in determining morphological outcomes and final material properties. Within the context of comparative synthesis routes for bismuth telluride (Bi₂Te₃)—a material of significant thermoelectric and topological importance—the choice of surfactants and capping agents directly dictates the architecture of the resulting nanostructures. This guide objectively compares the performance of different surface-modifying agents in the hydrothermal synthesis of Bi₂Te₃ against the thermolysis route, providing researchers with experimental data and protocols to inform their synthetic strategies. The controlled application of these agents enables precise manipulation of nucleation and growth kinetics, facilitating the formation of nanostructures with tailored dimensions and enhanced performance characteristics for applications ranging from thermoelectric energy conversion to photodetection.

Fundamental Mechanisms of Capping Agents

Capping agents are amphiphilic molecules consisting of a polar head group and a non-polar hydrocarbon tail. In colloidal synthesis, they function as stabilizers that adsorb to the surfaces of growing nanoparticles, thereby inhibiting over-growth and preventing aggregation or coagulation [25]. Their mechanism of action stems from steric hindrance, where the bulky organic chains of the capping ligands create a physical barrier between individual nanoparticles [25].

The specific interaction between the capping agent and crystallographic facets governs morphological evolution. The polar head group coordinates with metal atoms on the nanoparticle surface, while the non-polar tail interacts with the surrounding solvent medium [25]. This differential binding affinity across crystal faces leads to anisotropic growth, where certain crystallographic directions are favored over others. For instance, in the hydrothermal synthesis of Bi₂Te₃, selective capping of specific facets can promote the formation of two-dimensional nanosheets over other potential morphologies [9].

Table 1: Common Capping Agents and Their Primary Functions in Nanomaterial Synthesis

| Capping Agent | Chemical Classification | Primary Function | Compatibility |

|---|---|---|---|

| Polyvinylpyrrolidone (PVP) | Polymer | Shape control, stabilization in polar solvents | Hydrothermal, Solvothermal |

| Polyethylene Glycol (PEG) | Polymer | Biocompatibility enhancement, dispersion stability | Aqueous phase synthesis |

| Bovine Serum Albumin (BSA) | Protein | Bio-conjugation, green synthesis | Biocompatible applications |

| Ethylenediamine tetraacetic acid (EDTA) | Chelating agent | Morphology and size control via ion complexation | Aqueous synthesis |

Comparative Analysis: Hydrothermal vs. Thermolysis Synthesis

Hydrothermal Synthesis with Surfactant Control

The hydrothermal method has proven to be a feasible approach for manipulating the morphology and size of Bi₂Te₃ nanostructures, offering advantages including low equipment requirements, cost-effectiveness, and moderate synthesis temperatures [9]. In a typical "green" hydrothermal synthesis, Bi₂Te₃ hexagonal nanosheets with dimensions of 230–420 nm have been successfully fabricated using ethylene glycol as a solvent and polyvinylpyrrolidone (PVP) as a surfactant [9].

The presence of PVP is critical for plate-like morphology, as it selectively binds to certain crystal facets, directing two-dimensional growth. Additional parameters influencing morphological evolution include reaction temperature, alkaline environment (controlled by NaOH concentration), and reaction duration [9]. Through systematic optimization of these parameters, researchers achieved Bi₂Te₃ single crystals with well-defined hexagonal symmetry.

Table 2: Impact of Synthesis Parameters on Bi₂Te₃ Morphology in Hydrothermal Synthesis

| Synthesis Parameter | Impact on Morphology | Optimal Condition for Nanosheets |

|---|---|---|

| Surfactant Type | Determines crystal habit and growth direction | PVP (1.0 g in 100 mL EG) |

| Reaction Temperature | Affects nucleation rate and crystal quality | 180 °C |

| Alkaline Environment (NaOH) | Influences reaction kinetics and phase purity | 20.0 mmol |

| Reaction Duration | Controls crystal size and completeness of growth | 36 hours |

The electrical transport properties of hot-pressed pellets derived from these nanosheets demonstrate the functional efficacy of the morphology-controlled synthesis, with electrical conductivity (σ) ranging from ( 18.5 \times 10^3 ) to ( 28.69 \times 10^3 ) S·m(^{-1}) and Seebeck coefficient (S) between -90.4 to -113.3 µV·K(^{-1}) over a temperature range of 300–550 K [9].

Different surfactant systems yield distinct morphological outcomes. Research comparing various surfactants in Bi₂Te₃ nanopowder synthesis revealed that flower-like nanosheets obtained with specific surfactants produced bulk pellets with superior thermoelectric properties, achieving a figure of merit (ZT) of approximately 1.16 after hot pressing [26]. This enhancement stemmed from an optimal microstructure that simultaneously lowered electrical resistivity, increased the Seebeck coefficient, and reduced thermal conductivity.

Thermolysis Synthesis Approach

While hydrothermal methods benefit from precise surfactant-mediated morphological control, thermolysis approaches typically involve high-temperature decomposition of molecular precursors in organic solvents. This method often employs metal-organic compounds or coordination complexes as precursors, which are heated in high-boiling-point solvents in the presence of surfactants to control nucleation and growth.

In thermolysis, the thermal energy supplied drives the decomposition of precursors and subsequent nanocrystal formation, with surfactants such as oleic acid and oleylamine frequently employed to regulate growth and prevent aggregation. The coordinating strength of these surfactant molecules with specific crystal facets becomes temperature-dependent, creating opportunities for morphology control through precise temperature programming.

However, comparative experimental data specifically linking surfactant type to Bi₂Te₃ morphology in thermolysis reactions is less extensively documented in the available literature compared to hydrothermal approaches. The higher temperature conditions often lead to faster reaction kinetics, which can complicate real-time morphological control but may offer advantages in crystallinity and production throughput.

Experimental Protocols for Morphology-Controlled Synthesis

Hydrothermal Synthesis of Bi₂Te₃ Hexagonal Nanosheets

Materials and Reagents:

- Bismuth chloride (BiCl₃, 2.0 mmol, AR grade)

- Tellurium dioxide (TeO₂, 3.0 mmol, AR grade)

- Sodium hydroxide (NaOH, 20.0 mmol, AR grade)

- Polyvinylpyrrolidone (PVP K-30, 1.0 g, AR grade)

- Ethylene glycol (100.00 mL, AR grade)

- Deionized water, acetone, and anhydrous ethanol for washing

Procedure:

- Precursor Preparation: Dissolve TeO₂, BiCl₃, NaOH, and PVP sequentially in ethylene glycol with continuous stirring until a homogeneous solution is obtained.

- Reaction Setup: Transfer the solution to a Teflon-lined stainless-steel autoclave, seal securely, and place in a preheated oven.

- Hydrothermal Reaction: Maintain the autoclave at 180 °C for 36 hours to allow complete crystal growth.

- Product Recovery: After natural cooling to room temperature, separate the products by centrifugation.

- Purification: Wash sequentially with deionized water, acetone, and anhydrous ethanol to remove residual reactants and solvents.

- Drying: Dry the purified product at 60 °C for 6 hours in a vacuum oven [9].

Characterization:

- Structural Analysis: X-ray powder diffraction (XRD) with Cu Kα radiation to confirm phase purity and crystallinity (JCPDS: 15-0863).

- Morphological Assessment: Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) to verify hexagonal nanosheet morphology and determine dimensions.

- Elemental Composition: Energy-dispersive X-ray (EDX) spectroscopy for stoichiometric confirmation.

- Transport Properties: For thermoelectric applications, measure electrical conductivity and Seebeck coefficient using a thermoelectric test system (300–550 K range) [9].

Surfactant Performance Comparison Protocol

To objectively compare surfactant performance in morphology control:

- Standardized Synthesis: Maintain identical precursor concentrations, temperature (180 °C), and reaction duration (36 hours) across all experiments.

- Surfactant Variation: Test different surfactant types (PVP, CTAB, SDS) at equivalent molar concentrations.

- Morphological Analysis: Quantify morphological outcomes using SEM image analysis, recording:

- Average particle size (nm)

- Aspect ratio

- Shape uniformity

- Degree of aggregation

- Performance Correlation: For thermoelectric applications, process powders into bulk pellets via spark plasma sintering under identical conditions (e.g., 688 K, 60 MPa, 15 min) and measure thermoelectric properties [9] [26].

Research Reagent Solutions Toolkit

Table 3: Essential Research Reagents for Surfactant-Mediated Bi₂Te₃ Synthesis

| Reagent | Function | Application Notes |

|---|---|---|

| Polyvinylpyrrolidone (PVP) | Structure-directing agent; promotes 2D growth | Critical for hexagonal nanosheet morphology; molecular weight affects binding strength |

| Ethylene Glycol | Solvent and mild reducing agent | Green synthesis alternative; facilitates PVP dissolution |

| Sodium Hydroxide (NaOH) | Mineralizer; creates alkaline environment | Essential for single crystal formation; concentration affects reaction kinetics |

| Bismuth Chloride (BiCl₃) | Bismuth source | Hygroscopic; requires anhydrous handling |

| Tellurium Dioxide (TeO₂) | Tellurium source | Moderate toxicity; requires appropriate safety measures |

| Sodium Borohydride (NaBH₄) | Alternative reducing agent | Strong reducing agent; not typically required in green synthesis approaches |

Visualization of Experimental Workflows and Mechanisms

The following diagrams illustrate the key experimental workflows and mechanistic relationships in surfactant-controlled synthesis of Bi₂Te₃.

The strategic application of surfactants and capping agents provides powerful morphological control in Bi₂Te₃ synthesis, with significant differences observed between hydrothermal and thermolysis approaches. The hydrothermal method, particularly when employing PVP as a structure-directing agent, enables precise fabrication of two-dimensional hexagonal nanosheets with superior thermoelectric performance. The available experimental data demonstrates that surfactant selection directly correlates with morphological outcomes, which in turn dictates functional properties in applications ranging from thermoelectric generators to photodetectors.

While hydrothermal synthesis offers superior morphological control through surfactant mediation, thermolysis may provide advantages in crystallinity and scalability. Researchers should select their surface chemistry strategy based on target morphology, desired properties, and synthesis constraints, with the experimental protocols and comparative data provided herein serving as a foundation for informed decision-making in materials design.

The development of thermoelectric (TE) materials, capable of directly converting heat into electrical energy, represents a crucial frontier in sustainable energy technologies. Among these materials, bismuth telluride (Bi₂Te₃) and its alloys stand out as the most efficient TE materials for near room-temperature applications, finding use in power generation, cooling systems, and wearable devices [9]. However, traditional synthesis methods often involve toxic reagents, hazardous solvents, and energy-intensive processes, creating a significant environmental burden. Green synthesis approaches have therefore emerged as essential strategies for reducing or eliminating the use of hazardous substances in the production of functional nanomaterials [9]. The principles of green chemistry emphasize the use of environmentally benign reagents and solvents, minimization of waste, and enhanced energy efficiency [15]. Within this framework, water (with its high dielectric constant) and ethylene glycol (EG) (a low-toxicity, renewable polyol solvent) have become cornerstone reaction media for sustainable nanomaterial synthesis. This review comprehensively compares these two green synthesis pathways for Bi₂Te₃, examining their respective experimental protocols, morphological outcomes, surface chemistry characteristics, and ultimate thermoelectric performance to guide researchers in selecting optimal synthesis strategies.

Experimental Protocols: Water-Based Hydrothermal vs. EG-Based Polyol Methods

Hydrothermal Synthesis in Aqueous Media