Start-Up Cycles for Stable SPR: A Practical Guide to Minimizing Baseline Drift

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for using start-up cycles to minimize baseline drift in Surface Plasmon Resonance (SPR) experiments.

Start-Up Cycles for Stable SPR: A Practical Guide to Minimizing Baseline Drift

Abstract

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for using start-up cycles to minimize baseline drift in Surface Plasmon Resonance (SPR) experiments. It covers the foundational causes of drift, outlines a step-by-step methodological approach for implementing start-up cycles, presents advanced troubleshooting and optimization strategies, and details validation techniques to ensure data integrity. By systematically addressing this common issue, the article enables the collection of high-quality, reliable kinetic and affinity data, which is crucial for robust biomolecular interaction analysis in drug discovery and basic research.

Understanding SPR Baseline Drift: Causes, Consequences, and the Start-Up Cycle Solution

In Surface Plasmon Resonance (SPR) analysis, the sensorgram provides a real-time, label-free measurement of biomolecular interactions, plotting the SPR response (in Resonance Units, RU) against time. A critical foundation for interpreting this data is a stable baseline, which represents the signal from the sensor surface when only running buffer flows over it, before analyte injection. Baseline drift is the gradual, often steady, increase or decrease of this signal when no specific binding should be occurring. It is a common phenomenon that, if unaddressed, can obscure the true binding signal, lead to inaccurate calculation of kinetic parameters (such as association rate, ( ka ), and dissociation rate, ( kd )), and ultimately compromise the validity of an experiment [1] [2].

This application note defines the problem of baseline drift within the context of academic and industrial drug development research. A particular focus is placed on the proactive strategy of using start-up cycles to minimize drift, a methodology that enhances data quality and operational efficiency by stabilizing the system before critical data collection begins [1].

Root Causes and Impacts of Baseline Drift

Primary Causes of Drift

Understanding the root causes of baseline drift is the first step in its mitigation. The issue typically originates from physical and chemical instabilities within the SPR system or experimental reagents.

- System and Surface Equilibration: The most frequent cause of drift is a sensor surface that has not reached full equilibrium with the running buffer. This is often observed directly after docking a new sensor chip or following the immobilization of a ligand, as the surface rehydrates and residual chemicals from the immobilization procedure are washed out [1] [3]. The sensor surface and the immobilized ligand itself can take time to adjust to the flow buffer.

- Buffer-Related Issues: Changes in running buffer, or the use of buffers that are not properly prepared, are a major source of drift. Buffers stored at 4°C can contain dissolved air that forms tiny bubbles upon warming, causing spikes and drift. Furthermore, failing to thoroughly prime the system after a buffer change causes the previous and new buffers to mix in the pump, creating a wavy baseline until the system is homogeneous [1] [4].

- Ligand and Surface Instability: Some immobilized ligands may be inherently unstable under the flow conditions. Additionally, inefficient regeneration of the surface between analyte injections can lead to a buildup of residual material, which gradually shifts the baseline over multiple cycles [5] [2].

- Temperature and Pressure Fluctuations: The SPR system is highly sensitive to environmental changes. Fluctuations in temperature can affect the refractive index of the buffer, while pressure changes, such as those from pump refill strokes, can cause small spikes and subsequent baseline shifts [6] [4].

Impact on Data Quality

Baseline drift is not merely a cosmetic issue; it has direct and significant consequences on data analysis.

- Kinetic Analysis Errors: The accurate fitting of binding curves to determine ( ka ) and ( kd ) relies on a stable starting point. An upward or downward drifting baseline can make a weak interaction appear stronger, or a fast-dissociating interaction seem more stable, leading to incorrect conclusions about the mechanism and affinity of the interaction.

- Compromised Affinity Measurements: The equilibrium dissociation constant (( KD )), a critical parameter in drug development for ranking lead compounds, is calculated from the ratio of the kinetic rates (( kd/ka )). Errors in these rates due to baseline drift directly translate into inaccurate ( KD ) values [6].

- Difficulty in Referencing: SPR data relies heavily on reference channel subtraction to remove non-specific effects. Significant and unequal drift between the active and reference channels can make proper referencing difficult, leaving residual drift in the processed sensorgram [7].

Table 1: Common Causes and Signs of Baseline Drift

| Category | Specific Cause | Observable Sign in Sensorgram |

|---|---|---|

| System Equilibration | Newly docked sensor chip | Steady, continuous drift after start-up |

| Post-immobilization surface | Drift that decreases slowly over time | |

| Buffer Issues | Improperly degassed buffer | Sudden spikes followed by drift |

| Buffer mismatch/change | Step-change ("jump") at injection start/end | |

| Surface Issues | Incomplete regeneration | Gradual upward drift over multiple cycles |

| Unstable ligand | Continuous drift throughout an experiment | |

| Instrument Issues | Pump refill strokes | Regular, sharp spikes at intervals |

| Temperature fluctuations | Slow, wave-like baseline oscillations |

Experimental Protocols for Diagnosing and Minimizing Drift

A systematic approach to experimental setup can effectively diagnose, minimize, and correct for baseline drift.

Protocol 1: System Preparation and Equilibration

Objective: To establish a stable, low-drift baseline before commencing the analyte injection experiment.

- Buffer Preparation: Prepare running buffer fresh daily. Filter through a 0.22 µm filter and degas thoroughly to remove dissolved air, which is a primary cause of spikes and drift. If required, add detergents (e.g., Tween-20) after the degassing step to prevent foam formation [1] [4].

- System Priming: After any buffer change or at the start of a new experiment, prime the instrument multiple times with the new running buffer. This ensures the fluidics system is completely purged of the previous solvent and is homogeneously filled with the experimental buffer [1].

- Initial Equilibration: Flow running buffer over the sensor surface at the experimental flow rate. Monitor the baseline in real-time. For a new or freshly immobilized chip, this may require 5–30 minutes, or in some cases, overnight equilibration to achieve a stable baseline (drift < 1-5 RU/min) [1] [3].

- Incorporate Start-Up Cycles: Program the experimental method to include at least three start-up cycles before the first analyte injection. These cycles should be identical to the experimental cycles but inject running buffer instead of analyte. If a regeneration step is used, it should also be included. These cycles "prime" the fluidics and the sensor surface, allowing the system to stabilize from any disturbances caused by the initial flow start or the first regeneration injections. Do not use these start-up cycles for data analysis or as blanks [1].

Protocol 2: Diagnostic Injection Test

Objective: To assess the instrument's performance and identify potential sources of drift or artifacts.

- Chip and Solution Setup: Use a clean, blank sensor chip (e.g., plain gold or dextran-coated). Prepare a test solution by adding 50 mM NaCl to your running buffer [4].

- Create a Dilution Series: Create a series of this test solution in running buffer, for example: 50, 25, 12.5, 6.3, 3.1, 1.6, 0.8, and 0 mM added NaCl.

- Execute Test Injections: Inject the solutions from the lowest to the highest concentration, ending with an injection of running buffer alone (0 mM). Use the same injection volume and flow rate planned for your real experiment.

- Analyze the Sensorgrams:

- Shape: The rise and fall of the sensorgram should be smooth and immediate.

- Steady-State: The signal during injection should be flat, without drift.

- Carry-over: The final buffer injection should show a flat line, indicating no carry-over from the previous salty injections [4].

This test provides a quantitative insight into how your system responds to changes in buffer composition and confirms the injection system is functioning correctly.

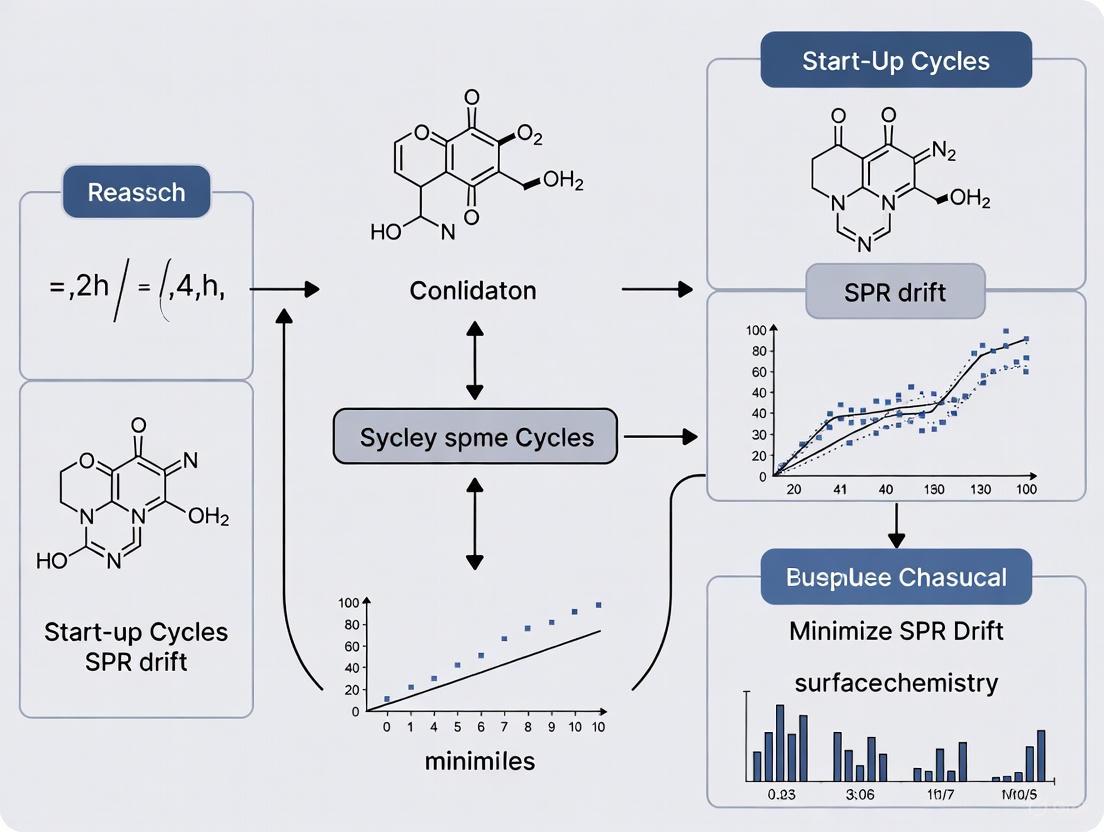

Diagram 1: System equilibration and startup workflow.

The Scientist's Toolkit: Essential Reagents and Materials

The following table lists key reagents and materials crucial for preventing and managing baseline drift in SPR experiments.

Table 2: Essential Research Reagent Solutions for Managing Baseline Drift

| Item | Function & Application | Key Consideration |

|---|---|---|

| High-Purity Buffers (e.g., PBS, HEPES) | Provides the continuous flow phase; maintains pH and ionic strength to preserve biomolecule activity. | Prepare fresh daily; 0.22 µm filter and degas before use to remove particulates and air [1] [5]. |

| Sensor Chips (e.g., CM5, NTA, SA) | The platform for ligand immobilization via various surface chemistries (dextran, nitrilotriacetic acid, streptavidin). | Select a chip with chemistry appropriate for your ligand to ensure stable immobilization and minimize non-specific binding [5]. |

| Degassing Unit | Integrated or standalone unit to remove dissolved gasses from buffers. | Essential for preventing air bubble formation in microfluidics, which cause spikes and drift [2] [4]. |

| Regeneration Solutions (e.g., Glycine-HCl, NaOH) | Removes bound analyte from the immobilized ligand to reset the surface for the next cycle. | Solution strength and exposure time must be optimized to fully regenerate without damaging ligand activity [6] [5]. |

| Detergents (e.g., Tween-20) | Additive to running buffer to reduce non-specific binding to the sensor chip surface. | Add after degassing to prevent foam formation [1]. |

| Size-Exclusion Columns | For buffer exchange of analyte samples into the running buffer. | Critical for minimizing bulk refractive index shifts when analyte stock is in a different buffer [4]. |

Data Processing and Referencing to Correct for Drift

Even with optimized protocols, some level of drift may remain. Data processing techniques are essential for its final correction.

Double Referencing: This is the gold-standard procedure for compensating for residual drift, bulk refractive index effects, and channel differences [1] [7].

- Step 1: Reference Channel Subtraction. Subtract the signal from a reference surface (a channel with no ligand or an irrelevant ligand) from the signal of the active ligand surface. This compensates for the majority of the bulk effect and system-wide drift.

- Step 2: Blank Injection Subtraction. Subtract the signal from injections of running buffer (blanks) collected over the active ligand surface. This corrects for any remaining differences between the reference and active channels, including surface-specific drift. For best results, blank cycles should be spaced evenly throughout the experiment [1] [7].

Baseline Alignment: During data processing, software tools can perform a baseline alignment. This adjustment sets the response level for a selected region (typically pre-injection) of all sensorgrams to the same zero level, removing slight baseline-level differences between runs [7].

Table 3: Data Processing Steps to Correct for Drift

| Processing Step | Description | Primary Function |

|---|---|---|

| Reference Subtraction | Active channel signal – Reference channel signal | Removes bulk refractive index change and non-specific binding common to both surfaces. |

| Blank Subtraction (Double Referencing) | Referenced signal – Blank injection signal | Corrects for baseline drift and differences specific to the active ligand surface. |

| Baseline Alignment | Software-based alignment of pre-injection baseline to a zero level | Normalizes the starting point of multiple sensorgrams for comparative analysis. |

Baseline drift in SPR sensorgrams is a multifactorial problem rooted in system instability, but it can be systematically managed. A successful strategy combines rigorous pre-experimental preparation—using fresh, degassed buffers and allowing for sufficient system equilibration—with the strategic implementation of start-up cycles to condition the sensor surface and fluidics. Furthermore, a well-designed experiment that incorporates regular blank injections enables the powerful data processing technique of double referencing to correct for any residual drift. By adopting these protocols, researchers can significantly enhance the quality and reliability of their SPR data, ensuring accurate determination of kinetic and affinity parameters critical to drug development.

Achieving a stable baseline is a foundational requirement for generating high-quality Surface Plasmon Resonance (SPR) data. Uncontrolled baseline drift directly compromises the accuracy of kinetic and affinity measurements, leading to erroneous results and wasted experimental time [1]. Within the broader context of optimizing start-up cycles to minimize SPR drift, three recurring culprits are consistently identified: surface equilibration issues, buffer changes, and flow start-up effects [1] [8]. This application note details the underlying mechanisms of these destabilizing factors and provides structured protocols and solutions to mitigate them, thereby enhancing the reliability of SPR research.

The Core Mechanisms of Baseline Drift

Surface Equilibration

Baseline drift is most frequently a sign of a non-equilibrated sensor surface [1]. Following sensor chip docking or ligand immobilization, the surface undergoes rehydration, and chemicals from the immobilization procedure are washed out. Furthermore, the immobilized ligand itself must adjust to the flow buffer conditions [1]. A surface that has not been fully equilibrated will produce a drifting baseline as it slowly reaches a state of stability, a process that can sometimes require flowing running buffer overnight for complete stabilization [1]. After immobilization, it is equally critical to subject the ligand surface to several cycles of analyte injection and regeneration to stabilize its binding performance, preventing drift and changing analyte binding in the initial experimental cycles [9].

Buffer Changes and Preparation

Altering the running buffer is another primary cause of baseline drift. Failing to prime the system thoroughly after a buffer change results in a "waviness pump stroke" effect as the previous and new buffers mix within the pump [1]. The preparation of the buffer itself is also crucial; buffers stored at 4°C contain more dissolved air, which can lead to air spikes in the sensorgram [1]. Proper buffer hygiene is paramount, and it is considered bad practice to add fresh buffer to old stock, as contaminants can grow in the old buffer and introduce disturbances [1].

Flow Start-Up

The initiation of fluid flow after a period of standstill is a common trigger for start-up drift [1]. Some sensor surfaces are inherently susceptible to flow changes, which manifests as a drift that levels out over 5–30 minutes [1]. This effect can also be seen as a "flow change" disturbance, where a change in flow rate causes a drift in the sensorgram [8]. The duration of this effect depends on the sensor type and the nature of the immobilized ligand [1] [8].

Table 1: Quantitative Drift Criteria and Targets

| Parameter | Target Value | Description & Implication |

|---|---|---|

| Baseline Drift Rate | < ± 0.3 RU/min [9] | Acceptable drift level for a well-equilibrated system. |

| Analyte Concentration Range | 0.1 - 10 times the KD [10] | Provides responses from 10–90% of Rmax for reliable analysis. |

| Equilibration Time Post Flow-Start | 5 - 30 minutes [1] [8] | Typical time for baseline to stabilize after initiating flow. |

Experimental Protocols for Drift Mitigation

Protocol: System Equilibration and Start-Up Cycles

This protocol is designed to stabilize the SPR system and sensor surface before analytical cycles begin, directly addressing surface and flow-start drift.

I. Objectives To minimize baseline drift resulting from surface rehydration, residual chemicals, and flow start-up by implementing a systematic equilibration and start-up procedure.

II. Materials

- Fresh running buffer, 0.22 µM filtered and degassed [1].

- Docked sensor chip (with or without immobilized ligand).

III. Procedure

- Buffer Priming: After any buffer change or at the start of a method, prime the system thoroughly to replace the liquid in the pumps and tubing completely [1] [9].

- Initial Equilibration: Flow running buffer at the experimental flow rate until a stable baseline is obtained. If drift persists after immobilization, it may be necessary to flow running buffer overnight [1].

- Start-Up Cycles: Incorporate at least three start-up cycles into the experimental method. These cycles should be identical to analytical cycles but inject running buffer instead of analyte. If a regeneration step is used, it should also be included [1].

- System Stabilization: These start-up cycles "prime" the surface, stabilizing it and removing the influence of initial regeneration cycles. Do not use these start-up cycles as blanks in the final analysis [1].

IV. Data Interpretation A successful protocol yields a baseline with a drift rate of < ± 0.3 RU/min [9]. The buffer injections in the start-up cycles should show low responses (< 5 RU) and a stable, non-wavy profile [9].

Protocol: Managing Buffer Changes and Bulk Effects

This protocol ensures that buffer changes do not introduce drift or bulk refractive index shifts that can interfere with binding data.

I. Objectives To execute a buffer change without introducing mixing-related drift or bulk effects, and to establish a system for effectively correcting for residual bulk shifts.

II. Materials

- Fresh running buffer, prepared daily, 0.22 µM filtered and degassed [1].

- A reference flow cell on the sensor chip that closely matches the active surface.

III. Procedure

- Buffer Preparation: Prepare 2 liters of buffer and 0.22 µM filter it. Store in a clean, sterile bottle at room temperature. Before use, transfer an aliquot to a new clean bottle and degas. Add detergents after filtering and degassing to avoid foam formation [1].

- System Priming: After changing the buffer bottle, always use the PRIME command to flush the system completely and prevent buffer mixing in the pumps [1] [8].

- Double Referencing Setup: Incorporate blank injections (running buffer only) spaced evenly throughout the experiment, at a rate of approximately one blank every five to six analyte cycles, ending with one [1].

- Data Processing: Perform double referencing during data analysis. First, subtract the response from the reference flow cell from the active flow cell. Second, subtract the averaged response from the blank injections [1].

The logical relationship between the common culprits, their consequences, and the recommended solutions is summarized in the workflow below.

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key reagents and materials essential for implementing the drift mitigation protocols described in this application note.

Table 2: Research Reagent Solutions for SPR Drift Mitigation

| Item | Function & Rationale | Protocol Specifics |

|---|---|---|

| 0.22 µM Filter | Removes particulate matter from buffers that can cause spikes and clog microfluidics [1]. | Use for filtering all running buffers before degassing. |

| Degassing Unit | Removes dissolved air to prevent the formation of air bubbles in the flow system, a common cause of spikes and drift [1] [8]. | Degas buffers after filtering and before adding detergents. |

| Appropriate Detergent (e.g., Tween-20) | Added to running buffer to reduce non-specific binding and minimize bulk effects [1] [10]. | Add after filtering and degassing to prevent foam formation [1]. |

| Reference Sensor Chip | Provides a surface for subtraction of refractive index bulk effects and instrument drift [1]. | Should closely match the active surface for effective double referencing. |

| Regeneration Solution (e.g., Glycine pH 1.5-2.5) | Removes bound analyte without damaging the ligand, allowing for surface re-use and stabilizing response between cycles [9] [10]. | Choose the mildest effective condition; scout conditions empirically. |

A deliberate and proactive approach to the initial phases of an SPR experiment is critical for success. By recognizing the common culprits of drift—surface non-equilibration, improper buffer handling, and flow start-up effects—and implementing the detailed protocols provided, researchers can achieve the stable baseline required for acquiring high-fidelity binding data. Integrating these practices, particularly the use of start-up cycles and rigorous buffer management, into a standard operating procedure forms a robust foundation for any SPR-based research or screening campaign, ensuring that the data generated is reliable and reproducible.

Surface Plasmon Resonance (SPR) is a powerful, label-free technique for studying biomolecular interactions in real time, providing critical insights into kinetics, affinity, and specificity. However, the reliability of the data it produces is highly dependent on the stability of the baseline signal. Baseline drift, a gradual shift in the response signal when no active binding is occurring, is a prevalent challenge that can compromise data quality. Within the context of a broader thesis on using start-up cycles to minimize SPR drift, this application note details how drift directly corrupts kinetic and affinity measurements. We outline specific, actionable protocols to identify, mitigate, and correct for drift, thereby safeguarding the integrity of your binding data.

The following diagram illustrates the primary causes of baseline drift and their direct consequences on data analysis.

The Critical Impact of Drift on Data Analysis

Baseline drift is not merely a visual nuisance; it introduces systematic errors that distort the fundamental parameters derived from SPR sensorgrams. Understanding these impacts is crucial for accurate data interpretation.

Kinetic Errors

Kinetic analysis relies on precisely modeling the rates of association (k_a) and dissociation (k_d). Drift directly corrupts this process:

- Distorted Dissociation Phases: During the dissociation phase, a downward drift artificially accelerates the apparent decay of the signal, leading to an overestimation of the dissociation rate constant (

k_d) [11]. Conversely, an upward drift makes the complex appear more stable, leading to an underestimation ofk_d. - Corrupted Association Phases: Drift during the association phase alters the shape of the binding curve, preventing an accurate fit to the Langmuir binding model and resulting in an erroneous association rate constant (

k_a).

Since the equilibrium constant K_D is calculated as k_d / k_a, errors in either rate constant propagate, producing an inaccurate measure of binding affinity [11].

Affinity Misinterpretation

For interactions that reach steady state, the response at equilibrium (R_eq) is used to directly calculate K_D. Baseline drift prevents a stable R_eq measurement. A drifting baseline makes it impossible to determine the true plateau response, leading to incorrect R_eq values at each analyte concentration and a flawed binding isotherm [11]. This can make a weak interaction appear strong, or vice versa.

Quantifying the Impact of Drift

The table below summarizes how different types of drift affect key SPR-derived parameters.

Table 1: Impact of Baseline Drift on SPR Data Quality

| Type of Drift | Impact on Dissociation Rate (k_d) | Impact on Association Rate (k_a) | Impact on Affinity (K_D) | Effect on Steady-State Analysis |

|---|---|---|---|---|

| Upward Drift | Underestimated | Overestimated | Overestimated (False weakening) | Overestimation of R_eq |

| Downward Drift | Overestimated | Underestimated | Underestimated (False strengthening) | Underestimation of R_eq |

| Variable Drift | Unreliable, poor model fit | Unreliable, poor model fit | Highly unreliable | Inaccurate binding isotherm |

Experimental Protocol: A Systematic Approach to Minimize Drift

This protocol provides a step-by-step methodology to proactively minimize baseline drift through meticulous system preparation and the strategic use of start-up cycles.

Pre-Experimental Setup and Buffer Preparation

Proper preparation is the first line of defense against drift.

- Step 1: Buffer Preparation. Prepare a 2-liter batch of running buffer to be used for the entire experiment to ensure consistency [1]. Filter the buffer through a 0.22 µm filter and degas thoroughly to prevent the formation of air spikes or bubbles, which are a common cause of drift and instability [1] [8]. Add detergents (e.g., Tween-20) after the degassing step to prevent foam formation [1].

- Step 2: System Priming and Equilibration. After any buffer change or system start-up, prime the instrument with the new running buffer. Flow the running buffer at the experimental flow rate until a stable baseline is achieved. This can take 5–30 minutes, but after docking a new sensor chip or an immobilization procedure, extended equilibration—even overnight—may be necessary for optimal stability [1] [8].

- Step 3: Sensor Chip Selection and Immobilization. Choose a sensor chip chemistry that minimizes non-specific binding for your specific ligands [10] [5]. During immobilization, aim for an appropriate ligand density. Excessively high density can lead to steric hindrance and worsen post-immobilization wash-out drift.

Implementing Start-Up Cycles

Start-up cycles, also known as conditioning or dummy cycles, are the cornerstone of stabilizing the SPR system before critical data collection.

- Step 4: Design of Start-Up Cycles. In the experimental method, program a minimum of three start-up cycles [1]. These cycles should be identical to the analytical cycles, including any regeneration steps, but should inject running buffer instead of analyte.

- Step 5: Execution. Run the start-up cycles to "prime" the sensor surface and the fluidics. These cycles serve to condition the surface, wash out residual chemicals from immobilization, and stabilize the system following the docking of the chip [1].

- Step 6: Exclusion from Analysis. The data from these start-up cycles are used for system stabilization only and must not be included in the final data analysis or used as blank injections [1].

Incorporating Blank Injections and Double Referencing

Even with a stabilized system, incorporating blanks and a robust referencing strategy is essential to correct for any residual drift.

- Step 7: Blank Injections. Throughout the experimental run, intersperse blank injections (running buffer only) among the analyte injections. It is recommended to include one blank cycle for every five to six analyte cycles [1].

- Step 8: Double Referencing. During data processing, apply double referencing. First, subtract the signal from a reference flow cell (without ligand) from the active flow cell signal. Second, subtract the averaged response from the blank injections. This two-step process effectively compensates for bulk refractive index effects, systemic drift, and differences between channels [1].

The following workflow integrates these protocols into a coherent experimental sequence.

Data Analysis and Drift Correction Protocols

When drift is present in a dataset, specific analysis strategies can be employed to correct for its effects.

Advanced Referencing Techniques

- Protocol for Double Referencing.

- Reference Surface Subtraction: Subtract the sensorgram from a reference flow cell (coated with an inert protein or bare surface) from the active ligand surface sensorgram. This removes system-wide drift and bulk refractive index shifts.

- Blank Injection Subtraction: Average the responses from all blank injections and subtract this average from all analyte sensorgrams. This step corrects for any residual, surface-specific drift and channel differences [1].

Utilizing Drift-Corrected Binding Models

For systems with persistent, linear drift, some analysis software offers built-in correction models.

- Langmuir with Drift Model: In instruments like the ProteOn XPR36, the "Langmuir with drift" model can be applied. This model fits a linear drift term simultaneously with the kinetic constants (

k_aandk_d), effectively isolating the binding signal from the background drift [11]. This is particularly useful for capture surfaces where the ligand may slowly dissociate from the capture reagent.

Table 2: Research Reagent Solutions for Drift Mitigation

| Reagent / Material | Function in Drift Control | Key Considerations |

|---|---|---|

| High-Purity Buffers | Consistent solvent environment; reduces chemical and thermal instability. | Prepare fresh daily, 0.22 µm filtered and degassed [1]. |

| Non-ionic Surfactant (e.g., Tween-20) | Reduces non-specific binding (NSB) to the sensor chip, a source of drift. | Add after degassing to prevent foam; typical concentration 0.01-0.05% [12] [5]. |

| Protein Blocking Additives (e.g., BSA) | Shields unused charged groups on the sensor surface to minimize NSB. | Use at 1% concentration in running buffer during analyte runs only [10]. |

| Streptavidin Sensor Chips (e.g., HC200M) | Provides a stable, oriented surface for biotinylated ligands, promoting uniform behavior. | Hydrogel surface minimizes non-specific binding of cells and proteins [12]. |

| Regeneration Solutions | Fully removes bound analyte without damaging the ligand, preventing carryover. | Scout mildest effective solution (e.g., low pH, high salt) to maintain ligand activity [10]. |

Baseline drift in SPR is a significant source of error that can lead to the miscalculation of kinetic parameters and a fundamental misunderstanding of binding affinity. By understanding its sources and impacts, researchers can implement robust experimental designs. The strategic use of start-up cycles, combined with meticulous buffer preparation, proper surface selection, and the application of double referencing in data analysis, forms a comprehensive defense against drift. Adopting these protocols ensures the generation of high-quality, reliable SPR data, which is crucial for informed decision-making in basic research and drug discovery.

In Surface Plasmon Resonance (SPR) research, baseline drift is a frequent challenge that compromises data quality, leading to inaccurate kinetic and affinity measurements. Drift is typically characterized by a gradual, undesired shift in the baseline response signal, often caused by inadequate buffer equilibration, sensor surface instability, or changes in experimental conditions [1]. In the context of a drug development workflow, such inconsistencies can obscure true binding events, reduce assay sensitivity, and ultimately hinder the reliable characterization of biomolecular interactions.

The concept of Start-Up Cycles is a systematic procedural intervention designed to proactively minimize this drift. This method involves running a series of initial, non-data-collection cycles that mimic the actual experiment but use a blank solution (running buffer) instead of analyte [1]. The primary objective is to condition the sensor chip surface and the fluidic system, allowing them to reach a state of equilibrium before critical data collection begins. This guide details the foundational principles and provides actionable protocols for integrating start-up cycles into SPR experiments, thereby enhancing data reliability for researchers and scientists in pharmaceutical development.

Conceptual Foundation of Start-Up Cycles

The Problem of Baseline Drift in SPR

Baseline drift is more than a mere nuisance; it is a significant source of experimental noise that can invalidate sophisticated assay setups. It is often a sign of a non-optimally equilibrated sensor surface [1]. Common root causes include:

- Systemic Equilibration Issues: Drift is frequently observed after docking a new sensor chip or following an immobilization procedure. This can be due to the rehydration of the surface or the wash-out of chemicals used during immobilization [1].

- Buffer-Related Inconsistencies: Failing to prime the system adequately after a buffer change can result in a "waviness pump stroke" as the previous buffer mixes with the new one in the pump, causing signal instability [1].

- Start-Up Instability: Some sensor surfaces are inherently sensitive to the initiation of flow after a period of standstill, leading to a transient drift that can take 5–30 minutes to level out [1].

Without addressing these issues, the subsequent analytical data, which is crucial for calculating kinetic parameters like association ((k{on})) and dissociation ((k{off})) rates, will be fundamentally flawed.

The Principle of System Conditioning

The core idea behind start-up cycles is system conditioning. The instrument's fluidics, tubing, and most importantly, the sensor surface itself, require a stabilization period to perform predictably. By executing several dummy injections, the system is "primed," which helps to stabilize the baseline by completing initial rehydration, removing loosely bound contaminants, and allowing the immobilized ligand to adjust to the flow buffer [1]. This process establishes consistent drift rates between different flow channels, which is a critical prerequisite for reliable double referencing during data analysis [1].

Core Principles and Implementation Protocol

The Five Core Principles of Start-Up Cycles

Implementing start-up cycles effectively is guided by several key principles:

- Preemptive Stabilization: The primary purpose is to identify and correct for initial instability before valuable samples and data are collected.

- Process Consistency: Start-up cycles should be an immutable part of every SPR method, ensuring reproducibility across experiments and different operators.

- Surface Priming: These cycles are specifically designed to condition the active sensor surface and the reference surface to a similar state.

- Wasteful by Design: The cycles are intended to be excluded from the final analysis; they are an investment in data quality, not a source of data itself.

- Integration with Referencing: Start-up cycles work synergistically with double referencing by establishing a stable starting point from which both bulk and reference channel subtraction can be effectively applied [1].

Detailed Experimental Protocol

The following protocol provides a step-by-step guide for integrating start-up cycles into a standard SPR kinetics experiment.

Pre-Experiment Preparation

- Buffer Preparation: Prepare a fresh running buffer daily. Filter (0.22 µm) and degas the buffer to prevent air spikes. It is considered bad practice to add fresh buffer to old stock [1].

- System Priming: Prime the entire fluidic system with the running buffer. If the system has been idle or if the buffer has been changed, prime several times or flow buffer for an extended period (e.g., 30-60 minutes) to ensure complete equilibration [1].

- Sensor Chip Docking: Dock a new sensor chip and initiate a continuous flow of running buffer. Allow the baseline to stabilize. For new or newly immobilized chips, this may require flowing buffer for an extended period, potentially even overnight, to achieve full equilibration [1].

Designing and Executing the Start-Up Cycles

- Cycle Definition: In your SPR instrument software method, define a standard sample cycle that includes:

- A brief stabilization period (e.g., 60-180 seconds).

- An injection of the analyte (to be replaced with buffer for start-up cycles).

- A dissociation period.

- A regeneration step (if applicable for your assay).

- Incorporate Start-Up Cycles: Duplicate this cycle at least three times at the very beginning of the method sequence [1].

- Modify Start-Up Injections: In these initial cycles, substitute the analyte injection with an injection of running buffer. All other parameters (flow rate, contact time, dissociation, and regeneration) should remain identical to the experimental cycles.

- Execution: Run the method. The instrument will execute the start-up cycles first. Visually inspect the sensorgrams in real-time to confirm that the baseline is stabilizing and that the drift is minimal and consistent across channels before the first analyte injection begins.

- Exclusion from Analysis: During data processing, explicitly exclude the start-up cycles from analysis. Do not use them as blank injections for referencing [1].

Workflow Visualization

The logical flow from system preparation to stable operation is depicted below.

Associated Reagents and Materials

The successful implementation of start-up cycles relies on the use of high-quality reagents and materials. The following table details key research reagent solutions essential for this protocol.

Table 1: Essential Research Reagent Solutions for Start-Up Cycle Implementation

| Item | Function/Description | Application Notes |

|---|---|---|

| Running Buffer (e.g., HBS-EP+) | Maintains a stable ionic strength and pH; surfactants (e.g., P20) reduce non-specific binding. | Must be prepared fresh daily, 0.22 µm filtered and degassed to prevent baseline spikes and drift [1] [5]. |

| Sensor Chip (e.g., CM5, NTA, SA) | The platform for ligand immobilization. Choice depends on ligand properties and coupling chemistry. | Requires proper pre-conditioning; surface chemistry must be chosen to minimize non-specific binding [5]. |

| Regeneration Solution (e.g., Glycine pH 1.5-2.5) | Removes bound analyte from the ligand surface without damaging it, resetting the surface for the next cycle. | Concentration and pH must be optimized for each specific ligand-analyte pair to ensure complete regeneration and surface stability [1] [5]. |

| Blocking Agent (e.g., Ethanolamine, BSA) | Deactivates any remaining active groups on the sensor surface after immobilization. | Critical for minimizing non-specific binding, which can contribute to baseline drift and false positives [5]. |

Validation and Data Analysis

Quantitative Assessment of Protocol Efficacy

To objectively validate the effect of start-up cycles, researchers can compare key baseline metrics from experiments with and without the protocol. The following table summarizes expected outcomes.

Table 2: Quantitative Impact of Start-Up Cycles on SPR Baseline Stability

| Performance Metric | Without Start-Up Cycles | With Start-Up Cycles (≥3) | Measurement Method |

|---|---|---|---|

| Time to Stable Baseline | 5 - 30+ minutes [1] | < 5 minutes | Time from flow start until baseline drift is < 0.5 RU/min. |

| Average Baseline Drift Rate | Can be significant and variable | < 1 RU/minute [1] | Slope of the baseline response unit (RU) over time. |

| Noise Level | Often elevated (> 1 RU) | Typically < 1 RU [1] | Standard deviation of the baseline signal during a buffer injection. |

| Inter-Channel Drift Consistency | Often inconsistent | Establishes equal drift rates [1] | Comparison of drift rates between active and reference flow channels. |

Integrating Start-Up Cycles with Double Referencing

Start-up cycles are a foundational step that enhances the effectiveness of double referencing. The following diagram illustrates this integrated data refinement pathway.

The process begins with the raw data. The stabilization achieved by start-up cycles ensures that the subsequent referencing steps are applied to a consistent baseline. The first subtraction step accounts for bulk refractive index shifts and instrument noise, while the second subtraction, using blank injections spaced throughout the experiment, corrects for any residual differences between the reference and active channels [1]. This multi-layered approach is critical for producing high-fidelity binding data.

How Start-Up Cycles Prime the System and Stabilize the Sensor Surface

Surface Plasmon Resonance (SPR) is a powerful, label-free technique for analyzing biomolecular interactions in real time. A common challenge in obtaining high-quality, reproducible SPR data is baseline drift, often caused by improperly equilibrated sensor surfaces and fluidic systems. This application note details the critical practice of using start-up cycles—initial injections of running buffer that mimic experimental conditions—to prime the system and stabilize the sensor surface. We provide a definitive protocol for integrating start-up cycles into SPR methods, effectively minimizing baseline drift and its detrimental effects on data quality. When implemented as part of a rigorous experimental setup, this procedure enhances the reliability of kinetic and affinity measurements, which is paramount for critical applications in drug discovery and development.

In Surface Plasmon Resonance (SPR) experiments, the baseline signal is the foundation upon which all binding data is interpreted. Baseline drift, a gradual shift in this signal over time, is a frequent indicator of a non-optimally equilibrated system [1]. This drift can stem from multiple sources, including the rehydration of a new sensor chip, wash-out of chemicals from the immobilization procedure, or a simple lack of thermal and hydrodynamic stability in the fluidic system [1]. A drifting baseline complicates data analysis, leading to inaccurate determination of binding responses and, consequently, erroneous kinetic and affinity constants.

The process of system equilibration involves flowing running buffer over the sensor surfaces until a stable baseline is achieved. However, even after the bulk signal appears stable, the first few experimental cycles can induce minor shifts as the surface and instrument adjust to the repeated injections and regeneration steps. Start-up cycles are specifically designed to address this period of initial instability. These cycles, which are buffer-only injections that mirror the full experimental method, serve to "prime" or "condition" both the sensor chip and the fluidic instrumentation, leading to a truly stable platform for data collection [1].

The Role and Design of Start-Up Cycles

Start-up cycles are dummy runs executed at the beginning of an SPR experiment before any analyte samples are injected. Their primary function is to absorb the initial system instability, ensuring that all subsequent sample injections occur under consistent and reproducible conditions.

A well-designed start-up cycle incorporates all the phases of a standard experimental cycle:

- Baseline Monitoring: Establishes a pre-injection baseline.

- Buffer Injection: Mimics the sample injection phase but uses only running buffer.

- Dissociation Phase: Allows the system to stabilize after injection.

- Regeneration (if used): Applies the regeneration solution to the surface, conditioning it for the next cycle [1].

By executing this sequence several times, the sensor surface becomes fully acclimated to the buffer, flow conditions, and regeneration chemicals. Furthermore, this process helps identify any unforeseen issues with the method or surface stability before valuable samples are consumed. It is critical to note that these start-up cycles are not used as blanks in the final data analysis; their sole purpose is system stabilization [1].

Experimental Protocol: Implementing Start-Up Cycles

The following section provides a detailed, step-by-step protocol for integrating start-up cycles into a standard SPR experiment to minimize baseline drift.

Pre-Experimental Preparation

- Buffer Preparation: Prepare a sufficient volume of running buffer fresh each day. Filter the buffer through a 0.22 µm filter and degas it thoroughly to prevent air spikes in the sensorgram. Store filtered buffer in a clean, sterile bottle at room temperature [1].

- System Priming: Prime the SPR instrument with the freshly prepared running buffer multiple times to ensure the entire fluidic path is equilibrated. Always prime the system after any buffer change [1].

- Sensor Chip Docking: Dock a new or freshly cleaned sensor chip. If the chip has been stored dry, allow the system to flow running buffer over it to rehydrate the surface fully. This initial rehydration can cause significant drift and may require an extended period of buffer flow, potentially even overnight, to stabilize [1].

- Ligand Immobilization: Immobilize the ligand onto the sensor surface using standard covalent (e.g., EDC/NHS) or capture methods. Following immobilization, flow running buffer to wash out any residual chemicals and allow the baseline to stabilize.

Method Design and Execution

- Incorporate Start-Up Cycles: In the experimental method software, program at least three start-up cycles at the very beginning of the run sequence [1].

- Configure Cycle Parameters: Design these cycles to be identical to the sample cycles, including:

- The same flow rate.

- The same injection time.

- The same dissociation time.

- The same regeneration solution and contact time (if applicable).

- The key difference is that the "analyte" injected is running buffer alone.

- Execute and Monitor: Run the method. Observe the sensorgrams from the start-up cycles. The baseline should show progressively less drift from the first to the third cycle, culminating in a stable, flat baseline at the start of the first sample cycle.

- Proceed with Experiment: Once the start-up cycles are complete, proceed with the injection of analyte samples. The system is now considered primed and stabilized for data collection.

Complementary Best Practices

- Blank Injections: In addition to start-up cycles, intersperse blank (buffer) injections evenly throughout the experiment, approximately every five to six analyte cycles. These blanks are used for double referencing during data analysis, which compensates for residual bulk effects and drift [1].

- Buffer Hygiene: Never add fresh buffer to old buffer remaining in the system. Always use a fresh, clean bottle for the aliquot to be degassed and used in the experiment to prevent microbial growth or contamination [1].

- Environmental Control: Perform experiments in a controlled environment, as temperature fluctuations can directly impact baseline stability [5].

The following workflow summarizes the complete experimental process incorporating start-up cycles:

Data Presentation: Quantitative Impact of Start-Up Cycles

The following table summarizes the key parameters and expected outcomes from implementing a start-up cycle protocol.

Table 1: Protocol Summary and Expected Outcomes for Start-Up Cycles

| Parameter | Specification | Purpose & Rationale |

|---|---|---|

| Number of Cycles | Minimum of 3 [1] | Conditions the surface to the experimental rhythm and absorbs initial instability caused by regeneration solutions and flow start-up. |

| Injection Solution | Running Buffer Only | Mimics the injection process without consuming analyte, allowing the system to stabilize hydraulically and thermally. |

| Data Usage | Excluded from analysis [1] | These are stabilization steps, not experimental controls, and should not be used for referencing. |

| Expected Outcome | Flat, stable baseline at the start of the first sample cycle. Reduced noise (< 1 RU) during buffer injections [1]. | Ensures that subsequent analyte binding responses are measured from a consistent baseline, improving kinetic parameter accuracy. |

| Complementary Practice | Include blank injections every 5-6 sample cycles [1]. | Provides data for double referencing, which subtracts systemic noise and drift from sample sensorgrams. |

The Scientist's Toolkit: Essential Reagents and Materials

A successful SPR experiment relies on more than just a well-tuned protocol. The following table lists key reagents and materials crucial for maintaining system stability and minimizing drift.

Table 2: Essential Research Reagent Solutions for Stable SPR Experiments

| Item | Function in Experiment | Key Consideration |

|---|---|---|

| Running Buffer | Maintains pH and ionic strength; the liquid environment for interactions. | Prepare fresh daily, 0.22 µm filter and degas to prevent air spikes [1]. |

| Regeneration Solution | Removes bound analyte from the ligand to regenerate the surface. | Must be strong enough to remove analyte but not damage the immobilized ligand [5]. |

| Sensor Chip | Platform with a gold film and modified surface for ligand immobilization. | Select based on ligand properties (e.g., CM5 for proteins, C1 for large nanoparticles) [13] [5]. |

| Blocking Agents | Reduce non-specific binding by occupying unused active sites on the chip surface. | Common agents include ethanolamine, casein, or BSA [5]. |

| Detergents | Further reduce non-specific binding in the running buffer. | Additives like Tween-20 (e.g., 0.05%) are added after degassing to prevent foam [1] [5]. |

Integrating start-up cycles is a simple yet profoundly effective strategy for enhancing the quality of SPR data. By proactively conditioning the sensor surface and fluidic system, researchers can effectively minimize baseline drift, a common source of error in quantitative binding analyses. This protocol, when combined with rigorous buffer management and proper referencing techniques, establishes a robust foundation for obtaining reliable kinetic and affinity constants. The consistent application of these practices is essential for accelerating drug discovery pipelines, where the accuracy of biomolecular interaction data directly impacts critical development decisions.

Implementing Start-Up Cycles: A Step-by-Step Protocol for SPR Practitioners

Surface Plasmon Resonance (SPR) is a powerful label-free technique for studying biomolecular interactions in real-time, providing critical data on kinetics, affinity, and specificity [5]. However, a significant challenge in obtaining reliable, high-quality data is SPR drift, a phenomenon where the baseline signal gradually shifts over time, potentially leading to inaccurate measurements and compromised results [5]. This drift can stem from various sources, including temperature fluctuations, uneven buffer mixing, or instability of the sensor chip surface itself.

This document frames the use of start-up cycles within a broader thesis on minimizing SPR drift. Start-up cycles consist of a series of initial, conditioning runs performed before formal data collection begins. Their purpose is to stabilize the sensor surface and the fluidics system, thereby reducing baseline drift and improving the reproducibility of subsequent experimental cycles. Here, we provide detailed application notes and protocols for researchers to determine the optimal number and strategic placement of these critical start-up cycles within their SPR methods.

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key reagents and materials essential for performing SPR experiments with integrated start-up cycles.

Table 1: Key Research Reagent Solutions for SPR Experiments

| Item | Function/Explanation |

|---|---|

| Sensor Chips | The foundation for immobilizing ligands. Choice (e.g., CM5 for covalent coupling, NTA for His-tagged proteins, SA for biotinylated ligands) must align with immobilization strategy and analyte properties [5]. |

| Running Buffer | Maintains a stable environment for interactions. Its composition (salts, pH stabilizers, potential additives like surfactants) is critical for minimizing non-specific binding and baseline drift [5]. |

| Regeneration Buffer | Removes bound analyte from the ligand surface without damaging it. Essential for reusing the sensor chip and is a key component of start-up cycles [5]. |

| Ligand & Analyte | The molecules under study. Their purity, concentration, and activity are paramount; impurities are a major source of noise and drift [5]. |

| Immobilization Reagents | Chemicals like EDC/NHS for covalent coupling. Efficient immobilization ensures stable ligand density, which contributes to a stable baseline [5]. |

| Blocking Agents | Solutions (e.g., ethanolamine, BSA) used to cap remaining active sites on the sensor surface, thereby minimizing non-specific binding [5]. |

Core Protocol: Implementing Start-Up Cycles

This section provides a detailed, step-by-step methodology for integrating start-up cycles into an SPR method.

The following diagram illustrates the logical workflow and decision points for incorporating start-up cycles into your SPR experiment.

Detailed Step-by-Step Methodology

Step 1: System and Sensor Chip Preparation

- Prime the Fluidic System: Flush the entire SPR instrument fluidics system with filtered and degassed running buffer for at least 30 minutes to remove air bubbles and equilibrate the temperature. Consistent buffer composition is critical [5].

- Sensor Chip Mounting and Initial Conditioning: Mount the sensor chip according to the manufacturer's instructions. For a new or stored chip, perform a preconditioning cycle as recommended, which may involve a brief injection of a mild regeneration solution (e.g., 10 mM Glycine pH 2.0-3.0) to clean and stabilize the gold surface [5].

Step 2: Execution of Start-Up Cycles

- Cycle Composition: Program the instrument to run 3 to 5 initial start-up cycles. Each cycle should mimic a full experimental cycle but without a ligand or with a reference surface. A standard start-up cycle consists of:

- Baseline stabilization with running buffer for 300-600 seconds.

- Injection of running buffer (as a mock analyte) for 60-120 seconds.

- Dissociation phase with running buffer for 120-180 seconds.

- Injection of a regeneration buffer for 30-60 seconds.

- Placement: These cycles must be performed after system priming but immediately before the ligand immobilization step. This ensures the surface and fluidics are in the most stable state possible before committing your precious sample.

Step 3: Stability Assessment and Optimization

- Quantitative Monitoring: During the start-up cycles, closely monitor the baseline signal. Calculate the drift rate (in Resonance Units per second, RU/sec) over the final 60 seconds of the baseline stabilization period in each cycle.

- Decision Point: The optimal number of start-up cycles is determined by the stabilization of the baseline drift rate. The process should continue until the drift rate falls below a pre-defined threshold (e.g., < 0.5 RU/sec) and shows minimal change between consecutive cycles. If the baseline remains unstable after 5 cycles, investigate other potential issues like buffer mismatch, temperature fluctuations, or a contaminated sensor chip [5].

Data Presentation and Analysis

Impact of Start-Up Cycles on Data Quality

The following table summarizes quantitative data from a simulated experiment, demonstrating the effect of start-up cycles on key experimental parameters.

Table 2: Quantitative Impact of Start-Up Cycles on SPR Assay Performance

| Number of Start-Up Cycles | Average Baseline Drift Rate (RU/sec) | Noise Level (RU, RMS) | Reproducibility (Chi² Value for Kinetic Fit) | Recommended Use Case |

|---|---|---|---|---|

| 0 Cycles | 2.5 - 5.0 | 1.5 - 3.0 | > 20 | Not recommended. |

| 1 Cycle | 1.0 - 1.8 | 0.8 - 1.5 | 10 - 15 | Preliminary scouting runs. |

| 3 Cycles | 0.3 - 0.7 | 0.3 - 0.6 | 5 - 10 | Standard high-quality kinetics. |

| 5 Cycles | 0.1 - 0.3 | 0.2 - 0.4 | < 5 | High-precision applications and low-affinity measurements. |

Advanced Optimization: A Machine Learning-Driven Approach

Emerging research suggests that sensor optimization, including stabilization protocols, can be significantly accelerated using Machine Learning (ML) and Explainable AI (XAI) [14]. While traditionally applied to design parameters like gold thickness and pitch, this data-driven philosophy can be extended to experimental conditions.

- Methodology: A large dataset can be generated by varying start-up cycle parameters (number, buffer composition, flow rate) and measuring outcomes (drift rate, noise, final data quality). ML regression models (e.g., Random Forest, Gradient Boosting) can then predict the optimal protocol for a given experimental setup [14].

- Interpretation with XAI: Techniques like SHAP (Shapley Additive exPlanations) can identify which start-up parameters most significantly influence baseline stability. For instance, it might reveal that for a specific sensor chip type, the number of cycles is the most critical factor, while for another, buffer ionic strength is paramount [14]. This logical relationship is shown below.

Troubleshooting and Validation

Even with start-up cycles, issues can arise. The table below outlines common problems and their solutions.

Table 3: Troubleshooting Guide for Start-Up Cycle Implementation

| Problem | Potential Cause | Solution |

|---|---|---|

| Persistent High Drift | Buffer mismatch/contamination, temperature instability, faulty sensor chip. | Re-prepare buffers, ensure instrument calibration and temperature control, try a new sensor chip [5]. |

| Poor Reproducibility | Inconsistent regeneration during start-up cycles, variation in ligand immobilization. | Standardize regeneration protocol between cycles; optimize and quantify ligand immobilization density [5]. |

| Low Signal Post-Stabilization | Overly aggressive regeneration during start-up, ligand denaturation. | Use a milder regeneration buffer for start-up cycles; verify ligand activity after immobilization [5]. |

Validation of the Method: A successful start-up cycling protocol is validated by a low and stable baseline drift rate, high signal-to-noise ratio in subsequent analyte binding steps, and excellent reproducibility between replicate measurements and across different sensor chips. The kinetic parameters (ka, kd, KD) derived from the experiment should have low confidence interval errors and align with values obtained from other established techniques, confirming the reliability of the data generated.

Surface Plasmon Resonance (SPR) is a powerful technique for studying biomolecular interactions in real time. A common challenge in SPR experiments is baseline drift, which can compromise data quality and lead to erroneous kinetic analysis [1]. Baseline drift is frequently observed after docking a new sensor chip or following ligand immobilization, often due to rehydration of the surface or wash-out of chemicals from the immobilization procedure [1].

Implementing a robust start-up cycle protocol featuring buffer injections and regeneration steps is critical for system equilibration, significantly minimizing baseline drift and ensuring high-quality, reproducible data [1] [8]. This application note provides detailed methodologies for employing start-up cycles to stabilize SPR systems before formal data collection begins.

Key Principles of Start-Up Cycles

Start-up cycles, sometimes called "dummy injections," are preliminary runs performed before analyte samples are injected. These cycles use running buffer instead of analyte and include all other method steps, such as regeneration [1]. Their primary functions are:

- System Equilibration: Allowing the sensor surface and fluidics to stabilize after docking or immobilization [1].

- Surface "Priming": Conditioning the surface by exposing it to initial regeneration cycles, which can help stabilize immobilised ligands and reduce drift during actual experimental cycles [1].

- Stabilization of Drift Rates: Establishing equal drift rates between reference and active surfaces, which is crucial for accurate double referencing in experiments with long dissociation times [1].

Materials and Reagents

Research Reagent Solutions

Table 1: Essential reagents and materials for SPR start-up cycles

| Reagent/Material | Function | Key Considerations |

|---|---|---|

| Running Buffer | Continuous flow medium; defines chemical environment for interactions [1]. | Prepare fresh daily, 0.22 µm filtered and degassed. Use one consistent batch per experiment [1] [8]. |

| Regeneration Solution | Removes bound analyte from immobilised ligand, resetting the surface [1]. | Type and concentration depend on ligand-analyte pair. Must effectively regenerate without damaging ligand activity. |

| Sensor Chip | Platform with functionalized surface for ligand immobilization [5]. | Choice (e.g., CM5, NTA, SA) depends on immobilization chemistry and ligand properties [5]. |

| Filtered, Degassed Water | For system cleaning and preparation [1]. | Used in preparation of all buffers to prevent air bubble formation and particle introduction. |

| Desorb/Sanitize Solution | For thorough system cleaning when "wave" curves or persistent drift indicate contamination [8]. | Used if basic priming and start-up cycles fail to stabilize baseline. |

Experimental Protocol

Pre-Experiment System Preparation

- Buffer Preparation: Prepare at least 2 liters of running buffer. Filter through a 0.22 µm filter and degas thoroughly. Store in a clean, sterile bottle at room temperature. Avoid storing buffers at 4°C before degassing, as this increases dissolved air content [1].

- System Priming: After any buffer change or at the start of a method, prime the system thoroughly. This replaces the liquid in the pumps and tubing, preventing mixing of different buffers that causes waviness in the baseline [1] [8].

- Baseline Monitoring: Flow running buffer at the experimental flow rate and monitor the baseline signal. Wait until a stable baseline is achieved before proceeding. This may take 5-30 minutes or, in some cases (e.g., after immobilization), overnight equilibration is recommended [1].

Designing the Start-Up Cycle Method

A minimum of three start-up cycles is recommended [1]. These cycles should be identical to the experimental cycles but inject running buffer instead of analyte sample.

Table 2: Quantitative profile of a typical start-up injection cycle

| Step | Duration (Minutes) | Flow Rate (µL/min) | Solution | Purpose |

|---|---|---|---|---|

| Baseline Stabilization | 5 - 15 | 10 - 30 | Running Buffer | Allows signal to stabilize after any flow change [1] [8]. |

| Buffer Injection | 1 - 5 | 10 - 30 | Running Buffer | Mimics analyte injection without binding, conditioning the flow path. |

| Dissociation | 1 - 5 | 10 - 30 | Running Buffer | Mimics the dissociation phase of a real sample. |

| Regeneration | 0.5 - 2 | 10 - 30 | Regeneration Solution | Resets the surface, "priming" it for subsequent cycles [1]. |

| Re-equilibration | 2 - 5 | 10 - 30 | Running Buffer | Re-stabilizes the surface in running buffer after regeneration. |

Workflow Visualization

The following diagram illustrates the logical sequence and decision-making process for implementing start-up cycles in an SPR experiment.

Diagram 1: Workflow for SPR start-up cycle implementation

Data Interpretation and Analysis

Evaluating Start-Up Cycle Sensorgrams

- Successful Stabilization: Sensorgrams from successive start-up cycles should show minimal baseline drift and no "waviness," indicating a well-equilibrated system [1] [8].

- Presence of "Wave" Curves: If buffer injections produce a wavy sensorgram, this often indicates a need for system cleaning. Execute a desorb and sanitize procedure, then re-equilibrate [8].

- Drift and Shift: Persistent drift can be caused by insufficient buffer degassing (leading to micro-bubbles), differences between buffer batches, or inadequate equilibration after immobilization. Ensure buffers are thoroughly degassed and use a single batch per experiment [8].

Incorporating Blanks and Double Referencing

- Blank Injections: Integrate blank cycles (buffer injections spaced evenly throughout the experiment, approximately one every five to six analyte cycles) [1].

- Double Referencing: During data analysis, first subtract the reference flow cell signal from the active flow cell signal. Then, subtract the average response from the blank injections. This two-step process compensates for bulk effects, baseline drift, and differences between channels [1].

Table 3: Troubleshooting common issues during start-up cycles

| Observed Issue | Potential Cause | Recommended Solution |

|---|---|---|

| High Noise Level | Air bubbles in buffer or system; particulate contamination. | Ensure thorough buffer degassing and 0.22 µm filtration. Prime system thoroughly [1]. |

| 'Wave' Curve During Injection | System requires cleaning; poor buffer equilibration. | Perform desorb and sanitize procedure. Re-prime system with fresh, degassed buffer [8]. |

| Consistent Drift | Non-degassed buffers; different buffer batches; surface not equilibrated. | Use one batch of freshly prepared, degassed buffer. Extend initial equilibration time [1] [8]. |

| Spikes at Injection Start/End | Slight phase misalignment between reference and active channels after subtraction. | Use the instrument's inline reference subtraction function if available [8]. |

Integrating a structured start-up cycle protocol is a critical step in obtaining high-quality, reliable data from SPR experiments. By systematically conditioning the sensor surface and fluidics through a series of buffer injections and regeneration steps, researchers can effectively minimize baseline drift, reduce noise, and enhance the overall reproducibility of their kinetic and affinity measurements. This protocol, combined with sound buffer management and double referencing, forms a solid foundation for successful biomolecular interaction analysis.

In Surface Plasmon Resonance (SPR) research, the integrity of real-time binding data is paramount. Baseline drift, a gradual shift in the sensor's response when no active binding occurs, is a common technological artifact that can compromise data quality, leading to inaccurate kinetic and affinity calculations [1] [5]. System priming—the comprehensive process of equilibrating the instrument, fluidics, and sensor surface with running buffer—serves as a critical defensive step against such drift. This document, framed within broader thesis research on start-up cycles to minimize SPR drift, details the application notes and protocols for effective system priming. By establishing a stable baseline, researchers ensure that the observed responses accurately reflect biomolecular interactions, thereby enhancing the reliability of data used in drug development [1].

The Critical Role of System Priming

System priming is fundamentally an equilibration process. Its primary purpose is to minimize the signal noise and drift originating from the instrument and sensor chip rather than the biomolecular interaction under investigation.

The principal causes of baseline drift that priming addresses include:

- Sensor Chip Equilibration: Newly docked or immobilized sensor chips require rehydration and the wash-out of chemicals used during immobilization, causing initial drift [1].

- Buffer Incompatibility: A change in running buffer composition, or the presence of dissolved air in cold buffers, can cause significant signal shifts and "waviness" until the system is fully flushed and equilibrated [1] [5].

- Start-Up Instability: After a period of flow standstill, the initiation of flow can cause a transient drift as the system adjusts to the new pressure and the sensor surface adapts to the flow buffer [1].

Failure to adequately prime the system introduces variables that can obscure true binding signals, making data analysis difficult and potentially erroneous. A well-primed system is characterized by a flat, stable baseline with a low noise level (e.g., < 1 Response Unit (RU)), which is the foundation for high-quality SPR data [1].

Quantitative Data on Priming and Drift Reduction

The following table summarizes key parameters and their quantitative impact on system stability, providing a benchmark for effective priming protocols.

Table 1: Quantitative Guide to System Priming Parameters for Drift Reduction

| Parameter | Sub-Optimal Condition | Optimized Condition | Impact on Baseline Stability |

|---|---|---|---|

| Buffer Preparation | Buffer stored at 4°C; old buffer reused; not filtered/degassed | Fresh buffer prepared daily; 0.22 µM filtered and degassed just before use [1] | Prevents air spikes and signal instability caused by dissolved air and microbial growth [1]. |

| System Equilibration Time | Immediate start of experiment after buffer change or docking | Prime system 2-3 times; flow running buffer for 5-30 minutes until baseline stabilizes [1] | Eliminates "waviness" from buffer mixing and allows for surface rehydration [1]. |

| Start-Up Cycle Number | No start-up cycles; analysis begins with analyte injection | Incorporate at least three start-up cycles (buffer injection + regeneration) before analyte cycles [1] | "Primes" the surface, stabilizing it against effects of initial regeneration cycles; drift is significantly reduced [1]. |

| Noise Level Target | Noise level > 1 RU | Noise level < 1 RU after proper equilibration [1] | Indicates a well-equilibrated system with a low signal-to-noise ratio, essential for detecting small binding responses [1]. |

Detailed Experimental Protocols

Comprehensive System Priming and Equilibration Protocol

This protocol ensures the entire fluidic path and sensor surface are stabilized before data collection.

Objective: To achieve a stable baseline with a noise level of < 1 RU by equilibrating the IFC (Integrated Fluidic Cartridge), tubing, and sensor surface with the running buffer.

Materials:

- Running buffer (freshly prepared, filtered, and degassed) [1]

- Priming solution (as specified by the instrument manufacturer, often the running buffer itself)

Procedure:

- Buffer Preparation: Prepare at least 2 liters of running buffer fresh on the day of the experiment. Filter through a 0.22 µM filter and degas the solution. If a detergent is required, add it after degassing to prevent foam formation [1].

- Initial Priming: Load the running buffer and execute the instrument's "prime" function 2-3 times. This replaces the previous buffer in the pumps and tubing, preventing mixing-induced drift [1] [5].

- Baseline Stabilization: Initiate a continuous flow of running buffer at the experimental flow rate. Monitor the baseline signal in real-time.

- Stability Check: Allow the buffer to flow until the baseline drift levels out. This may take 5 to 30 minutes, depending on the sensor chip type and immobilization chemistry. A stable baseline is defined by a drift of less than 5 RU over a 10-minute period [1].

- Noise Level Assessment: Once stable, perform several dummy injections of running buffer. The average deviation during this buffer injection should be less than 1 RU, indicating a low system noise level [1].

Incorporating Start-Up Cycles into an Experimental Method

Start-up cycles are integrated into the automated method to condition the surface and are excluded from final data analysis.

Objective: To stabilize the sensor surface through simulated analytical cycles, minimizing drift induced by the initial contact with sample and regeneration solutions.

Workflow Logic:

Procedure:

- Method Design: In the experimental software method, define a series of cycles that are identical in structure to the analyte cycles, including surface regeneration steps.

- Buffer Injection: In these start-up cycles, use the running buffer instead of the analyte sample for the injection phase [1].

- Execution: Run at least three of these start-up cycles. The system monitors the baseline response throughout these cycles.

- Exclusion from Analysis: Upon completion, these start-up cycles are not used in the final data analysis or as blank subtractions. Their sole purpose is to condition the surface [1].

The Scientist's Toolkit: Essential Research Reagents

The following materials are crucial for executing an effective system priming and start-up cycle protocol.

Table 2: Essential Reagents for SPR System Priming and Drift Control

| Item | Function / Rationale |

|---|---|

| High-Purity Buffers | Provides a consistent ionic strength and pH environment. Prevents non-specific binding and surface destabilization [5]. |

| 0.22 µm Membrane Filter | Removes particulate matter that could clog the microfluidics of the Instrument Fluidic Cartridge (IFC) and cause pressure spikes [1]. |

| Buffer Degassing Unit | Removes dissolved air to prevent the formation of air bubbles ("air spikes") in the SPR flow cell, which create massive signal artifacts [1]. |

| Appropriate Sensor Chip | The gold surface functionalized with chemistry (e.g., CM5 for amine coupling, NTA for His-tag capture) for ligand immobilization. Selection impacts immobilization level and stability [5]. |

| Surface Regeneration Solution | A solution (e.g., low pH glycine, high salt) that removes bound analyte without damaging the immobilized ligand. Essential for re-using the surface across multiple cycles [1] [5]. |

| Blocking Agent (e.g., BSA, Ethanolamine) | Used to cap unused active sites on the sensor surface after ligand immobilization, thereby reducing non-specific binding of the analyte to the chip matrix [5]. |

Data Analysis: Confirming Priming Efficacy

The success of system priming and start-up cycles is quantitatively assessed during and after the experiment.

- Visual Baseline Inspection: The raw sensorgram should show a flat baseline before analyte injection. A slope or significant "waviness" indicates inadequate priming or the need for more start-up cycles [1].

- Noise Level Calculation: The standard deviation of the baseline signal over a 60-second period immediately before an analyte injection should be calculated. A value of < 0.5-1 RU is indicative of a well-equilibrated system [1].

- Double Referencing: This data processing technique is most effective on a stable baseline. It involves subtracting the response from a reference flow cell to account for bulk refractive index shift, followed by subtracting the response from buffer-only (blank) injections to correct for systematic drift and channel-specific differences [1]. A stable baseline post-referencing confirms the priming was successful.

System priming is not a mere preliminary step but a foundational practice for generating publication-quality SPR data. By meticulously preparing buffers, thoroughly equilibrating the instrument, and strategically employing start-up cycles, researchers can effectively suppress baseline drift. This proactive approach to system management, as framed within the context of start-up cycle research, ensures that the resulting kinetic and affinity parameters are accurate, reliable, and reflective of true biomolecular interactions, thereby accelerating the pace of drug discovery and development.

Quantifiable Targets for Baseline Stability

A stable baseline is the foundational prerequisite for generating reliable Surface Plasmon Resonance (SPR) data. The following table outlines the key quantitative and qualitative targets that researchers should achieve before commencing analyte injections.

Table 1: Quantifiable Targets for a Stable Baseline

| Parameter | Target Value/Range | Measurement Protocol | Interpretation & Significance |

|---|---|---|---|

| Noise Level | < 1 Response Unit (RU) [1] | After system equilibration, inject running buffer several times and observe the average baseline response. | A low noise level (<1 RU) indicates a clean, well-equilibrated fluidic system and instrument, which is essential for detecting small binding signals accurately. |

| Drift Rate | < 5 RU over 5-10 minutes [1] | Monitor the baseline signal under a steady flow of running buffer for 5-10 minutes after equilibration. Calculate the change in RU over time. | Minimal drift signifies a fully equilibrated sensor surface and stable temperature, preventing inaccurate determination of binding start and end points. |

| Start-up Stabilization Time | 5 - 30 minutes [1] | After initiating flow or docking a new chip, observe the time required for the baseline signal to level out. | This duration depends on the sensor type and immobilized ligand. Proceeding before stabilization can compromise initial data cycles. |

| Baseline Flatness | Visually flat; no observable upward or downward trend [1] | Visual inspection of the baseline signal prior to injection. | A flat baseline confirms that the system is in equilibrium, a key requirement for the accurate measurement of binding-induced response changes. |

Experimental Protocol: Implementing Start-up Cycles

This protocol provides a detailed methodology for using start-up cycles to minimize baseline drift and stabilize the SPR system before data collection, directly supporting the thesis research on this topic.

Principle