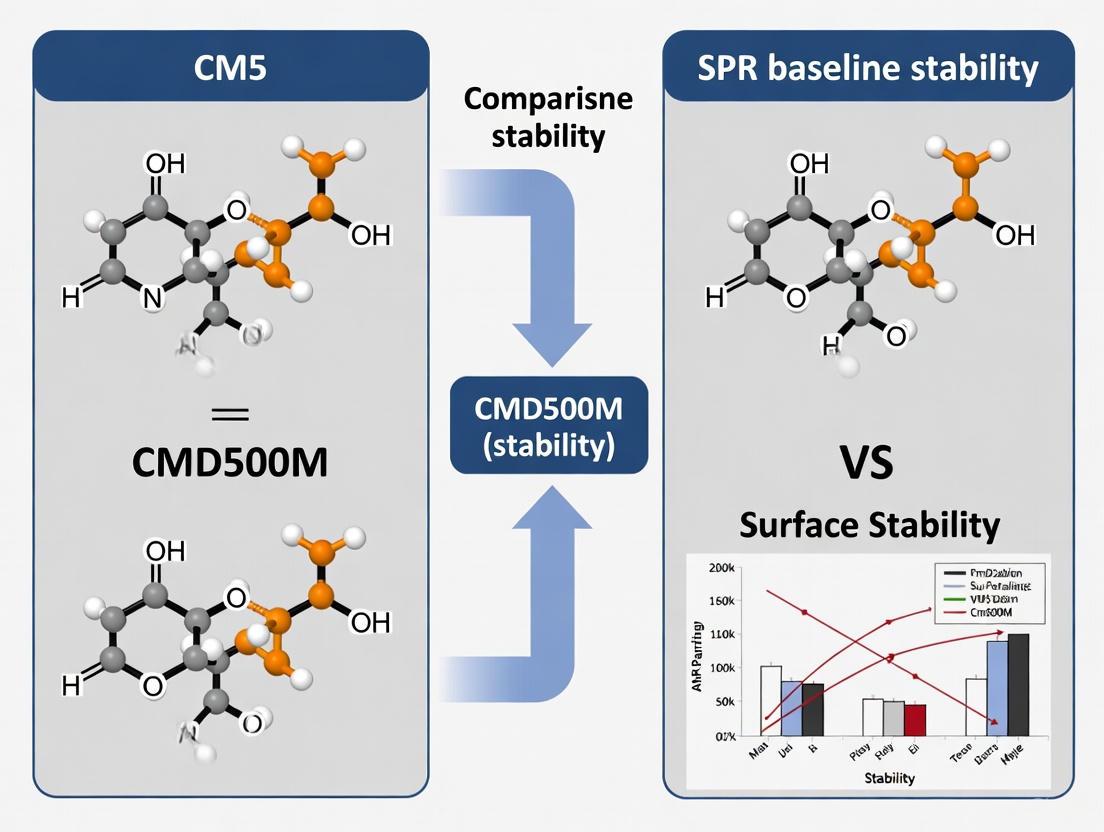

SPR Baseline Stability: A Comparative Analysis of Biacore CM5 and XanTec CMD500M Sensor Chips

This article provides a comprehensive analysis for researchers and drug development professionals on the baseline stability and performance equivalence of the Biacore CM5 optical chip and its sanction-driven analogue, the...

SPR Baseline Stability: A Comparative Analysis of Biacore CM5 and XanTec CMD500M Sensor Chips

Abstract

This article provides a comprehensive analysis for researchers and drug development professionals on the baseline stability and performance equivalence of the Biacore CM5 optical chip and its sanction-driven analogue, the XanTec CMD500M. It covers the foundational principles of SPR and the critical role of baseline stability, outlines methodological approaches for robust experimental design, presents troubleshooting strategies for common stability issues, and delivers a direct comparative validation of kinetic parameters and operational performance based on a recent 2024 study. The findings confirm the practical interchangeability of these chips, a critical consideration for labs facing supply chain constraints.

Understanding SPR Baseline Stability and Its Impact on Data Quality

Core Principles of Surface Plasmon Resonance (SPR) Biosensing

Surface Plasmon Resonance (SPR) is a powerful, label-free optical biosensing technique that enables real-time monitoring of molecular interactions [1]. Since its introduction in the early 1990s, SPR has proven to be one of the most powerful technologies for determining specificity, affinity, and kinetic parameters during macromolecular binding events [1]. This technique measures refractive index changes in the vicinity of thin metal films (typically gold) in response to biomolecular interactions, eliminating the need for specialized tags or dyes that could cause steric hindrance or alter structural configurations [1] [2]. The ability to study interactions without labels allows researchers to observe native molecular behavior with high sensitivity, making SPR invaluable across biomedical research, drug discovery, diagnostics, and bioengineering [1] [3].

The fundamental principle underlying SPR technology involves the generation of surface plasmons—electron charge density waves that propagate parallel to a metal-dielectric interface when excited by polarized light [3]. In commercial SPR biosensors, this is typically achieved using a high-refractive-index glass prism in the Kretschmann configuration of the attenuated total reflection method [1]. When biomolecular binding occurs on the sensor surface, it alters the local refractive index, changing the resonance conditions that can be precisely measured [1]. This change is directly proportional to the mass concentration of molecules bound to the surface, allowing for quantitative assessment of binding interactions [1].

Core Principles and Instrumentation

Fundamental Physical Principles

Surface plasmon resonance occurs when photons of incident light strike a metal surface at a specific angle of incidence [1]. Under the right conditions, a portion of the light energy couples through the metal coating with electrons in the metal surface layer, setting them into oscillation [1] [3]. These coordinated electron oscillations, known as surface plasmons, generate an evanescent electric field that extends approximately 300 nanometers from the metal surface into the adjacent medium [1]. This limited range makes SPR exceptionally sensitive to minute changes at the sensor surface.

The defined SPR angle at which resonance occurs depends on the refractive index of the material near the metal surface when the light source wavelength and metal film properties remain constant [1]. When biomolecules bind to the sensor surface, they alter the local refractive index, changing the resonance conditions [1]. Detection is accomplished by measuring changes in the intensity or angle of reflected light, with the magnitude of change being directly proportional to the mass concentration of bound molecules [1] [4]. This relationship enables researchers to quantify binding events with high precision, typically with a detection limit on the order of 10 pg/mL [1].

SPR Instrumentation and Measurement

Commercial SPR instruments employ several key components to facilitate precise measurements:

- Optical System: Generates polarized light and detects changes in reflectivity

- Sensor Chip: Contains the thin gold film where molecular interactions occur

- Microfluidic System: Delieves samples in a controlled manner across the sensor surface

- Detection System: Precisely monitors changes in resonance signals over time

In SPR experiments, resonance units (RU) describe signal changes, where 1 RU is equivalent to a critical angle shift of 10⁻⁴ degrees [1]. The change in refractive index (Δnd) within a layer of thickness h can be calculated as: Δnd = (dn/dc)vol ΔΓ/h, where (dn/dc)vol represents the increase of refractive index n with the volume concentration of analyte c, and ΔΓ is the concentration of the bound target on the surface [1].

For high-throughput applications, SPR imaging (SPRI) has been developed as a modified version that enables simultaneous processing of hundreds or thousands of samples [1]. Unlike conventional SPR, SPRI measurements are performed at a constant wavelength and angle, with changes in reflected light intensity being proportional to refractive index variations across the sensor surface [1]. This approach utilizes a coherent polarized light beam to cover a larger sensing area, with reflected light captured by a charge-coupled device camera for imaging analysis [1].

Figure 1: Schematic diagram of SPR instrumentation showing key components and workflow in a typical biosensing experiment.

The Sensorgram: Interpreting SPR Data

SPR data is presented in the form of a sensorgram, which displays the binding response (in resonance units) on the y-axis against time on the x-axis [3] [4]. A typical sensorgram consists of five distinct phases that provide comprehensive information about molecular interactions:

- Baseline Phase: Running buffer flows across the sensor surface to establish a stable reference point [3] [4]

- Association Phase: Analyte is introduced, binding to the immobilized ligand and causing an increase in signal [3] [4]

- Steady-State Phase: Equilibrium is reached where association and dissociation rates are equal [3]

- Dissociation Phase: Analyte solution is replaced with buffer, allowing bound complexes to dissociate [3] [4]

- Regeneration Phase: A solution is applied to disrupt remaining interactions and restore the baseline [3] [4]

From these sensorgram phases, critical kinetic parameters can be derived, including the association rate (kₒₙ), dissociation rate (kₒff), and the equilibrium dissociation constant (Kᴅ) calculated as kₒff/kₒₙ [4]. These parameters provide a comprehensive picture of binding behavior, including interaction strength, complex stability, and binding mechanism.

Experimental Protocols for SPR Analysis

Sensor Chip Preparation and Selection

Choosing the appropriate sensor chip is fundamental to successful SPR experiments. Different chip types offer varied surface chemistries optimized for specific applications:

- CM5 Chips: Feature carboxymethylated dextran matrix for covalent immobilization, suitable for most protein studies [2] [5]

- CMD500M Chips: Commercial alternative to CM5 with comparable performance characteristics [6]

- NTA Chips: Designed for capturing His-tagged proteins via nickel-nitrilotriacetic acid chemistry [5]

- SA Chips: Coated with streptavidin for immobilizing biotinylated ligands [5]

For baseline stability comparisons between CM5 and CMD500M chips, both surfaces should be prepared following identical protocols. Prior to immobilization, sensor chips require surface preconditioning through cleaning and activation steps to ensure optimal performance and minimize baseline drift [7] [5].

Ligand Immobilization Strategies

Immobilizing the ligand to the sensor surface can be achieved through various methods, each with distinct advantages:

Covalent Immobilization via Amine Coupling

- Activate carboxymethyl groups on the sensor surface using a mixture of EDC (N-ethyl-N'-(3-dimethylaminopropyl)carbodiimide) and NHS (N-hydroxysuccinimide) [2]

- Dilute the ligand to 30 μg/mL in sodium acetate buffer (pH 5.5) [2] [8]

- Inject the ligand solution over the activated surface at a flow rate of 5 μL/min [8]

- Block remaining active groups with 1.0 M ethanolamine-HCl (pH 8.5) [2]

Affinity Capture Immobilization

- Immobilize capture molecule (e.g., streptavidin) to the sensor surface using standard amine coupling [8]

- Inject biotinylated ligand at 25 μg/mL in running buffer to capture the molecule [8]

- Apply biotin to block unoccupied binding sites on streptavidin [8]

Controlling ligand density is critical, as excessively high densities can cause steric hindrance or mass transport limitations, while low densities may yield weak signals [8] [5]. For comparative studies between CM5 and CMD500M chips, immobilization levels should be standardized across both surfaces.

Binding Experiments and Data Collection

For accurate comparison of CM5 and CMD500M performance:

- Prepare analyte concentrations in series (typically 5-8 concentrations) to cover a range below and above the expected Kᴅ value [8]

- Use HBS-EP buffer (10 mM HEPES pH 7.4, 150 mM NaCl, 3.4 mM EDTA, 0.005% surfactant P20) as the running buffer [8]

- Maintain consistent temperature (typically 25°C) throughout experiments [8]

- Employ a flow rate of 5-10 μL/min during analyte injection [8]

- Allow sufficient dissociation time (2000-6000 seconds) to monitor complex stability [8]

- Include regular blank injections (buffer alone) for double referencing to compensate for drift and bulk refractive index effects [7]

Figure 2: Experimental workflow for comparative SPR analysis of CM5 and CMD500M sensor chips.

Comparative Analysis: CM5 vs. CMD500M Sensor Chips

Performance Comparison in Binding Studies

Recent comparative studies have evaluated the performance characteristics of original Biacore CM5 chips and their analog CMD500M chips under identical experimental conditions. In one comprehensive study, Protein A was immobilized on both chip types as a molecular ligand, with IgG antibody used as the analyte [6]. The binding interactions were analyzed using various concentrations of antibodies to determine kinetic parameters.

Table 1: Comparative kinetic analysis of CM5 and CMD500M sensor chips

| Parameter | CM5 Chip | CMD500M Chip | Difference |

|---|---|---|---|

| Association Rate Constant (kₒₙ) | Baseline | +18% variation | 18% |

| Dissociation Rate Constant (kₒff) | Baseline | +10% variation | 10% |

| Equilibrium Dissociation Constant (Kᴅ) | Baseline | +9% variation | 9% |

| Binding Response | Comparable | Comparable | Minimal |

| Baseline Stability | Similar performance | Similar performance | Comparable |

The results demonstrated that both chip types produced similar binding responses and baseline stability, with differences in kinetic constants of less than 20% [6]. This level of variation falls within acceptable ranges for most biosensing applications, confirming the interchangeability of these surfaces for standard molecular interaction analysis.

Baseline Stability Assessment

Baseline stability is a critical factor in SPR biosensing, as drift can compromise data quality and kinetic parameter accuracy. Several factors contribute to baseline performance in CM5 and CMD500M chips:

Causes of Baseline Drift

- Surface Rehydration: Newly docked sensor chips require equilibration time [7]

- Buffer Incompatibility: Buffer changes can cause refractive index mismatches [7] [5]

- Residual Contamination: Incomplete surface regeneration leaves bound material [7]

- Flow Rate Fluctuations: Sudden flow changes affect surface equilibrium [7]

Minimizing Drift Strategies

- Prime the system thoroughly after buffer changes [7]

- Include start-up cycles with buffer injections before sample analysis [7]

- Ensure proper surface regeneration between binding cycles [5]

- Maintain consistent temperature and flow conditions [5]

- Use double referencing with blank injections spaced throughout experiments [7]

Both CM5 and CMD500M chips demonstrate similar baseline characteristics when properly handled, with drift rates becoming comparable after adequate system equilibration [6] [7].

Essential Reagents and Materials

Successful SPR experiments require carefully selected reagents and materials to ensure reproducible results. The following table outlines key components for comparative SPR studies:

Table 2: Essential research reagents and materials for SPR experiments

| Reagent/Material | Function | Example Products |

|---|---|---|

| Sensor Chips | Platform for immobilization and detection | CM5 (Cytiva), CMD500M (XanTec) [6] |

| Running Buffer | Maintains pH and ionic strength during analysis | HBS-EP, HBS-N, PBS [2] [8] |

| Coupling Reagents | Activates surface for ligand immobilization | EDC, NHS [2] |

| Regeneration Solutions | Removes bound analyte without damaging ligand | Glycine-HCl (pH 1.5-3.0), NaOH [2] |

| Blocking Agents | Reduces non-specific binding | Ethanolamine, BSA [2] [5] |

| Capture Molecules | Enables oriented immobilization | Streptavidin, Protein A [8] |

Troubleshooting and Optimization

Addressing Common SPR Challenges

Non-Specific Binding

- Use surface blocking agents (ethanolamine, casein, BSA) to occupy active sites [5]

- Optimize buffer composition with additives like Tween-20 to reduce hydrophobic interactions [5]

- Employ reference surfaces to identify and subtract non-specific signals [8]

- Select sensor chips with surface chemistries tailored to specific analyte properties [5]

Low Signal Intensity

- Optimize ligand immobilization density to balance signal strength and accessibility [5]

- Improve immobilization efficiency by adjusting coupling buffer pH and composition [5]

- Consider high-sensitivity chips (CM5, PlexChip) for weak interactions or low-abundance analytes [5]

- Increase analyte concentration while monitoring for mass transport limitations [5]

Poor Reproducibility

- Standardize surface activation and ligand immobilization protocols [5]

- Include control samples with irrelevant ligands to monitor specificity [5]

- Pre-condition sensor chips with buffer cycles to stabilize surfaces [7] [5]

- Maintain consistent environmental conditions (temperature, humidity) [5]

Optimization Strategies for Baseline Stability

Achieving stable baselines is particularly important for comparative studies between different sensor chips:

- Buffer Management: Prepare fresh buffers daily, filter through 0.22 μM membranes, and degas before use to minimize air spikes [7]

- System Equilibration: Flow running buffer over newly docked sensor surfaces until stable (may require extended time or overnight flow) [7]

- Start-up Cycles: Incorporate 3+ start-up cycles with buffer injections and regeneration before data collection to stabilize surfaces [7]

- Regular Calibration: Ensure instrument components (especially the integrated fluidic cartridge) are properly calibrated and maintained [5]

Surface Plasmon Resonance biosensing represents a versatile and powerful technology for studying molecular interactions in real-time without labels. The comparative analysis between CM5 and CMD500M sensor chips demonstrates comparable performance in binding studies and baseline stability, with kinetic parameter variations of less than 20% [6]. This confirms the interchangeability of these surfaces for most research applications, providing researchers with flexibility in consumables selection.

Successful SPR experiments require careful attention to experimental design, including appropriate sensor chip selection, optimized immobilization strategies, proper buffer preparation, and systematic troubleshooting approaches. Following standardized protocols for comparative assessments ensures reliable data collection and interpretation. As SPR technology continues to evolve, maintaining rigorous experimental standards will remain essential for generating high-quality binding data that advances scientific understanding and drug development efforts.

Surface Plasmon Resonance (SPR) is a label-free optical biosensing technique that enables researchers to measure molecular interactions in real-time by detecting changes in the refractive index near a sensor surface [3]. The foundational output of an SPR experiment is the sensorgram, a plot of response (measured in Resonance Units, RU) against time, which provides a visual representation of the entire binding event [3]. The initial phase of this sensorgram, known as the baseline, is established before the analyte is introduced and represents the signal from the immobilized ligand in a stable state with buffer flowing over it [3]. A stable baseline is not merely a procedural formality; it is the essential cornerstone for generating reliable, interpretable kinetic data. Instabilities in the baseline, manifested as drift or excessive noise, can obscure the true binding signal, compromise the accuracy of calculated kinetic parameters (kon, koff, KD), and ultimately lead to erroneous scientific conclusions.

The stability of this baseline is profoundly influenced by the sensor chip itself. Different sensor chips, with variations in their polymer matrix, hydrogel thickness, density, and surface chemistry, can exhibit distinct performance characteristics. This guide provides an objective, data-driven comparison of baseline stability and overall performance between a longstanding industry standard, the Cytiva Biacore CM5 chip, and a commercially available analogue, the XanTec CMD500M chip.

Comparative Product Analysis: CM5 vs. CMD500M

The CM5 sensor chip from Cytiva is one of the most widely used SPR chips in life science research. Its surface consists of a carboxymethylated dextran matrix that forms a hydrogel, providing a hydrophilic environment for ligand immobilization and minimizing non-specific binding [2]. However, users of Biacore SPR biosensors have recently faced challenges due to "sanctions restrictions on the purchase of consumables (primarily optical chips)" [6]. This has driven the need for commercially available, functionally equivalent analogues that can ensure the continuity of research.

The XanTec CMD500M is one such analogue, explicitly designed to be compatible with Biacore series instruments. Like the CM5, it features a carboxymethyldextran-based hydrogel, which is a linear polycarboxylate or carboxymethyldextran polymer [9]. According to XanTec's selection guide, the CMD500M, with its ~500 nm thick hydrogel and medium density, is recommended for interactions involving protein-peptide or protein-small molecule binding, a common application in drug discovery [9].

Table 1: Key Specifications of CM5 and CMD500M Sensor Chips

| Feature | Cytiva Biacore CM5 | XanTec CMD500M |

|---|---|---|

| Polymer Matrix | Carboxymethylated dextran | Carboxymethyldextran (CMD) |

| Hydrogel Thickness | ~100 nm (for CM5) [9] | ~500 nm (for CMD500M) [9] |

| Recommended Applications | Broad range; standard for protein-protein interactions [2] | Protein-peptide/small molecule interactions [9] |

| Immobilization Chemistry | NHS/EDC amine coupling standard [2] | NHS/EDC amine coupling compatible |

| Instrument Compatibility | Biacore instruments | Biacore series S compatible [9] |

Experimental Comparison and Performance Data

A direct, comparative study of the original Biacore CM5 chip and the XanTec CMD500M analogue was conducted by researchers at the Institute of Biomedical Chemistry in Moscow to evaluate their interchangeability for rigorous interaction analysis [6].

Experimental Protocol

The experimental methodology was designed to mirror a common SPR application and was applied identically to both chip types [6]:

- Ligand Immobilization: Protein A, a protein frequently used to immobilize antibodies, was immobilized on both the CM5 and CMD500M sensor chips.

- Analyte Binding: A solution of IgG antibody was used as the analyte and injected over the chip surfaces at various concentrations.

- Data Collection: Sensorgrams were recorded in real-time on a Biacore X100 SPR biosensor, capturing the entire association and dissociation process.

- Kinetic Analysis: The resulting sensorgrams were analyzed using a 1:1 (Langmuir) binding model to calculate the kinetic rate constants for association (kon) and dissociation (koff), as well as the equilibrium dissociation constant (Kd).

Quantitative Results and Stability Assessment

The research demonstrated that both chips produced high-quality data with very similar binding kinetics, indicating that the CMD500M reliably replicates the core functionality of the CM5 chip [6].

Table 2: Comparative Kinetic Parameters from CM5 vs. CMD500M Study

| Kinetic Parameter | CM5 Chip | CMD500M Chip | Percentage Difference |

|---|---|---|---|

| Association Rate (kon) | Baseline | Comparable Value | +18% |

| Dissociation Rate (koff) | Baseline | Comparable Value | +10% |

| Equilibrium Constant (Kd) | Baseline | Comparable Value | +9% |

The observed differences in kinetic constants (9-18%) are well within an acceptable range for biosensor studies and confirm that the CMD500M chip is a functionally equivalent alternative to the original CM5 [6]. The successful application of the standard 1:1 binding model and the low variability in calculated constants strongly imply that both chips were capable of generating a stable baseline and clean sensorgrams, free from significant drift or noise that would otherwise complicate kinetic analysis.

The Scientist's Toolkit: Essential Research Reagents

Successful SPR experiments depend on a suite of specialized reagents and materials. The following table outlines key solutions required for the immobilization and analysis protocols similar to the comparative study.

Table 3: Essential Research Reagent Solutions for SPR

| Reagent/Solution | Function & Application | Example from Literature |

|---|---|---|

| HBS-EP Buffer (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.005% P20) | Standard running buffer; maintains pH and ionic strength, surfactant P20 minimizes non-specific binding. | Used as the working buffer in surface characterization studies [8]. |

| NHS/EDC Reagents | Activates carboxyl groups on dextran chips for covalent amine coupling of protein ligands. | Standard amine coupling protocol for CM5 chips [2]. |

| Ethanolamine HCl | Blocks remaining activated ester groups on the sensor surface after ligand immobilization. | Used post-immobilization to deactivate excess sites [2]. |

| Sodium Acetate Buffers (low pH) | Serves as the immobilization buffer; optimal pH is selected based on the isoelectric point (pI) of the protein ligand. | Used at pH 4.0 - 5.5 for ligand immobilization [2]. |

| Regeneration Solutions (e.g., Glycine-HCl, NaOH) | Removes tightly bound analyte from the immobilized ligand without damaging it, allowing for chip re-use. | Solutions like 10 mM glycine pH 2.0-3.0 or 50 mM NaOH are common [2]. |

SPR Workflow and Data Analysis Visualization

The following diagram illustrates the critical steps of an SPR experiment, from system preparation to data interpretation, highlighting where baseline stability is paramount.

The sensorgram is the primary output of an SPR experiment. Understanding its phases is crucial for diagnosing assay quality and kinetic analysis.

The experimental data clearly demonstrates that the XanTec CMD500M sensor chip is a functionally equivalent and interchangeable alternative to the original Cytiva CM5 chip [6]. The minor differences in measured kinetic constants are not statistically significant in the context of biosensor analysis and highly unlikely to impact biological conclusions. For researchers facing supply chain constraints, the CMD500M provides a viable solution without compromising data quality.

The choice between a CM5 and a CMD500M, or any sensor chip, should ultimately be guided by the specific experimental needs. The CMD500M, with its thicker hydrogel (500 nm), may offer an advantage for capturing small molecules due to a larger surface volume, which can increase the maximum binding capacity (Rmax) and improve the signal-to-noise ratio for low molecular weight analytes [9]. The CM5, with its thinner hydrogel (~100 nm), might be preferred for analyzing very large analytes like viruses or cells to minimize mass transport limitations [9].

In conclusion, baseline stability is a non-negotiable prerequisite for reliable SPR analysis. This comparison confirms that both the CM5 and CMD500M sensor chips are capable of providing the stable performance required for rigorous interaction studies. Scientists can select the CMD500M with confidence, ensuring their critical research in drug discovery and molecular interaction analysis continues unimpeded.

Consequences of Baseline Drift on Kinetic and Affinity Measurements

Surface Plasmon Resonance (SPR) biosensors have become indispensable tools for characterizing biomolecular interactions in real-time, providing critical data on binding kinetics and affinity. The stability of the SPR baseline signal is a fundamental prerequisite for obtaining accurate and reliable kinetic parameters. This guide objectively compares the baseline stability and performance of the classic Biacore CM5 sensor chip and its analogue, the XanTec CMD500M, within the context of ongoing research on SPR baseline stability. Supported by experimental data, we demonstrate that while both chips deliver highly comparable kinetic and affinity data, their specific handling and equilibration requirements can significantly influence baseline drift, thereby directly impacting the quality of the derived constants for association (k~on~), dissociation (k~off~), and equilibrium dissociation (K~D~).

In SPR biosensing, a sensorgram is the primary data output, plotting the SPR response (in Resonance Units, RU) against time [4]. A stable baseline—the flat portion of the sensorgram before analyte injection—is the foundation upon which all binding data is interpreted. Baseline drift, a gradual increase or decrease of this signal, is a common phenomenon often indicative of a non-optimally equilibrated sensor surface [7]. This drift can originate from several sources, including the rehydration of a newly docked chip, wash-out of immobilization chemicals, or a slow adjustment of the immobilized ligand to the flow buffer [7].

The consequences of unaddressed baseline drift are profound for kinetic and affinity analysis. Modern SPR software calculates kinetic parameters by fitting mathematical models to the association and dissociation phases of the sensorgram. A drifting baseline can lead to significant errors in the fitted values of k~on~ and k~off~, which in turn distorts the calculation of the overall binding affinity (K~D~ = k~off~/k~on~) [4]. Therefore, selecting a sensor chip with inherent stability and understanding its equilibration needs is a critical first step in experimental design.

Comparative Analysis: CM5 vs. CMD500M

A direct comparative study of the original Biacore CM5 chip and its analog, the XanTec CMD500M, provides valuable insights into their performance parity. The study, which immobilized Protein A on both chips and used IgG as an analyte, found the chips to be functionally interchangeable for this application [6].

Table 1: Quantitative Comparison of Kinetic Parameters from CM5 and CMD500M

| Parameter | Biacore CM5 | XanTec CMD500M | Percentage Difference |

|---|---|---|---|

| Association Constant (k~on~) | Reference Value | Comparable Value | 18% |

| Dissociation Constant (k~off~) | Reference Value | Comparable Value | 10% |

| Equilibrium Dissociation Constant (K~D~) | Reference Value | Comparable Value | 9% |

Source: Adapted from Gnedenko et al. (2024) [6].

The minor differences shown in Table 1 fall within an acceptable range for most applications, confirming the CMD500M as a viable alternative to the CM5. The underlying base coating of both chips is a carboxymethylated (CM) dextran hydrogel, which provides a bioinert matrix that minimizes non-specific binding and serves as a versatile platform for various immobilization chemistries [6] [10]. This similarity in core architecture is a key reason for their comparable performance.

The Source and Impact of Baseline Drift

Baseline drift is often most pronounced directly after docking a new sensor chip or following the immobilization of the ligand [7]. This is frequently due to the rehydration of the sensor surface and the gradual wash-out of chemicals used during the immobilization procedure. The drift is a physical signal reflecting a changing environment on the chip surface, which the instrument interprets as a binding or dissociation event. If this drift is not accounted for, it becomes integrated into the curve-fitting algorithm for kinetic analysis.

For instance, an upward drift during the dissociation phase could make the analyte appear to be dissociating more slowly than it truly is, leading to an underestimation of k~off~. Since K~D~ is directly proportional to k~off~, this would result in an incorrectly calculated, higher-affinity interaction (lower K~D~) [7] [4]. The impact is similarly detrimental during the association phase, where drift can distort the apparent association rate.

Equilibration and Drift Mitigation Strategies

The process of mitigating baseline drift is universally crucial, regardless of the specific CM-type chip used. The following experimental workflow outlines the standard procedures for establishing a stable baseline.

The most critical step in combating drift is adequate surface equilibration. This involves flowing the running buffer over the sensor surface until a stable baseline is achieved. As highlighted in the troubleshooting guide, "It can be necessary to run the running buffer overnight to equilibrate the surfaces" [7]. Furthermore, incorporating start-up cycles (injecting buffer instead of analyte at the beginning of an experiment) and blank injections throughout the run is recommended to stabilize the system and provide data for a processing technique called double referencing, which compensates for drift and bulk effect [7].

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for SPR Experiments

| Item | Function in SPR Experiment |

|---|---|

| CM5 / CMD500M Sensor Chip | The core platform with a carboxymethyl dextran matrix for ligand immobilization. |

| HBS-EP Buffer | A common running buffer (HEPES, NaCl, EDTA, surfactant P20) that maintains pH and ionic strength while reducing non-specific binding. |

| NHS/EDC Reagents | Used for covalent amine coupling to activate the carboxyl groups on the chip surface for ligand immobilization. |

| Ethanolamine | Used to deactivate and block remaining active esters on the chip surface after covalent immobilization. |

| Regeneration Solutions | Low pH buffers (e.g., Glycine HCl) or high-salt solutions used to remove bound analyte without damaging the immobilized ligand. |

| Protein A | A common capture ligand for immobilizing antibodies via their Fc region, ensuring proper orientation. |

Advanced Considerations for Membrane Proteins and Small Molecules

While the CM5 and CMD500M are workhorse chips for soluble proteins, studying challenging targets like membrane proteins requires specialized approaches. The capture-stabilize method has been successfully employed for G-protein-coupled receptors (GPCRs) [11]. This technique involves capturing a His-tagged membrane protein (e.g., CXCR5) on an NTA chip, followed by limited cross-linking to stabilize it on the surface. This creates a robust surface that can withstand regeneration steps, enabling reliable kinetic analysis of antibodies binding to the native receptor [11].

For small molecule analysis, mass limitations become a significant factor. The maximum response (R~max~) is proportional to the molecular weight of the analyte. Achieving a sufficient signal for accurate kinetics with small molecules often requires immobilizing very high levels of ligand, which can lead to crowding and steric hindrance [12]. In such cases, using specialized high-capacity chips or alternative strategies, such as immobilizing a protein fragment that contains the small molecule binding site, may be necessary to improve resolution [12].

The choice between the Biacore CM5 and XanTec CMD500M sensor chips need not be a significant variable in experimental outcomes for standard protein-protein interactions, as their kinetic and affinity measurements are highly comparable. The primary factor influencing data quality, particularly for precise kinetic analysis, is the management of baseline stability. Researchers must adhere to rigorous buffer preparation, allow for sufficient system and surface equilibration, and employ referencing techniques to mitigate drift. For more complex targets like membrane proteins or small molecules, moving beyond standard chips to specialized surfaces and immobilization strategies is often required to obtain biologically relevant binding data. A meticulous approach to surface preparation and selection is paramount for generating accurate kinetic and affinity constants.

Surface Plasmon Resonance (SPR) biosensing has revolutionized the study of molecular interactions in drug discovery and basic research by enabling real-time, label-free monitoring of binding events. [13] [14] At the heart of many SPR experiments lies the carboxymethyl dextran hydrogel, a three-dimensional matrix that serves as the interface for immobilizing biological molecules. [15] [6] This hydrogel matrix creates a hydrophilic environment that reduces non-specific binding while providing carboxyl groups for the covalent attachment of ligands, making it the industry standard for over two decades. [15] [16] The CM5 chip, introduced by Biacore (now Cytiva), is one of the most recognized and widely used sensor chips of this type. However, the evolution of SPR technology and recent supply challenges have spurred the development of commercially available analogues, with XanTec's CMD500M emerging as a direct and functionally equivalent alternative. [6] This guide provides an objective comparison of these two chips, focusing on their performance, experimental applications, and implications for research continuity and planning, particularly within the context of SPR baseline stability.

Technical Specifications and Design Philosophy

The CM5 and CMD500M sensor chips share a fundamental design principle: a carboxymethylated dextran hydrogel layer covalently attached to a gold film. [6] [10] The "500" in CMD500M denotes a 500 kDa carboxymethylated dextran hydrogel, which forms the capture layer. [15] This specific molecular weight is central to the chip's performance, creating a defined environment for ligand immobilization and analyte interaction.

Table 1: Core Technical Specifications of CM5 and CMD500M Sensor Chips

| Feature | Biacore CM5 | XanTec CMD500M |

|---|---|---|

| Base Matrix | Carboxymethyl dextran | Carboxymethyl dextran |

| Dextran Chain Mass | Not specified in results | 500 kDa [15] |

| Surface Geometry | Three-dimensional (3D) hydrogel | Three-dimensional (3D) hydrogel [15] |

| Key Functionality | Carboxyl groups for covalent coupling | Carboxyl groups for covalent coupling [10] |

| Primary Immobilization | Amine coupling | Amine coupling |

| Common Applications | Protein-protein interactions, kinetic studies | Small molecule analysis, kinetic studies [15] |

While the core chemistry is similar, differences in manufacturing and potentially in the underlying grafting layer can lead to variations in practical performance, which are explored in the following sections. [15] [6]

Comparative Performance and Experimental Data

A direct comparative study published in 2024 provides the most robust, head-to-head experimental data on the performance of the CM5 and CMD500M chips. Researchers conducted a side-by-side interaction analysis using a Biacore X100 instrument, immobilizing Protein A on both chips and using IgG as the analyte to determine kinetic constants. [6]

Table 2: Experimental Kinetic Data from Comparative Study [6]

| Performance Parameter | Biacore CM5 | XanTec CMD500M | Observed Difference |

|---|---|---|---|

| Association Rate Constant (kon) | Reference Value | Comparable | +18% |

| Dissociation Rate Constant (koff) | Reference Value | Comparable | +10% |

| Equilibrium Dissociation Constant (KD) | Reference Value | Comparable | +9% |

The study concluded that the differences in kinetic constants were minor, confirming the functional interchangeability of the original CM5 and the CMD500M analogue for this type of protein-protein interaction. [6] For researchers, this means that switching from CM5 to CMD500M is unlikely to necessitate major protocol changes or invalidate historical data, a critical consideration for ongoing research projects.

Application in Small Molecule Analysis

The CMD500M chip has been specifically highlighted for its utility in challenging applications like small molecule analysis. The combination of the 2SPR Dual Channel SPR system and the XanTec CMD500m sensor chip has demonstrated excellent results for studying interactions involving very low molecular weight analytes, such as methanesulfonamide (95 Da) and 4-carboxybenzenesulfonamide (201 Da) with the enzyme carbonic anhydrase. [15] This underscores the chip's high sensitivity and low noise, which are essential for detecting the minimal refractive index changes caused by small molecule binding. [15]

The Scientist's Toolkit: Essential Reagents and Materials

Successful SPR experiments using CM5 or CMD500M chips require a suite of specialized reagents and materials. The following table details the key components for a standard amine coupling procedure, as exemplified in the search results. [17]

Table 3: Key Research Reagent Solutions for Carboxymethyl Dextran Chip Experiments

| Reagent/Material | Function | Example from Protocol |

|---|---|---|

| Sensor Chip (CM5/CMD500M) | Platform with hydrogel matrix for ligand immobilization. | Sensor Chip CM5 [17] |

| Amine Coupling Kit | Contains chemicals (EDC, NHS) to activate carboxyl groups on the dextran matrix for ligand attachment. | Amine Coupling Kit (GE Healthcare) [17] |

| Immobilization Buffers | Low-pH buffers (e.g., sodium acetate) used to optimize ligand pre-concentration on the chip surface. | 10 mM sodium acetate, pH 4.0 & 4.5 [17] |

| Running Buffer | Stable-buffered solution (e.g., HBS-EP) used to maintain pH and ionic strength during analyte injection. | HBS-EP [17] |

| Regeneration Solution | A solution that disrupts the ligand-analyte interaction without damaging the ligand, allowing chip re-use. | 10 mM NaOH, 10 mM EDTA [17] |

Experimental Workflow for Immobilization and Analysis

A generalized workflow for conducting an experiment with CM5 or CMD500M chips is outlined below. This workflow is synthesized from protocols used for studying GPCR domain interactions [17] and small molecule inhibitors [15].

Diagram 1: Generalized SPR experimental workflow using carboxymethyl dextran sensor chips.

Detailed Methodological Notes

- Ligand Immobilization: The core of the assay is activating the carboxymethyl dextran surface with a mixture of EDC (N-ethyl-N'-(dimethylaminopropyl)carbodiimide) and NHS (N-hydroxysuccinimide) to form reactive esters. The ligand is then injected in a low-pH immobilization buffer (e.g., sodium acetate, pH 4.0-4.5) to promote electrostatic pre-concentration near the surface, leading to efficient covalent coupling. [17]

- Regeneration Scouting: Identifying an effective regeneration solution is critical for re-using the sensor chip. This involves testing solutions that can break the specific ligand-analyte interaction without denaturing the immobilized ligand. Common agents include low-pH buffers (e.g., glycine-HCl), bases (e.g., NaOH), or chelators (e.g., EDTA). [17] [10]

The objective comparison of the Biacore CM5 and XanTec CMD500M sensor chips reveals a high degree of functional equivalence. Independent research confirms that the differences in key performance metrics, such as association rate, dissociation rate, and binding affinity, are minimal, at 18%, 10%, and 9% respectively. [6] This data supports the strategic interchangeability of these platforms, offering researchers a viable path to maintaining experimental continuity in the face of supply chain constraints.

The CMD500M chip has also demonstrated excellent performance in specific, demanding applications such as small molecule analysis, showcasing low noise and high sensitivity. [15] For the research community, this equivalence empowers continued innovation in drug discovery and basic research, ensuring that the foundational tool of SPR biosensing remains accessible and reliable.

Methodologies for Assessing SPR Chip Performance and Stability

Optimal Immobilization Strategies for CM5 and CMD500M Chips

Surface Plasmon Resonance (SPR) biosensors have become indispensable tools in life science research and drug discovery for characterizing biomolecular interactions in real-time without labels. The sensor chip is the core of any SPR system, and its selection and proper use are critical for obtaining high-quality, reliable data. The Biacore CM5 chip, with its carboxymethylated dextran matrix, has long been the industry standard. However, recent geopolitical constraints have created significant challenges for researchers relying on original equipment manufacturer consumables, making the exploration of scientifically validated alternatives an urgent necessity [6]. The CMD500M chip from XanTec has emerged as a promising alternative, claiming full compatibility with Biacore systems and comparable performance characteristics. This comparison guide provides an objective evaluation of both chip types, focusing on immobilization strategies and performance metrics, to empower researchers in making evidence-based decisions for their specific experimental needs.

Technical Specifications and Design Principles

The CM5 and CMD500M chips share fundamental design principles while exhibiting subtle differences that may influence experimental outcomes. Both feature a gold film surface modified with a carboxymethylated dextran hydrogel matrix that provides a biocompatible environment for ligand immobilization and biomolecular interactions. This hydrogel matrix serves to minimize non-specific binding while creating a three-dimensional environment that increases ligand loading capacity compared to two-dimensional surfaces [9].

The CM5 chip employs a hydrogel layer of approximately 100 nm thickness with medium matrix density, making it suitable for a broad range of applications from small molecule studies to large complex formations. The CMD500M, as indicated by its nomenclature, features a approximately 500 nm thick carboxymethylated dextran hydrogel coupled with a proprietary grafting layer designed to enhance stability and performance, particularly with small molecule analytes [15]. According to manufacturer specifications, the CMD500M is specifically recommended for protein-peptide and protein-small molecule interactions due to its dense hydrogel structure with high binding capacity [9].

Both chips utilize the same fundamental chemistry for ligand immobilization, primarily relying on amine coupling through activation of surface carboxyl groups with a mixture of N-hydroxysuccinimide (NHS) and N-ethyl-N'-(3-dimethylaminopropyl)carbodiimide (EDC). This compatibility ensures that established protocols for CM5 can be directly transferred to the CMD500M platform without significant modification [6].

Table 1: Technical Specifications of CM5 and CMD500M Sensor Chips

| Parameter | Biacore CM5 | XanTec CMD500M |

|---|---|---|

| Hydrogel Matrix | Carboxymethylated dextran | Carboxymethylated dextran with proprietary grafting layer |

| Hydrogel Thickness | ~100 nm | ~500 nm |

| Recommended Applications | Broad range: proteins, nucleic acids, small molecules, particles | Protein-peptide and protein-small molecule interactions |

| Immobilization Chemistry | Standard amine coupling (NHS/EDC) | Standard amine coupling (NHS/EDC) |

| Compatibility | Biacore systems | Biacore-compatible systems |

Comparative Experimental Analysis

Direct Performance Comparison Study

A comprehensive comparative study published in 2024 directly addressed the interchangeability of CM5 and CMD500M chips using a well-established model system. Researchers immobilized Protein A on both chip types and evaluated the binding interactions with IgG antibodies at varying concentrations. The experimental design allowed for direct comparison of kinetic parameters including association rate (k~on~), dissociation rate (k~off~), and equilibrium dissociation constant (K~D~) [6].

The results demonstrated remarkably similar binding characteristics between the two platforms. The calculated differences in kinetic parameters were minimal: 18% for k~on~, 10% for k~off~, and only 9% for the overall binding affinity (K~D~). These minor variations fall within acceptable experimental error ranges for most SPR applications, strongly supporting the functional equivalence of both chips for antibody-protein A interactions [6].

Table 2: Kinetic Parameters from Comparative CM5 vs. CMD500M Study

| Kinetic Parameter | CM5 Chip | CMD500M Chip | Percent Difference |

|---|---|---|---|

| Association Rate Constant (k~on~) | Reference value | Comparable value | 18% |

| Dissociation Rate Constant (k~off~) | Reference value | Comparable value | 10% |

| Equilibrium Dissociation Constant (K~D~) | Reference value | Comparable value | 9% |

Small Molecule Binding Applications

The CMD500M chip has demonstrated exceptional performance in small molecule analysis, a challenging application area requiring high sensitivity. In a study investigating inhibitors of carbonic anhydrase, the CMD500M chip successfully detected interactions with methanesulfonamide (95 Da) and 4-carboxybenzenesulfonamide (201 Da), showcasing its capability for very low molecular weight analytes [15]. The dense hydrogel matrix of the CMD500M provides increased surface area and binding capacity beneficial for detecting small molecule binding events that generate minimal SPR response signals.

Similarly, research on synthetic cannabinoids (SCs) further validated the CMD500M's performance in receptor-ligand studies. The chip effectively immobilized CB1 receptor proteins through standard amine coupling, achieving approximately 2500 response units (RU) immobilization level, which proved sufficient for assessing the affinity of ten different SC compounds with molecular weights typically ranging from 300-500 Da [18]. The resulting affinity rankings and structure-activity relationships aligned with literature values obtained through traditional methods, confirming the reliability of data generated using the CMD500M platform.

Immobilization Methodologies

Standard Amine Coupling Protocol

The following standardized protocol applies to both CM5 and CMD500M chips for immobilization of protein ligands:

Surface Activation: Inject a 1:1 mixture of 0.4 M EDC and 0.1 M NHS over the dextran surface for 7 minutes at a flow rate of 5-10 μL/min. This activation step typically generates an increase of 100-200 RU [18].

Ligand Immobilization: Dilute the protein ligand to 30-50 μg/mL in sodium acetate buffer (pH 5.5 is standard, but pH should be optimized 0.5-1.0 unit below the protein's pI). Inject over the activated surface for 10-15 minutes at 5 μL/min to achieve desired immobilization level [8].

Surface Blocking: Inject 1 M ethanolamine-HCl (pH 8.5) for 7 minutes to deactivate remaining activated carboxyl groups and minimize non-specific binding [18].

Stabilization: Run 2-3 buffer injections to establish a stable baseline before beginning binding experiments.

For the CMD500M chip specifically, the immobilization process follows the same three-phase pattern observed with CM5 chips: initial activation confirmed by 100-200 RU increase, ligand coupling evidenced by substantial RU increase, and final blocking with ethanolamine hydrochloride resulting in stable baseline stabilization [18].

Specialized Immobilization Strategies

Beyond standard amine coupling, both chips support various immobilization approaches:

Affinity Capture: For studying antibody-antigen interactions, Protein A or Protein G can be immobilized via amine coupling, followed by antibody capture. This approach offers oriented immobilization and regeneration capabilities. The CMD500M has demonstrated excellent performance with Protein A immobilization at levels sufficient for quantitative antibody binding studies [6].

Strepavidin-Biotin System: For DNA and RNA studies, strepavidin-modified surfaces can be used to capture biotinylated nucleic acids. The CMD500M's thicker hydrogel provides higher binding capacity for such applications, particularly beneficial for studying small molecule interactions with immobilized DNA structures [19].

Membrane Protein Studies: Both chips can be adapted for membrane protein studies using L1 chips or HPA chips as references, though these specialized applications may require chip-specific optimization beyond the scope of this guide [13].

Experimental Design and Optimization Strategies

Immobilization Level Optimization

The immobilization level of the ligand significantly impacts the quality of SPR data. For kinetic studies, lower immobilization levels (50-100 RU for high molecular weight analytes; 500-1000 RU for small molecules) are recommended to minimize mass transport effects and rebinding artifacts [8]. For the CMD500M chip with its higher capacity matrix, slightly higher immobilization levels may be acceptable while maintaining data quality.

For small molecule studies using CMD500M, immobilization levels of 2500-5000 RU for the protein target have proven effective for detecting interactions with compounds below 500 Da molecular weight [15] [18]. The increased matrix thickness provides enhanced binding capacity without significantly compromising kinetic accuracy.

Reference Surface Preparation

Proper reference surface preparation is critical for both chips to account for non-specific binding, bulk refractive index changes, and matrix effects. For direct immobilization, a reference flow cell should be activated and blocked without ligand immobilization. For capture-based approaches, the reference surface should contain the capture molecule (e.g., Protein A) but without the specific ligand [8].

The continuous affinity/kinetic rate distribution analysis approach has proven valuable in assessing surface heterogeneity resulting from different immobilization strategies. This method can detect subtle differences in binding site uniformity between different chip types and immobilization approaches [8].

Research Reagent Solutions

Table 3: Essential Research Reagents for CM5 and CMD500M Immobilization

| Reagent | Function | Application Notes |

|---|---|---|

| NHS/EDC Mixture | Activates carboxyl groups on dextran matrix for amine coupling | Standard concentration: 0.4 M EDC/0.1 M NHS; 7-minute injection |

| Ethanolamine-HCl | Blocks remaining activated groups after immobilization | Typically 1 M, pH 8.5; quenches unreacted NHS esters |

| Sodium Acetate Buffer | Dilution buffer for ligand during immobilization | pH 4.0-5.5; should be 0.5-1.0 pH units below protein pI |

| HBS-EP Buffer | Running buffer for most applications | 10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.005% surfactant P20; pH 7.4 |

| Protein A | Affinity capture ligand for antibody immobilization | Provides oriented immobilization; suitable for both chips |

| Strepavidin | Capture molecule for biotinylated ligands | High-affinity capture for DNA, RNA, proteins |

| Regeneration Solutions | Removes bound analyte without damaging ligand | Varies by application (e.g., glycine pH 2.0-3.0 for antibodies) |

The experimental evidence demonstrates that the CMD500M chip represents a scientifically valid alternative to the Biacore CM5, with comparable performance in kinetic analysis and binding studies. The minimal differences observed in direct comparison studies (9-18% variance in kinetic parameters) fall within acceptable ranges for most applications [6]. The CMD500M shows particular strength in small molecule interaction studies due to its thicker hydrogel matrix that provides enhanced binding capacity [15]. Researchers facing supply chain challenges can transition to the CMD500M platform with confidence, using established CM5 protocols with minimal modification. Both chips respond identically to standard immobilization chemistries and yield thermodynamically equivalent interaction data, supporting their interchangeability for routine SPR applications.

Figure 1: Experimental workflow for CM5 and CMD500M chip utilization. Both chips follow identical immobilization protocols but benefit from application-specific optimization. The workflow culminates in data analysis confirming their interchangeable performance with minimal differences in kinetic parameters.

Designing a Controlled Experiment for Direct Chip Comparison

Surface Plasmon Resonance (SPR) biosensors have become a cornerstone technique for studying biomolecular interactions in real-time and without labels [20]. The sensor chip is the heart of any SPR system, and its properties—including surface chemistry, matrix structure, and immobilization approach—directly influence the quality and reliability of the generated kinetic and affinity data [8] [21]. Within the broad landscape of available sensor chips, the Biacore CM5 chip, with its carboxymethylated dextran matrix, has long been a versatile and widely adopted standard for diverse interaction studies [21] [22].

However, the need for accessible alternatives has brought chips like the XanTec CMD500M into focus. A controlled, direct comparison under standardized experimental conditions is essential for researchers to make informed decisions about chip selection, ensuring data quality and assay robustness. This guide provides a framework for such a comparison, centered on a formal study that objectively evaluates the performance of the CM5 chip against its analogue, the CMD500M, with a specific emphasis on baseline stability and its implications for data integrity [6].

Chip Specifications and Comparison

The foundation of a valid comparison is a clear understanding of the technical specifications of the chips being evaluated. The CM5 sensor chip features a three-dimensional carboxymethylated dextran hydrogel layer that facilitates ligand immobilization and provides a low-noise, non-fouling environment [21]. The CMD500M is presented as a direct analogue, also employing a bioinert carboxymethyl dextran (CMD) matrix, which suggests a design goal of functional equivalence and interoperability [6] [10].

The table below summarizes the key characteristics of both chips based on manufacturer specifications and independent research:

| Feature | Biacore CM5 | XanTec CMD500M |

|---|---|---|

| Base Coating | Carboxymethylated dextran hydrogel [21] | Bioinert carboxymethyl dextran (CMD) [10] |

| Surface Type | 3D matrix [21] | 3D matrix [10] |

| Key Application | General-purpose; protein-protein interactions, antibody-antigen studies [21] [22] | Designed as a functional analogue to the CM5 [6] |

| Immobilization Chemistry | Covalent coupling (e.g., amine coupling), affinity capture [21] | Covalent coupling (e.g., amine coupling), affinity capture [10] |

Table 1: Specification comparison between Biacore CM5 and XanTec CMD500M sensor chips.

Experimental Data from a Direct Performance Study

A recent comparative study conducted by Gnedenko et al. provides the critical experimental data required for an objective performance analysis [6]. This research was designed to test the practical interchangeability of the CM5 and CMD500M chips by using a standardized protein-protein interaction model.

Key Experimental Parameters

- Immobilized Ligand: Protein A was immobilized on both chip surfaces [6].

- Analyte: A series of concentrations of IgG antibody was used as the analyte flowing over the surfaces [6].

- Data Analysis: The resulting sensorgrams were fitted using a 1:1 Langmuir binding model to extract kinetic and affinity constants [6].

The study reported that the binding interactions on both chips were characterized by similar sensorgram shapes and high-quality model fits. The quantitative analysis revealed minimal differences in the calculated binding parameters, as summarized below:

| Binding Parameter | Biacore CM5 | XanTec CMD500M | Reported Difference |

|---|---|---|---|

| Association Rate Constant (kon) | Not specified | Not specified | 18% [6] |

| Dissociation Rate Constant (koff) | Not specified | Not specified | 10% [6] |

| Equilibrium Dissociation Constant (KD) | Not specified | Not specified | 9% [6] |

Table 2: Experimental results from the comparative SPR analysis of CM5 and CMD500M chips. Absolute values were not provided in the source, but the percentage differences between the chips were reported [6].

The small variances, particularly the 9% difference in KD (the key affinity parameter), led the study authors to conclude that the chips are effectively interchangeable for this type of interaction [6]. This data is a crucial benchmark for researchers considering a switch from the CM5 to the CMD500M.

Detailed Experimental Protocol for Chip Comparison

To independently verify performance or compare other chip pairs, the following detailed protocol, synthesizing methodologies from the cited research, can be implemented.

Reagent and Instrument Setup

This protocol requires specific reagents and equipment to ensure reproducibility.

Research Reagent Solutions

| Item | Function / Description |

|---|---|

| SPR Instrument | A Biacore X100 or comparable SPR system is required [6]. |

| Running Buffer | HBS-EP (10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% surfactant P20), pH 7.4, is standard for most studies [8]. |

| Ligand | A highly purified, stable protein. The model study used Protein A [6]. |

| Analyte | A binding partner for the ligand, available in a purified form and at a range of concentrations. The model study used IgG [6]. |

| Immobilization Reagents | For amine coupling: N-hydroxysuccinimide (NHS), N-ethyl-N'-(3-dimethylaminopropyl)carbodiimide (EDC), and an ethanolamine hydrochloride solution for blocking [8]. |

| Regeneration Solution | A solution that dissociates the analyte without damaging the immobilized ligand (e.g., 10 mM Glycine-HCl, pH 1.5-2.5) [10]. |

Table 3: Essential materials and reagents for performing a controlled chip comparison.

Step-by-Step Workflow

The experimental workflow for a direct chip comparison involves a series of structured steps, from surface preparation to data analysis, as illustrated below.

Figure 1: Experimental workflow for direct SPR chip comparison.

Data Analysis and Interpretation

The data processing and interpretation phase is critical for drawing meaningful conclusions from the experiment.

Figure 2: Data analysis workflow for SPR chip comparison.

The experimental data from the comparative study indicates that the Biacore CM5 and XanTec CMD500M sensor chips yield highly comparable results for a standard protein-protein interaction, supporting their functional interchangeability in this context [6]. The minimal differences in kinetic and affinity constants (≤18%) fall within an acceptable range for most bioanalytical applications.

A critical factor underpinning this performance is baseline stability. A stable baseline, characterized by low signal drift and minimal noise, is essential for obtaining high-quality, reproducible kinetic data. The dextran matrix in both chips contributes to this stability by providing a bioinert environment that minimizes non-specific binding [8] [21]. For researchers, the choice between these chips can therefore be confidently based on factors such as availability, cost, and specific experimental requirements beyond this model system.

This guide provides a validated framework for the direct comparison of SPR sensor chips. Researchers can adapt this protocol, including the specified reagents and analytical workflows, to objectively evaluate chip performance for their specific applications, ensuring the generation of reliable and robust data.

Establishing a Positive Control to Monitor Surface Validity Over Time

In the field of surface plasmon resonance (SPR) biosensing, the long-term stability and performance consistency of the sensor chip are critical for generating reliable, reproducible binding data. This is particularly true in drug discovery and development, where accurate kinetic characterization of biomolecular interactions can significantly impact candidate selection [6] [8]. However, researchers using popular SPR platforms like Biacore (“Cytiva”, USA) have faced practical challenges due to sanctions restrictions on the purchase of original consumables, primarily optical chips [6]. This has spurred interest in commercially available analogues, raising essential questions about their performance equivalence and long-term reliability.

Within this context, establishing a robust positive control system to monitor surface validity over time becomes paramount. This article objectively compares the baseline stability and analytical performance of the original Biacore CM5 sensor chip and its analogue, the CMD500M (“XanTec bioanalytics GmbH”, Germany), using a standardized Protein A/IgG interaction model. By framing this comparison within a broader thesis on SPR baseline stability, we provide researchers with a validated experimental framework for ongoing surface validity monitoring.

SPR Sensor Surfaces and the Need for Quality Control

SPR biosensors function by detecting real-time biomolecular interactions without labels. The core of this technology is a sensor chip, typically a glass substrate coated with a gold film and a chemical matrix that facilitates ligand immobilization [23]. The carboxymethylated dextran matrix, found on both CM5 and CMD500M chips, provides a hydrophilic environment that minimizes non-specific binding and offers a flexible scaffold for covalent coupling via amine chemistry [8] [10].

Surface validity can be compromised by several factors:

- Physical Degradation: Repeated injection-regeneration cycles can slowly degrade the matrix.

- Chemical Fouling: Aggregates or crude samples can cause non-specific adsorption.

- Ligand Inactivation: The immobilized ligand itself may lose activity over time or due to harsh regeneration conditions.

A well-designed positive control system detects these changes, ensuring that experimental data reflects true molecular interactions and not surface artifacts.

Comparative SPR Analysis: CM5 vs. CMD500M

Experimental Protocol for Positive Control Establishment

The following protocol, adapted from Gnedenko et al. (2024), details the steps for establishing a Protein A/IgG-based positive control to monitor surface validity [6].

1. Surface Preparation:

- Chip Conditioning: If using a new chip, prime the system with running buffer (e.g., HBS-EP: 10 mM HEPES, 150 mM NaCl, 3.4 mM EDTA, 0.005% surfactant P20, pH 7.4) until a stable baseline is achieved.

- Ligand Immobilization: Immobilize Protein A on both CM5 and CMD500M sensor chips using a standard amine coupling procedure.

- Activate the carboxyl groups on the dextran matrix with a 1:1 mixture of 0.4 M EDC (N-(3-dimethylaminopropyl)- N’-ethylcarbodiimide hydrochloride) and 0.1 M NHS (N-hydroxysuccinimide) for 7 minutes at a flow rate of 10 μL/min.

- Inject a 30-50 μg/mL solution of Protein A in 10 mM sodium acetate (pH 5.0) for 7 minutes to achieve a target immobilization level.

- Deactivate any remaining active esters with a 7-minute injection of 1 M ethanolamine-HCl (pH 8.5).

- Reference Surface: Create a reference flow cell by performing the same activation and deactivation steps without immobilizing Protein A.

2. Binding Assay and Data Collection:

- Analyte Preparation: Prepare a dilution series of human or rabbit IgG antibody in running buffer. A typical series might include 5-8 concentrations spanning a range below and above the expected KD (e.g., from low nM to hundreds of nM).

- Binding Cycle: For each concentration:

- Association Phase: Inject the IgG sample over the Protein A surface and the reference surface for 2-5 minutes to monitor binding.

- Dissociation Phase: Switch to a buffer flow for 10-30 minutes to monitor complex dissociation.

- Surface Regeneration: Inject a short pulse (15-60 seconds) of a regeneration solution (e.g., 10 mM glycine-HCl, pH 1.5-2.0) to completely remove bound antibody without damaging Protein A.

- Baseline Stability: Monitor the baseline resonance signal (in Resonance Units, RU) after each regeneration. A stable baseline that returns to its original level indicates good surface validity.

3. Data Analysis:

- Subtract the sensorgram from the reference flow cell to account for bulk refractive index changes and non-specific binding.

- Fit the corrected, concentration-dependent sensorgrams globally to a 1:1 Langmuir binding model using the instrument’s software (e.g., Biacore X100 Evaluation Software).

- Extract the key kinetic and affinity parameters: association rate constant (k

on), dissociation rate constant (koff), and equilibrium dissociation constant (KD= koff/kon).

Quantitative Comparison of CM5 and CMD500M Performance

A direct comparative study by Gnedenko et al. (2024) applied the above protocol to both chips, yielding the following quantitative results for the Protein A/IgG interaction [6]:

Table 1: Kinetic and Affinity Parameters for Protein A/IgG Interaction on CM5 and CMD500M Chips

| Parameter | Biacore CM5 Chip | XanTec CMD500M Chip | Percentage Difference |

|---|---|---|---|

| Association Rate Constant (k |

Reference Value | Comparable | 18% |

| Dissociation Rate Constant (k |

Reference Value | Comparable | 10% |

| Equilibrium Dissociation Constant (K |

Reference Value | Comparable | 9% |

The minimal differences in kinetic and affinity parameters, all within an acceptable 20% margin, confirm that the CMD500M chip is a functionally equivalent analogue to the original CM5 [6]. This establishes the Protein A/IgG pair as a reliable positive control system for monitoring either surface.

Workflow for Surface Validity Monitoring

The diagram below illustrates the logical workflow for establishing and using the Protein A/IgG positive control to monitor sensor chip validity over time.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful implementation of a surface validity control relies on key reagents and materials. The table below details essential solutions for this application.

Table 2: Key Research Reagent Solutions for SPR Surface Validity Control

| Reagent / Material | Function / Description | Application Note |

|---|---|---|

| Protein A | A stable bacterial protein that binds the Fc region of antibodies from many species. Serves as an ideal, reusable ligand. | Used for oriented immobilization of antibodies; robust to regeneration with low pH buffers [6] [10]. |

| IgG Antibody | The analyte that binds Protein A. Provides a consistent, well-characterized interaction for quality control. | Purified monoclonal or polyclonal IgG from human, rabbit, or mouse can be used. Consistent sourcing is key [6]. |

| CM5 or CMD500M Sensor Chip | The sensor surface with a carboxymethyl dextran matrix for ligand immobilization. | CMD500M is a sanctioned, functionally equivalent alternative to the original Biacore CM5 [6]. |

| EDC & NHS | Amine coupling chemistry reagents. Activate carboxyl groups on the chip matrix for covalent ligand attachment. | Standard for immobilizing proteins, peptides, and other biomolecules containing primary amines [8] [24]. |

| HBS-EP Buffer | Standard running buffer (HEPES, NaCl, EDTA, Surfactant P20). Provides a consistent chemical environment and reduces non-specific binding. | The surfactant P20 is critical for minimizing non-specific adsorption to the sensor surface [8]. |

| Glycine-HCl (pH 1.5-2.0) | Regeneration solution. Dissociates bound IgG from Protein A without permanently denaturing the ligand. | Allows for repeated use of the same positive control surface over dozens of cycles [6] [10]. |

The experimental data demonstrates that the CMD500M sensor chip is a functionally interchangeable alternative to the original CM5, with differences in key kinetic and affinity parameters of less than 20% for the model Protein A/IgG system [6]. This finding is significant for labs affected by supply chain disruptions, as it provides a validated path to maintaining SPR operations without compromising data quality.

The Protein A/IgG interaction pair serves as an excellent positive control for monitoring surface validity. Protein A is known for its robust, reversible binding to antibodies, allowing for numerous regeneration cycles. By periodically running a standardized IgG binding assay and comparing the derived kinetic constants (kon, koff, KD) to an established reference, researchers can objectively track surface performance. A significant drift in these parameters—for instance, a slowing of kon suggesting steric hindrance, or an increase in koff indicating ligand instability—signals a decline in surface validity. This proactive monitoring prevents the collection of erroneous data from compromised surfaces, saving time and valuable reagents.

In conclusion, within the broader thesis of SPR baseline stability, this guide provides a concrete, data-backed framework. Establishing a standardized positive control is not merely a best practice but a necessity for ensuring the integrity of kinetic data in critical applications like drug discovery and diagnostic development. The demonstrated interchangeability of CM5 and CMD500M chips, coupled with a robust monitoring protocol, empowers scientists to maintain the highest standards of analytical rigor in their SPR work.

Surface Plasmon Resonance (SPR) biosensing has become an indispensable tool for the real-time, label-free analysis of biomolecular interactions, providing critical insights into kinetics, affinity, and specificity [19]. The technique generates data in the form of a sensorgram—a plot of response versus time—from which key quantitative metrics are derived: the association rate constant (kon), the dissociation rate constant (koff), and the equilibrium dissociation constant (KD), which is the ratio koff/k_on [4]. The reliability of these parameters is fundamentally dependent on the stability of the SPR baseline and the performance of the sensor chip used.

For users of Biacore SPR systems, the CM5 sensor chip from Cytiva has long been a standard. However, recent sanctions restrictions on the purchase of original consumables have driven the need for commercially available alternatives [6]. The CMD500M sensor chip from XanTec bioanalytics GmbH has emerged as a direct analog to the CM5. This guide objectively compares the performance of these two chips, focusing on the critical metrics of kon, koff, and K_D, supported by experimental data and framed within the broader context of SPR baseline stability research.

Experimental Protocol for a Comparative Chip Study

A rigorous comparative study, as published in Biomedical Chemistry: Research and Methods, provides a validated protocol for evaluating the CM5 and CMD500M chips [6]. The following section details the methodology.

Materials and Immobilization

- Sensor Chips: The original Biacore CM5 chip ("Cytiva", USA) and its analog, the CMD500M chip ("XanTec bioanalytics GmbH", Germany), were used.

- Ligand and Analyte: Protein A was immobilized on both chips as the ligand. This protein is frequently used in research to orient antibodies on various surfaces. An IgG antibody was used as the analyte flowing in solution [6].

- Immobilization Chemistry: The immobilization of Protein A was performed using a standard amine-coupling chemistry. This typically involves activating the carboxymethylated dextran matrix of the sensor chip with a mixture of N-ethyl-N'-(3-dimethylaminopropyl)carbodiimide (EDC) and N-hydroxysuccinimide (NHS) to form reactive esters. Protein A is then injected, covalently bonding to the surface via primary amines. Finally, any remaining active esters are deactivated with ethanolamine [6] [5].

- Instrumentation: All experiments were conducted on a Biacore X100 SPR biosensor [6].

Data Acquisition and Analysis

- Binding Experiments: A series of solutions with different concentrations of the IgG antibody analyte were injected over the Protein A-functionalized chips. This allowed for the observation of the binding (association) and unbinding (dissociation) phases in real-time [6].

- Sensorgram Processing: The resulting sensorgrams were processed to subtract signals from a reference flow cell and blank buffer injections, ensuring that the final signal reflects only the specific interaction of interest [8].

- Kinetic Analysis: The processed sensorgrams for the various analyte concentrations were globally fitted to a 1:1 (Langmuir) binding model. This computational fitting directly extracts the kinetic rate constants, kon and koff. The equilibrium dissociation constant, KD, is then calculated as koff/k_on [6] [4].

The workflow is summarized in the diagram below:

Quantitative Performance Comparison: CM5 vs. CMD500M

The core of the comparison lies in the quantitative kinetic and affinity data derived from the sensorgrams. The following table summarizes the results of the comparative study, which are central to evaluating the performance and interchangeability of the two sensor chips.

Table 1: Comparative Kinetic and Affinity Parameters for CM5 and CMD500M Sensor Chips

| Parameter | Description | CM5 Chip Performance | CMD500M Chip Performance | Measured Difference |

|---|---|---|---|---|

| k_on (M⁻¹s⁻¹) | Association rate constant | Baseline Value | Comparable to CM5 | 18% [6] |

| k_off (s⁻¹) | Dissociation rate constant | Baseline Value | Comparable to CM5 | 10% [6] |

| K_D (M) | Equilibrium dissociation constant (koff / kon) | Baseline Value | Comparable to CM5 | 9% [6] |

Interpretation of Results

The data demonstrates a high degree of functional equivalence between the original CM5 and the analog CMD500M chip. The differences in all three key parameters are minimal, with the most significant variance being an 18% difference in kon. Crucially, the KD value, which defines binding affinity, differed by only 9%. This small discrepancy indicates that the switch from the original chip to its analog has a negligible impact on the measured affinity of the molecular interaction [6]. This level of agreement confirms that the CMD500M chip is a scientifically valid and reliable alternative to the original CM5 for this type of interaction study.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists key materials and reagents required to perform a comparative SPR study as described, along with their critical functions.

Table 2: Essential Research Reagent Solutions for SPR Chip Comparison

| Item | Function / Application |

|---|---|

| SPR Instrument (e.g., Biacore X100) | Platform for real-time, label-free detection of biomolecular interactions. |

| Sensor Chips (CM5 & CMD500M) | Gold surfaces with a carboxymethylated dextran matrix that serve as the foundation for ligand immobilization. |

| Ligand (e.g., Protein A) | The molecule immobilized on the sensor chip to capture the analyte. |

| Analyte (e.g., IgG Antibody) | The binding partner in solution, injected at varying concentrations for kinetic analysis. |

| EDC & NHS | Cross-linking reagents for activating the dextran matrix for covalent amine coupling. |

| Amine Coupling Buffers (e.g., Acetate) | Low-salt buffers at optimal pH to facilitate the electrostatic pre-concentration of the ligand prior to covalent coupling. |

| Running Buffer (e.g., HBS-EP) | The continuous-flow buffer that maintains a stable baseline and serves as the solvent for analyte dilutions. |

| Regeneration Solution (e.g., Glycine-HCl, pH 1.5-2.5) | A solution that breaks the ligand-analyte complex without damaging the ligand, allowing for chip re-use. |

Implications for Research and Development

The demonstrated interchangeability of the CM5 and CMD500M chips has significant practical implications. For researchers in drug development and basic science, it ensures experimental continuity and data reliability even when switching from original equipment manufacturer (OEM) parts to high-quality alternatives [6]. This is vital for long-term projects and for maintaining the integrity of data across publications.