Ensuring SPR Data Integrity: A Complete Guide to Baseline Stability Metrics and Quality Control

This article provides researchers, scientists, and drug development professionals with a comprehensive framework for understanding, monitoring, and optimizing baseline stability in Surface Plasmon Resonance (SPR) experiments.

Ensuring SPR Data Integrity: A Complete Guide to Baseline Stability Metrics and Quality Control

Abstract

This article provides researchers, scientists, and drug development professionals with a comprehensive framework for understanding, monitoring, and optimizing baseline stability in Surface Plasmon Resonance (SPR) experiments. Covering foundational principles to advanced validation techniques, it details how stable baselines are critical for generating reliable kinetic and affinity data in drug discovery applications. Practical methodologies for establishing quality metrics, systematic troubleshooting of common instability sources, and rigorous data validation protocols are presented to enhance data quality, reduce false results, and improve decision-making in biomedical research.

Why Baseline Stability is the Cornerstone of Reliable SPR Data

In surface plasmon resonance (SPR) analysis, the baseline signal is the foundational reference point obtained from a running buffer flowing over the sensor surface before and after an analyte binding event. Baseline stability refers to the degree to which this signal remains constant over time under stable environmental and instrumental conditions. A stable baseline is characterized by low drift (minimal gradual change in the signal over time) and low noise (minimal high-frequency signal fluctuations), and is paramount for obtaining reliable, high-quality data. It ensures that subsequent changes in the resonance signal can be attributed solely to the biomolecular interaction of interest, rather than to instrumental or buffer artifacts. Consequently, a thorough understanding and rigorous assessment of baseline stability is a critical prerequisite for any SPR experiment, forming the core of robust data quality metrics in drug development and basic research.

This guide provides an objective comparison of how different SPR sensor technologies and experimental protocols influence baseline stability, supported by experimental data and detailed methodologies.

Quantitative Comparison of SPR System Performance

The design of an SPR sensor directly influences its key performance parameters, including sensitivity, resolution, and ultimately, the stability of its baseline signal. The following table summarizes a comparative analysis of different SPR configurations based on key performance metrics relevant to baseline stability and data quality.

Table 1: Performance Comparison of Different SPR Sensor Designs

| SPR Sensor Design | Key Characteristics | Reported Sensitivity (RIU) | Factors Impacting Baseline Stability | Typical Applications |

|---|---|---|---|---|

| Conventional SPR (Prism) | Prism-coupled, thin metal film [1] | ~3×10⁻⁷ (Angular) [2] | Thermal drift, bulk refractive index changes, metal film adhesion [2] | Kinetic studies, biomolecular interactions [3] |

| Plasmon-Waveguide Resonance (PWR) | Dielectric layer (e.g., SiO₂) over metal film; enhances electric field penetration [2] | 0.5 to 8 fold less sensitive than conventional SPR in analytical parameters [2] | Increased penetration depth can reduce surface sensitivity; stability dependent on waveguide layer integrity [2] | Anisotropic materials (lipid bilayers), birefringence studies [2] |

| Photonic Crystal Fiber (PCF-SPR) | Microstructured fiber with internal metal coating; miniaturized and flexible [4] | High (varies with design) – e.g., ultra-sensitive designs for broad analyte detection [4] | Fabrication complexity, stability of light source, coating uniformity within fiber channels [4] | Portable biosensing, environmental monitoring, clinical diagnostics [4] |

| Spectral Imaging SPR (AOTF-λSPRi) | Imaging system with acousto-optic tunable filter for wavelength scanning [5] | High linearity (R² = 0.9931) [5] | Light source spectral stability; addressed via real-time AOTF amplitude calibration [5] | High-throughput biomolecular interaction monitoring, cell imaging [5] |

Experimental Protocols for Assessing Baseline Stability

To ensure the credibility of SPR data, specific experimental protocols must be followed to characterize and optimize baseline stability. The methodologies below are drawn from established research practices.

Protocol for Evaluating System-Level Drift

Objective: To quantify the inherent instrumental drift of the SPR system over a defined period under constant buffer flow. Methodology: [5]

- System Preparation: Clean the sensor chip and instrument flow cells according to manufacturer specifications. Prime the entire fluidic system with running buffer (e.g., HEPES-buffered saline or PBS).

- Data Acquisition: Initiate a continuous flow of running buffer at a standard rate (e.g., 30 μL/min). Begin recording the baseline signal (in Resonance Units - RU, or wavelength - nm) for an extended period, typically 1-2 hours, without introducing any analyte.

- Data Analysis: Plot the sensorgram (signal vs. time). The baseline drift is calculated as the total change in signal (ΔRU or Δnm) over the chosen time interval. High-performance systems should exhibit minimal drift (e.g., <5-10 RU over 1 hour).

Protocol for Light Source Stability Calibration in Spectral SPR

Objective: To correct for spectral distortions and intensity fluctuations in the light source, a major contributor to baseline noise and drift in spectral imaging SPR systems. [5] Methodology: [5]

- Setup: Utilize a spectral imaging SPR system equipped with an acousto-optic tunable filter (AOTF).

- Image Feedback Loop: Implement a software-controlled feedback mechanism. This system measures the light intensity from the detection image in real-time.

- Real-time Calibration: The measured intensity data is fed back to the AOTF, which adjusts its amplitude to calibrate and stabilize the output light source spectrum uniformly across the scan.

- Outcome: This method has been shown to enhance light source stability for long-time detection and increase the dynamic range by 20 nm, directly improving baseline reliability. [5]

Protocol for High-Linearity Resonance Value Calculation

Objective: To achieve rapid and accurate extraction of the resonance value (e.g., resonance wavelength) from spectral data, minimizing processing time and enhancing the linearity of the sensor response for real-time imaging. [5] Methodology: [5]

- Data Processing: After light source calibration, a threshold value is subtracted from the measured SPR curve.

- Centroid Calculation: The centroid (center of mass) of the area above this threshold is calculated. The horizontal coordinate of this centroid is used as the resonance value.

- Performance: This algorithm reduces the single-image calculation time to 600 ms and achieves a high linearity (R² = 0.9931), enabling real-time, stable baseline monitoring during fast scans. [5]

Signaling Pathways and Experimental Workflows

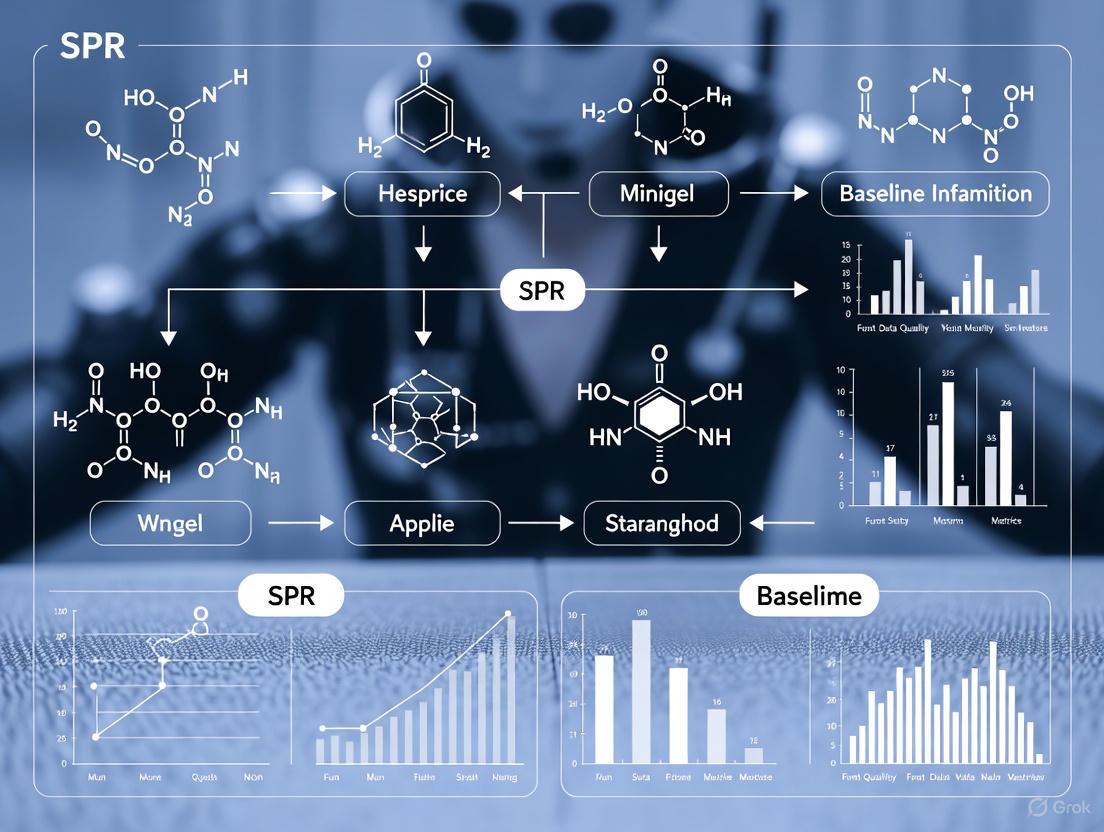

The following diagram illustrates the logical workflow for diagnosing and addressing common sources of baseline instability in an SPR experiment, integrating the protocols described above.

Diagram 1: A logical workflow for diagnosing and resolving baseline instability issues in SPR experiments.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key materials and reagents essential for conducting SPR experiments with high baseline stability, as cited in the referenced research.

Table 2: Essential Research Reagent Solutions for SPR Experiments

| Material/Reagent | Function in SPR Experiment | Specific Example from Literature |

|---|---|---|

| Gold & Silver Sensor Chips | The plasmon-active metal film that forms the core of the sensor surface. Gold is most common due to its chemical stability. [1] [2] | Used as the active layer in conventional SPR and as a base layer for PWR sensors. [2] |

| Chromium or Titanium Adhesion Layer | A thin layer (∼2 nm) deposited between the glass substrate and the gold film to promote adhesion. [2] | E-beam evaporation of 2 nm Cr was used in the fabrication of SPR and PWR chips. [2] |

| Silicon Dioxide (SiO₂) | A dielectric material used as a protective or waveguiding layer. It provides a hydrophilic surface suitable for biomolecule immobilization. [2] [4] | A 510 nm SiO₂ layer was used as the waveguide in PWR. A 3-6 nm layer was used to render chips hydrophilic. [2] |

| Phosphatidylcholine (PC) Lipids | Used to form lipid bilayer membranes on the sensor surface, mimicking cell membranes for studying membrane-protein interactions. [2] | PC lipids were used to create lipid vesicle solutions for deposition on the sensor surface. [2] |

| Ganglioside GM1 | A receptor embedded in a lipid bilayer, used as a model system for studying ligand-receptor interactions. [2] | GM1 was used as the receptor for Cholera toxin (CT) in a model binding study. [2] |

| Transition Metal Dichalcogenides (TMDs) / Graphene | 2D materials used as enhancement layers on the sensor surface to increase sensitivity and stability, often in PCF-SPR designs. [4] | Materials like MoS₂ and graphene are integrated with gold to optimize detection capabilities. [4] |

The Direct Impact of Baseline Drift on Kinetic Parameters (ka, kd, KD)

In surface plasmon resonance (SPR) biosensing, the real-time, label-free quantification of biomolecular interactions hinges on the precise measurement of subtle refractive index changes at the sensor surface. Baseline drift, the gradual shift in the baseline response signal before or after analyte injection, represents a fundamental challenge to data integrity. Within the context of SPR data quality metrics, uncontrolled drift directly compromises the accuracy of the extracted kinetic parameters—the association rate (ka), dissociation rate (kd), and equilibrium dissociation constant (KD). These parameters are critical in drug development, from the selection of therapeutic antibodies to the profiling of off-target binding interactions [6]. This guide objectively analyzes the impact of baseline drift, comparing data quality against established stability standards and providing methodologies for its quantification and correction.

Baseline drift is typically a sign of a non-optimally equilibrated sensor surface [7]. Its presence indicates that the system has not reached a stable physical or chemical state, leading to a continuous, time-dependent change in the background signal.

- Primary Causes: The most common sources include the rehydration of a newly docked sensor chip, wash-out of chemicals from the immobilization procedure, or the adjustment of the immobilized ligand to the flow buffer [7]. Drift can also occur after a change in running buffer if the system is not sufficiently primed and equilibrated.

- System Susceptibility: Some sensor surfaces are particularly susceptible to flow changes. Initiating flow after a standstill can cause a transient drift that levels out over 5–30 minutes [7]. Furthermore, the use of regeneration solutions can induce different drift rates on the active and reference surfaces due to differences in immobilized protein and immobilization levels.

The diagram below illustrates how these underlying causes propagate through the data analysis workflow to ultimately distort the final kinetic parameters.

Quantitative Impact of Drift on Kinetic Parameter Determination

The seemingly minor phenomenon of baseline drift has mathematically consequential and quantifiable effects on the key parameters measured in SPR kinetics. The following table summarizes the specific impacts on ka, kd, and KD.

Table 1: Direct Impacts of Baseline Drift on Key SPR Kinetic Parameters

| Kinetic Parameter | Impact of Baseline Drift | Underlying Mechanism | Quantitative Data Quality Metric |

|---|---|---|---|

| Association Rate Constant (ka) | Over- or Under-estimation [8] | Drift distorts the true slope of the association phase, which is critical for determining the observed rate constant (kobs) and, consequently, the ka. | Fit with and without a drift component; contribution should be low (e.g., < ± 0.05 RU/s) [8]. |

| Dissociation Rate Constant (kd) | Compromised Accuracy [8] | An unstable baseline makes it impossible to accurately model the exponential decay of the dissociation phase, leading to erroneous kd calculations. | Check if the dissociation is fitted correctly after initial fitting and if the curve follows the measured data [8]. |

| Equilibrium Dissociation Constant (KD) | Inaccurate Affinity Measurement (KD = kd/ka) | Since KD is derived from the ratio of kd and ka, any error in these kinetic rates propagates directly into the affinity constant, misrepresenting binding strength. | Chi² value and random residuals indicate a good fit; systematic patterns in residuals suggest model failure, often from unaccounted drift [8]. |

The reliability of these parameters is foundational for critical applications. For instance, in therapeutic development, the affinity of CAR-T cell therapies is optimally tuned to a specific range (KD ≈ 50–100 nM), and inaccurate KD measurements could lead to incorrect conclusions about a candidate's efficacy [6].

Experimental Protocols for Drift Assessment and Mitigation

Protocol for Diagnosing and Quantifying Baseline Drift

A systematic approach to diagnosing drift is essential for high-quality kinetics.

- System Equilibration: After docking a sensor chip or changing buffers, prime the system and flow running buffer until a stable baseline is achieved. This may require running buffer overnight for new surfaces [7].

- Buffer Injection Test: Inject running buffer over the active and reference surfaces and observe the baseline response. A stable system should have an overall noise level of < 1 Resonance Unit (RU) [7].

- Start-up Cycles: Integrate at least three start-up cycles into the experimental method. These cycles should mimic analyte injections but use running buffer instead, including regeneration steps if applicable. These cycles "prime" the surface and are not used in the final analysis [7].

- Residuals Analysis: After fitting the kinetic data to a model (e.g., 1:1 Langmuir), examine the residuals—the difference between the fitted curve and raw data. A good fit will have random residuals with an absolute value on the order of the instrument noise. Systematic patterns in the residuals indicate a poor fit, potentially caused by unaccounted-for drift or an incorrect model [8].

Standardized Mitigation Strategies in Kinetic Analysis

The following workflow outlines a standard procedure for minimizing the influence of baseline drift during experimental setup and data processing.

Supporting Methodological Details:

- Buffer Preparation: Prepare running buffer fresh daily, followed by 0.22 µM filtration and degassing to minimize air spikes and biological contamination. Avoid adding fresh buffer to old stocks [7].

- Blank Cycles: It is recommended to add blank (buffer) cycles evenly throughout the experiment, approximately one blank every five to six analyte cycles, ending with one [7].

- Double Referencing: This two-step procedure is critical for compensating for drift and bulk effects. First, subtract the response from a reference surface from the active surface. Second, subtract the average response from the blank injections [7].

- Drift as a Local Fitting Parameter: In data analysis software, drift can be included as a locally fitted parameter. Best practice is to first fit the curves without a drift component, then add it in the final fitting using initial values from the previous result. The contribution of drift should be low, typically < ± 0.05 RU/s [8].

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for Managing Baseline Stability

| Item | Function in Drift Mitigation | Application Notes |

|---|---|---|

| High-Purity Buffers | Provides a stable chemical environment; minimizes drift caused by buffer contamination or mismatch. | Prepare fresh daily, filter (0.22 µm), and degas. Use a consistent batch for running buffer and analyte dilution [7] [9]. |

| Reference Sensor Chips | Serves as a negative control surface for double referencing, isolating specific binding from bulk and drift effects. | Should closely match the active surface in matrix and immobilization chemistry (e.g., a blocked surface without active ligand) [8] [7]. |

| Surface Regeneration Solutions | Removes bound analyte without damaging the ligand, ensuring a stable baseline for subsequent injection cycles. | Must be optimized to be harsh enough for complete regeneration but mild enough to maintain ligand activity (e.g., Glycine pH 1.5-3.0, NaOH) [9]. |

| Bulk Effect Reduction Additives | Reduces non-specific binding and bulk refractive index shifts that can mask drift. | Use additives like BSA (1%) or non-ionic surfactants (e.g., Tween 20) in running buffer to stabilize proteins and shield hydrophobic interactions [9]. |

In the rigorous world of biomolecular interaction analysis, the stability of the SPR baseline is not a mere technicality but a fundamental determinant of data fidelity. As demonstrated, baseline drift directly and measurably distorts the kinetic parameters ka, kd, and KD, potentially leading to flawed conclusions in critical areas like drug candidate selection and off-target profiling [6]. Through the consistent application of standardized protocols—including rigorous system equilibration, strategic experimental design with blank cycles, and mandatory double referencing—researchers can effectively mitigate this issue. Adherence to these data quality metrics ensures that the reported kinetic constants truly reflect the biology under investigation, thereby bolstering the reliability of scientific findings and accelerating the development of novel therapeutics.

Correlation Between Baseline Noise and False Positive/Negative Binding Events

Surface Plasmon Resonance (SPR) technology has become a cornerstone technique in biomedical research and drug development for characterizing biomolecular interactions in real-time without labels. [3] [10] As SPR gains prominence in critical applications from diagnostic development to therapeutic antibody characterization, data quality assessment becomes increasingly crucial. Among various data quality metrics, baseline stability serves as a fundamental indicator of system performance and experimental integrity. Excessive baseline noise directly correlates with increased incidence of false positive and false negative binding events, potentially compromising research validity and therapeutic development pipelines. This review systematically examines the relationship between baseline noise and erroneous binding interpretations within SPR systems, comparing performance across instrumental approaches and providing methodological frameworks for noise mitigation.

Physical Origins of Baseline Instability

Baseline noise in SPR systems originates from multiple physical and experimental factors that collectively degrade signal quality. The evanescent field responsible for SPR signal generation typically extends 100-200 nm from the sensor surface, making it exquisitely sensitive to minute refractive index changes within this region. [10] While this confined sensitivity enables detection of molecular binding events, it also renders the system vulnerable to various noise sources. Thermal fluctuations within the fluidic system create microscopic refractive index variations that manifest as baseline drift and high-frequency noise. [11] Additionally, microbubble formation in flow channels or imperfections in gold film morphology introduce sudden signal artifacts that can mimic binding events. [10] The fundamental signal-to-noise ratio in SPR is constrained by the propagation length of surface plasmon polaritons along the metal-dielectric interface, which typically ranges from 10-100 μm depending on the metal film quality and excitation wavelength. [12]

Instrument-Specific Noise Characteristics

Different SPR configurations exhibit distinct noise profiles that influence their susceptibility to false interpretations. Traditional prism-coupled SPR systems, while offering excellent bulk refractive index sensitivity, often demonstrate increased vulnerability to temperature fluctuations due to their larger interaction volumes. [12] In contrast, localized SPR (LSPR) platforms utilizing nanoparticle transducers benefit from significantly reduced thermal drift due to their smaller footprint, but may exhibit higher baseline noise from nanoparticle heterogeneity. [1] Emerging SPR microscopy (SPRM) systems achieve remarkable spatial resolution (~300 nm) but face unique noise challenges from parabolic tail artifacts in the propagation direction of surface plasmon waves. [12] The recent development of surface plasmonic scattering microscopy (SPSM) addresses several limitations of conventional SPRM by directly collecting scattered surface plasmon waves, thereby eliminating interference artifacts and achieving diffraction-limited spatial resolution without post-processing requirements. [12]

Impact of Baseline Noise on Binding Event Interpretation

Quantitative Relationship Between Noise and False Results

The correlation between baseline noise amplitude and erroneous binding event classification follows predictable statistical patterns that can be quantified through signal processing approaches. When baseline noise (expressed as resonance unit standard deviation) exceeds 0.5 RU, the probability of false positive classification for weak affinity interactions (KD > 10 μM) increases exponentially. [11] For typical small molecule screening applications where binding responses may be ≤ 5 RU, maintaining baseline noise below 0.3 RU is critical for maintaining >95% confidence in binding event discrimination. [11] The table below summarizes noise tolerance thresholds for different interaction types:

Table 1: Baseline Noise Tolerance Guidelines for Different Binding Interaction Types

| Interaction Type | Typical Response Range (RU) | Maximum Recommended Noise (RU) | Primary False Risk |

|---|---|---|---|

| High-affinity protein-protein | 50-200 | 1.0 | False negative due to mass transport limitation |

| Low-affinity protein-small molecule | 5-20 | 0.3 | False positive from noise spikes |

| Antibody-antigen (monoclonal) | 100-300 | 1.5 | False negative from incomplete regeneration |

| Nucleic acid hybridization | 30-100 | 0.5 | False positive from non-specific binding |

| Cell membrane receptor | 10-50 | 0.8 | Both false positive and negative |

Mechanistic Pathways to False Results

Baseline noise contributes to erroneous binding interpretations through several well-characterized mechanistic pathways that operate independently or synergistically:

High-frequency noise spikes represent the most direct pathway to false positives, as transient signal excursions exceeding typical binding thresholds may be misinterpreted as legitimate binding events. [13] [11] Conversely, low-frequency baseline drift more commonly produces false negatives by obscuring legitimate binding events through gradual signal baseline elevation that causes authentic interactions to fall below response threshold criteria. [11] Perhaps most insidiously, moderate-frequency noise in the 0.1-1 Hz range directly interferes with accurate kinetic parameter extraction, leading to both qualitative binding misinterpretations and quantitatively erroneous association/dissociation constant calculations. [11] [14]

Comparative Performance of SPR Platforms

Baseline Stability Across Instrument Classes

Different SPR configurations exhibit characteristic baseline performance profiles that directly influence their susceptibility to false binding interpretations. The following table compares noise characteristics across major SPR platform types:

Table 2: Baseline Performance Comparison Across SPR Platform Types

| SPR Platform | Typical Baseline Noise (RU) | Primary Noise Sources | Optimal Application Context |

|---|---|---|---|

| Conventional prism-coupled SPR | 0.1-0.5 | Thermal drift, buffer mismatches | High-affinity interaction analysis |

| Fiber-optic SPR | 0.5-2.0 | Light source fluctuation, bending losses | Portable field deployment |

| LSPR (nanoparticle-based) | 1.0-5.0 | Nanoparticle heterogeneity | Small molecule screening |

| SPR imaging (SPRi) | 0.5-3.0 | Image sensor noise, non-uniform illumination | Multiplexed biomarker detection |

| SPR microscopy (SPRM) | 0.3-1.0 | Scattering artifacts, parabolic tails | Single particle/cell analysis |

| Surface plasmonic scattering microscopy (SPSM) | 0.1-0.8 | Laser intensity noise | High-resolution molecular imaging |

Traditional Kretschmann-configuration SPR systems generally provide the lowest baseline noise (0.1-0.5 RU) when properly optimized, making them particularly suitable for characterizing weak affinity interactions and small molecule binding. [3] [10] In contrast, localized SPR (LSPR) platforms typically exhibit higher baseline noise (1.0-5.0 RU) due to ensemble averaging across structurally heterogeneous nanoparticle populations, restricting their utility to higher-response applications. [1] Emerging high-resolution techniques like SPR microscopy (SPRM) achieve impressive spatial resolution while maintaining moderate baseline noise (0.3-1.0 RU), though they require specialized processing to mitigate parabolic tail artifacts that can generate false binding interpretations in densely-distributed samples. [12]

Methodological Approaches for Noise Reduction

Multiple experimental strategies exist for mitigating baseline noise across SPR platforms, each targeting specific noise mechanisms:

Buffer matching through meticulous formulation and degassing remains the most fundamental approach, as refractive index differences as small as 10⁻⁵ RIU can generate response shifts equivalent to substantial binding signals. [11] Temperature stabilization within ±0.1°C is equally critical, as temperature-dependent refractive index changes produce approximately 10⁻⁴ RIU/°C, potentially obscuring legitimate binding events or generating false positives. [11] For applications requiring maximum sensitivity, surface chemistry optimization through appropriate blocking agents (BSA, casein, or surfactant additives) and controlled immobilization densities directly addresses non-specific binding contributions to baseline instability. [11] [10]

Experimental Protocols for Baseline Noise Assessment

Standardized Noise Measurement Methodology

Consistent quantification of baseline noise requires standardized experimental protocols and analysis parameters. The following procedure establishes a framework for reproducible noise assessment:

System Preparation: Equilibrate the SPR instrument with running buffer for at least 30 minutes at the standard operational flow rate (typically 25-30 μL/min). Ensure thorough degassing of all buffers and temperature stabilization to ±0.1°C of setpoint.

Surface Conditioning: Prime the system with three consecutive 1-minute injections of running buffer followed by stabilization periods to establish a reproducible starting surface state.

Data Acquisition: Collect baseline data for a minimum of 300 seconds (5 minutes) at the standard measurement frequency (typically 1-10 Hz) without any analyte injections or flow changes.

Noise Calculation: Calculate baseline noise as the standard deviation of response units (RU) over the final 180 seconds of stable baseline, excluding the initial stabilization period.

This protocol should be performed following system maintenance, sensor chip installation, or when troubleshooting suspect data quality. [11] [14]

Non-Specific Binding Evaluation Protocol

Non-specific binding (NSB) represents a significant contributor to baseline instability and false binding interpretations. The following experimental approach quantitatively evaluates NSB:

Surface Preparation: Immobilize the standard ligand following established protocols for the application.

Negative Control Selection: Identify structurally similar but non-interacting analytes as negative controls (e.g., scrambled sequences for nucleic acids, irrelevant antibodies for immunoassays).

NSB Testing: Inject negative control analytes at concentrations 10-fold above the expected KD of target interactions.

Quantification: Measure response relative to reference surface. NSB exceeding 5% of specific signal warrants mitigation strategies. [11]

Effective NSB reduction approaches include adjustment of buffer pH relative to analyte isoelectric point, addition of non-interacting proteins (BSA ≤1%), incorporation of mild surfactants (Tween 20), or increased ionic strength to disrupt charge-based interactions. [11]

Essential Research Reagent Solutions

Table 3: Key Research Reagents for SPR Baseline Optimization

| Reagent Category | Specific Examples | Functional Role | Optimization Considerations |

|---|---|---|---|

| Surface Chemistry | CM5, C1, NTA sensor chips | Molecular immobilization | Match surface chemistry to ligand properties |

| Blocking Agents | BSA, casein, surfactant solutions | Non-specific binding reduction | Concentration optimization required |

| Running Buffers | HBS-EP, PBS, Tris-based | System equilibration | Thorough degassing essential |

| Regeneration Solutions | Glycine (pH 1.5-3.0), NaOH, SDS | Surface restoration | Ligand stability validation required |

| Immobilization Reagents | EDC/NHS, amine coupling kits | Covalent attachment | Density optimization critical |

| Reference Analytes | Non-interacting proteins | Specificity validation | Structural similarity to test compounds |

Baseline noise in SPR systems exhibits a direct and quantifiable relationship with false positive and false negative binding events, with specific mechanistic pathways operating across different noise frequency domains. Through systematic characterization of noise sources, implementation of appropriate mitigation strategies, and selection of optimal SPR platforms for specific applications, researchers can significantly enhance data reliability. The experimental frameworks and comparative performance data presented herein provide practical guidance for maintaining baseline stability across diverse SPR applications. As SPR technology continues evolving toward higher sensitivity and miniaturization, vigilant attention to baseline quality control remains essential for generating biologically meaningful interaction data and avoiding erroneous conclusions in therapeutic development pipelines.

Instrument-Specific Baseline Performance Standards and Acceptable Noise Levels

In Surface Plasmon Resonance (SPR) biosensing, the quality of the baseline—the signal recorded before an analyte is introduced—is a fundamental determinant of data reliability and experimental success. A stable, low-noise baseline is the essential foundation upon which accurate quantification of binding kinetics (association rate, k_on, dissociation rate, k_off) and affinity (K_D) rests. Within the broader context of establishing rigorous SPR data quality metrics, this guide objectively compares the baseline performance and noise levels of several commercially available SPR instruments. The baseline constitutes the initial flat line on a sensorgram, representing the system's equilibrium state prior to analyte injection. Instability or excessive noise at this stage can obscure genuine binding signals, compromise the accuracy of fitted kinetic parameters, and lead to erroneous conclusions in critical research areas like drug candidate screening and antibody characterization. This guide provides researchers, scientists, and drug development professionals with a comparative analysis of instrument-specific baseline performance, supported by experimental data and detailed methodologies.

Core Principles: Defining a Quality Baseline

A quality SPR baseline is characterized by two key attributes: stability and low noise. The baseline must be stable, meaning it exhibits minimal drift over time. Furthermore, the signal noise must be sufficiently low to distinguish small but significant binding responses from random background fluctuations.

- Baseline Stability: For an inert surface in water at room temperature, a stable baseline should typically exhibit a drift of less than 1 Hz/hour for the frequency signal. This level of stability ensures that slow, systematic shifts in the signal do not interfere with the measurement of binding events [15].

- Acceptable Noise Levels: The standard deviation of the noise should be less than 0.2 Hz for the frequency signal. Low noise is critical for detecting weak interactions or for working with low molecular weight analytes that produce small response shifts [15].

A baseline that is too short or shows significant drift, as illustrated in the figures below, prevents researchers from trusting that the subsequent binding data is uncontaminated by underlying system artifacts [15].

Visual Guide to Baseline Quality

The following diagrams illustrate the key characteristics of a poor baseline, which must be avoided to ensure data integrity.

Diagram 1: Baseline quality characteristics.

The Sensorgram in Context: The Baseline's Role in the Binding Cycle

The baseline is the first of four critical phases in a complete SPR binding cycle. Understanding its relationship to the subsequent phases—association, dissociation, and regeneration—is key to holistic data interpretation.

Diagram 2: The four-phase SPR binding cycle.

Comparative Performance Data of SPR Instruments

The following tables summarize the key specifications and performance characteristics of various SPR instruments, with a focus on throughput, detection capabilities, and relevant baseline considerations.

Instrument Specifications and Throughput

Table 1: Comparison of commercial SPR instrument specifications and throughput.

| Instrument / Manufacturer | Detection Channels / Sensor Spots | Key Technology / Features | Throughput and Sample Handling |

|---|---|---|---|

| SPR #64 [16] | Up to 64 spots simultaneously | Rotatable 8-channel microfluidics; SPR+ detection | Injects 8 samples simultaneously; >30,000 interactions/24h |

| Sierra SPR-32/24 Pro [16] | 32 or 24 spots (8 flow cells) | Hydrodynamic Isolation (HI); SPR+ detection | Injects 8 samples simultaneously; ~8,800-10,000+ interactions/24h |

| inQuiQ (Delta Life Science) [16] | 16-plex measurements | Nanophotonic Enhanced Sensing (NES); Silicon chip with polycarboxylate hydrogel | Sample volumes from 25 µL to 2 mL |

| OpenSPR (Nicoya) [17] | Not specified | Benchtop form factor | Low sample consumption |

| Pioneer (Sartorius) [16] | Not specified | OneStep Injection (creates a concentration gradient in a single injection) | Reduces need for multiple sample dilutions; saves time and sample |

| P4SPR [16] | 4 channels | Portable, open architecture | Suitable for complex media (e.g., serum) |

Performance Comparison and Baseline Considerations

Table 2: Instrument performance data and baseline-related characteristics.

| Instrument / Manufacturer | Reported Performance Data | Implications for Baseline Stability & Data Quality |

|---|---|---|

| OpenSPR [17] | Protein-protein interaction: K_D = 1.53 nM; k_off = 1.25e-3 1/s |

Produces high-quality data with excellent curve fits; K_D values are comparable to, though distinct from, other instruments, highlighting the need for consistent baselines. |

| Standard SPR Instrument (for comparison) [17] | Protein-protein interaction: K_D = 0.686 nM; k_off = 5.61e-4 1/s |

Serves as a benchmark. The difference in k_off and K_D vs. OpenSPR underscores that cross-instrument comparisons require careful control of baseline conditions. |

| Pioneer FE System [16] | Optimized for fragment-based drug discovery (FBDD) | Higher sensitivity and NeXtStep injection technology improve the detection of weak binding events, which relies intrinsically on a very stable, low-noise baseline. |

| iMSPR-mini (iClubio) [16] | Entry-level, 2-channel model | Suitable for educational practice and basic research where baseline requirements may be less stringent than in regulated drug development. |

Experimental Protocols for Establishing Baseline Performance

Standardized Protocol for Assessing Baseline Stability

This protocol provides a method to quantitatively evaluate an instrument's baseline performance, which is a critical first step before any binding kinetics experiment.

- Sensor Chip & Surface Preparation: Use a clean, inert sensor surface. A bare gold chip or one coated with a non-binding, hydrophilic polymer (e.g., carboxymethyl dextran without immobilized ligand) is suitable. Ensure the chip and all fluidic components are rigorously cleaned according to the manufacturer's instructions to prevent contamination [15] [18].

- Running Buffer: Use a high-purity, filtered (0.22 µm) and degassed buffer. Phosphate-buffered saline (PBS) is a common choice. Consistency between the running buffer and the sample buffer is critical to prevent bulk refractive index shifts.

- Data Acquisition: With the buffer flowing at a standard rate (e.g., 30 µL/min), record the baseline signal for a minimum of 5 to 10 minutes to adequately assess stability. The baseline must not be too short [15].

- Data Analysis: Calculate the standard deviation (S.D.) of the signal over a stable portion of the baseline to quantify noise. It should ideally be < 0.2 Hz [15]. Plot the signal over time and perform a linear regression. The slope of this line, expressed in Hz/hour, quantifies the drift, which should be < 1 Hz/hour for a high-quality baseline [15].

Protocol for a Comparative Binding Kinetics Study

The following methodology was used to generate the comparative protein-protein interaction data presented in [17] and summarized in Table 2.

- Ligand Immobilization: The ligand (one interacting protein) is immobilized onto a sensor chip surface using a standard coupling chemistry, such as amine coupling. The immobilization level should be controlled to avoid mass transport limitations.

- Analyte Dilution Series: The analyte (the binding partner) is prepared in a series of concentrations (e.g., 6.25, 12.5, 25, 50 nM) using the running buffer. Serial dilution is performed accurately to minimize pipetting error.

- Binding Cycle Execution:

- Baseline Establishment: The running buffer is flowed over the ligand surface until a stable baseline is achieved (as defined in Section 4.1).

- Association Phase: The analyte sample is injected over the surface for a fixed period (typically 1-3 minutes), during which the binding response increases.

- Dissociation Phase: The flow is switched back to running buffer, and the dissociation of the complex is monitored for a sufficient time to reliably determine the off-rate.

- Regeneration: A regeneration solution (e.g., low pH glycine) is injected for a short pulse to remove all bound analyte, returning the signal to the original baseline. This confirms a successful cycle and prepares the surface for the next analyte concentration.

- Data Analysis: The resulting sensorgrams for all concentrations are globally fitted to a 1:1 Langmuir binding model using the instrument's software. This fitting procedure calculates the kinetic rate constants (

k_on,k_off) and the equilibrium dissociation constant (K_D=k_off/k_on).

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key research reagent solutions for SPR experiments focused on baseline quality.

| Item | Function & Importance | Considerations for Baseline Stability |

|---|---|---|

| Sensor Chips [16] | The solid support onto which the ligand is immobilized. The surface chemistry is foundational. | Clean, pristine chips are essential. Hydrophilic, neutrally charged surfaces (e.g., with hydrogel coatings) can minimize non-specific binding, a common cause of baseline drift [18]. |

| Running Buffer [18] | The solution that continuously flows through the instrument, establishing the chemical environment. | Must be high-purity, filtered, and degassed. Contaminants or bubbles cause severe baseline spikes and drift. Buffer composition must match sample buffer to avoid bulk shifts. |

| Regeneration Solution [18] | A solution that removes bound analyte from the immobilized ligand without damaging it. | Essential for re-using sensor surfaces. An ineffective regeneration leads to a progressively rising baseline over multiple cycles. Common reagents are glycine-HCl (low pH) or NaOH. |

| Analysis Software | The platform used to process raw data, fit binding models, and extract kinetic parameters. | The software's algorithm for baseline subtraction directly impacts the calculated kinetic constants. Consistent software settings are vital for cross-instrument comparisons [17]. |

The establishment of instrument-specific baseline performance standards is not merely a procedural formality but a critical component of robust SPR research. As the data shows, even instruments producing high-quality kinetic data can yield variations in fitted parameters like k_off and K_D [17]. Adherence to the following best practices is essential for generating reliable, reproducible data:

- Prioritize Baseline Stability: Never begin an experiment on a drifting or noisy baseline. If drift exceeds ~1 Hz/hour, extend the rinsing time or investigate and eliminate potential causes like contaminated buffers, a dirty fluidic path, or an improperly prepared sensor chip [15].

- Establish a Minimum Baseline Duration: Ensure a stable baseline of at least 5 minutes before analyte injection to confirm system equilibrium [15].

- Implement Rigorous Controls: Always include a reference flow cell or sensor spot (with no ligand or an irrelevant ligand) to identify and subtract non-specific binding and refractive index artifacts, which is crucial for a clean baseline and accurate interpretation.

- Validate Instrument Performance: Periodically run a standardized protein-protein interaction test (as described in Section 4.2) to verify that the instrument's output, including baseline stability, noise, and resulting kinetic constants, remains within an acceptable expected range over time.

Proven Methodologies for Achieving and Measuring Stable Baselines

Surface Plasmon Resonance (SPR) is a label-free biosensing technique that provides real-time monitoring of biomolecular interactions, making it a cornerstone technology in drug discovery and basic research [6] [19]. The quality of SPR data, however, is profoundly dependent on two fundamental aspects of experimental design: buffer matching and system equilibration. In the context of research on SPR data quality metrics for baseline stability, these factors are not merely preliminary steps but are critical determinants of the signal-to-noise ratio, measurement accuracy, and overall reliability of the derived kinetic and affinity constants [9] [20]. This guide objectively compares the performance implications of various buffer strategies and equilibration protocols, providing a framework for optimizing data quality.

The Critical Role of Buffer Matching

The Problem of Bulk Refractive Index Shift

Buffer matching primarily addresses the issue of bulk refractive index (RI) shift, also known as the solvent effect. This artifact occurs when the refractive index of the analyte solution differs from that of the running buffer [9]. During an SPR injection, this difference produces a large, rapid response change at the start and end of the injection, creating a characteristic 'square' shape in the sensorgram [9]. While this bulk shift does not alter the inherent kinetics of the binding partners, it complicates the differentiation of small binding-induced responses and can obscure interactions with rapid kinetics [9].

Strategies for Buffer Matching and Artifact Mitigation

Although reference subtraction can partially compensate for bulk shifts, the correction may not always be adequate [9]. Consequently, the most robust strategy is to match the components of the analyte buffer to the running buffer as closely as possible. This often requires careful buffer exchange of the analyte sample into the running buffer using techniques like dialysis or desalting columns.

For cases where certain additives cannot be omitted because they stabilize or solubilize the analyte or ligand molecules, specific mitigation strategies can be employed. The table below summarizes recommendations for common buffer components known to cause bulk shifts.

Table 1: Strategies to Mitigate Bulk Shift from Common Buffer Components

| Buffer Component | Potential Impact | Recommended Mitigation Strategy |

|---|---|---|

| Glycerol | High RI can cause significant bulk shift [9] | Use at the lowest possible concentration (e.g., <2%) or avoid entirely [9] |

| DMSO | High RI can cause significant bulk shift [21] | Use low, consistent concentrations; ensure matching between ligand and reference surfaces; consider system calibration [21] |

| High Salt Concentrations | Alters RI and can cause non-specific binding [9] [21] | Match salt concentrations exactly between running buffer and analyte samples [9] |

| Detergents (e.g., Tween-20) | Essential for solubility but can alter RI [21] | Include at low, consistent concentrations (e.g., 0.01-0.1%) in both running buffer and analyte samples [9] [21] |

System Equilibration for Baseline Stability

Defining a Stable Baseline

A stable baseline is the foundation of reliable SPR analysis. It represents the system's signal when no binding is occurring, providing a reference point from which all binding responses are measured. In practice, for an inert surface in water at room temperature, a frequency drift of less than 1 Hz per hour is a good benchmark for a stable baseline [20]. The required level of stability, however, is experiment-dependent; detecting small frequency shifts demands a more stable baseline than experiments with large expected signal changes [20].

Factors Affecting Equilibration and Baseline Stability

Achieving a stable baseline requires the elimination of factors that cause uncontrolled changes in the measured signal [20]. The following physical and experimental factors must be managed during system equilibration.

Table 2: Factors Impacting System Equilibration and Baseline Stability

| Factor | Impact on Baseline | Solution for Stabilization |

|---|---|---|

| Temperature Fluctuations | SPR response is highly sensitive to temperature changes, causing signal drift [20] | Use an instrument with robust temperature control; allow sufficient time for full system thermal equilibration before data collection [20] |

| Air Bubbles | Cause sharp, unpredictable spikes and drifts in both frequency and dissipation signals [20] | Properly degas all buffers prior to use; ensure the fluidic system is free of bubbles [20] |

| Poor Electrical Contact | Can increase measured dissipation factor and contribute to noise and drift [20] | Ensure secure and reliable electrical connections in the instrument [20] |

| Sensor Mounting Stresses | Improper mounting introduces stress that influences all resonant frequencies [20] | Follow manufacturer protocols for sensor mounting to avoid introducing physical stress [20] |

| Solvent Leaks / O-Ring Swelling | Can lead to liquid entering sensitive parts of the measurement chamber, causing large signal changes [20] | Check for leaks; ensure proper sensor mounting; monitor O-ring integrity, especially when switching solvents [20] |

The relationship between these factors and the resulting data quality can be visualized as a causal pathway.

Figure 1: Pathway to Data Quality. This diagram illustrates how uncontrolled experimental factors lead to system instabilities, which ultimately compromise data quality in SPR experiments.

Experimental Protocols

Protocol for Buffer Matching and Preparation

This protocol ensures minimal bulk shift and non-specific binding.

- Running Buffer Selection: Begin with a standard, biologically compatible buffer such as HBS-PE (10 mM HEPES pH 7.4, 150 mM NaCl, 3.4 mM EDTA, 0.01% Surfactant P20), TBS-P, or PBS-P [21].

- Buffer Supplementation: To minimize non-specific binding (NSB) and analyte adsorption, add blocking agents like 0.1% BSA or adjust detergent/salt concentrations (e.g., up to 0.1% Tween-20 or 250 mM NaCl) [9] [21]. Note: If using BSA, add it to the running buffer during analyte injections only, not during ligand immobilization, to prevent coating of the sensor chip [9].

- Buffer Preparation:

- Analyte Sample Preparation: Prepare the analyte via buffer exchange (e.g., using dialysis or desalting columns) into the final running buffer from step 3. If certain additives (e.g., DMSO, glycerol) are absolutely necessary, their concentration must be matched exactly in a dummy sample or in the running buffer itself [9] [21].

Protocol for System Equilibration and Baseline Stabilization

This protocol should be performed prior to any ligand immobilization or analyte injection.

- Initial System Priming: Prime the entire fluidic path of the SPR instrument with the filtered and degassed running buffer.

- Thermal Equilibration: Allow the instrument to circulate running buffer until the signal baseline stabilizes. This may take 30-60 minutes or more to ensure the sensor chip, fluidics, and running buffer have all reached a stable, set temperature [20].

- Baseline Stability Check: Monitor the baseline signal on a bare or reference sensor surface. A stable baseline should show minimal drift (e.g., <1 Hz/hour for highly sensitive measurements) [20].

- Troubleshooting Drift: If significant drift persists, investigate common causes:

The Scientist's Toolkit: Essential Research Reagents

Successful SPR experiments require careful selection of reagents to prepare the surface, manage the interaction, and maintain stability.

Table 3: Key Reagent Solutions for SPR Experiments

| Reagent / Material | Function in SPR Experiment | Example Usage & Rationale |

|---|---|---|

| HEPES-buffered Saline (HBS-EP) | A common running buffer; provides a stable pH and ionic strength environment for biomolecular interactions [21]. | Used as the standard running buffer for many protein-protein interaction studies; contains a surfactant to minimize NSB [21]. |

| Bovine Serum Albumin (BSA) | A blocking agent used to minimize non-specific binding and prevent analyte adsorption to vials and tubing [9] [21]. | Added to running buffer at 0.1-1% concentration during analyte injections to shield molecules from non-specific interactions [9]. |

| Non-ionic Surfactant (e.g., Tween-20, P20) | Mild detergent that disrupts hydrophobic interactions between the analyte and sensor surface, reducing NSB [9] [21]. | Used at 0.01-0.1% in running buffer to suppress NSB caused by hydrophobic effects [9] [21]. |

| L1 Sensor Chip | A carboxymethyldextran sensor chip with hydrophobic patches that capture intact lipid vesicles or liposomes [19]. | Essential for studying lipid-protein interactions or membrane-associated targets; captures intact lipid bilayers to mimic cellular membranes [19]. |

| Regeneration Solutions | Solutions used to completely dissociate bound analyte from the immobilized ligand between analysis cycles without damaging ligand activity [9]. | Common reagents: low pH (10 mM Glycine-HCl, pH 2.0-3.0), high salt, or chelating agents. Selected based on ligand-analyte complex stability [9]. |

| CHAPS / β-Octylglucoside | Detergents used to strip lipid surfaces from L1 sensor chips for re-use [19]. | Injected to clean and regenerate the L1 chip surface after lipid-protein interaction experiments [19]. |

Buffer matching and system equilibration are not mere preparatory steps but are foundational to generating publication-quality SPR data. As demonstrated, mismatched buffers directly introduce bulk refractive index artifacts that can obscure genuine binding events, particularly for interactions with fast kinetics or small response signals [9]. Similarly, an inadequately equilibrated system manifests as baseline drift, increasing noise and compromising the accuracy of fitted kinetic parameters (ka, kd) and affinity constants (KD) [20]. A rigorous approach to these initial experimental stages, as outlined in the provided protocols, is the most effective strategy to ensure data reliability, enhance measurement sensitivity, and ultimately, yield kinetically and thermodynamically meaningful results for drug development and basic research.

Surface Plasmon Resonance (SPR) is a powerful, label-free technology for the real-time analysis of biomolecular interactions. The data acquired from an SPR instrument, displayed as a sensorgram, is a graph plotting the SPR response (in Response Units, RU) against time (in seconds). [22] The quality of the kinetic or affinity constants derived from this data is fundamentally dependent on the proper preprocessing of the raw sensorgram. Preprocessing aligns the data and removes systematic artifacts, ensuring that the final analyzed signal reflects only the specific binding interaction of interest. This guide details the critical steps of baseline alignment and reference subtraction, framing them within the essential context of baseline stability research, a key metric for assessing data quality and instrument performance. [23]

Core Preprocessing Steps

Baseline Alignment

Purpose: Baseline alignment corrects for slight differences in the absolute response level (y-axis) among a set of sensorgrams before the injection of the analyte begins. This ensures that all sensorgrams within a dose-response set share a common starting point of zero RU, which is crucial for the accurate comparison and fitting of binding curves. [22] [24]

Step-by-Step Protocol:

- Select Baseline Region: Identify a stable, flat region of the sensorgram immediately before the start of the analyte injection. Avoid areas with spikes or significant drift. [24]

- Apply Alignment: Using the SPR evaluation software (e.g., ProteOn Manager, Scrubber, or Genedata Screener), select the function for baseline alignment or "Zero in Y." [22] [24]

- Define Scope: The software will typically allow you to apply the alignment to the entire sensorgram or to a selected region. For baseline alignment, the selected pre-injection region is used. [22]

- Execute: The software calculates the average response in the selected region and subtracts this value from the entire sensorgram, setting the baseline to zero.

Reference Subtraction

Purpose: Reference subtraction is the most important step for isolating a specific binding signal. It removes responses caused by the bulk effect (refractive index change from buffer mismatches) and nonspecific binding (NSB) to the sensor surface. [22] This process, often called double referencing, involves subtracting responses from control surfaces and injections. [24]

Step-by-Step Protocol:

Blank Surface Referencing:

- Purpose: Corrects for bulk effect and nonspecific binding. [22]

- Action: Subtract the sensorgram obtained from a "blank" surface (an empty or irrelevant protein-coated surface) injected with the analyte solution from the sensorgram of the active ligand surface injected with the same analyte. [22]

- Methods: Channel Referencing: Uses dedicated flow channels as blank surfaces. Interspot Referencing: Uses inactive spots immediately adjacent to the active interaction spots, conserving channel space and improving proximity. [22]

Blank Buffer Referencing:

- Purpose: Corrects for baseline drift resulting from ligand surface changes over time. [22]

- Action: Subtract the sensorgram obtained from injecting a blank buffer (or negative control) over the active ligand surface from the analyte injection sensorgram. [22]

- Methods: Injection Referencing: A separate blank buffer injection is performed before the analyte injections. Real-time Double Referencing: A blank buffer is injected in parallel with the analyte injections, providing more accurate drift correction. [22]

Comparative Instrument Performance in Preprocessing

The stability of the baseline is a critical hardware-dependent factor that directly influences the ease and effectiveness of preprocessing. Instruments with lower noise and drift reduce the corrective burden on software algorithms, leading to higher data quality.

Table 1: Instrument Baseline Performance and Data Quality

| Instrument / System | Baseline Noise (RMS) | Baseline Drift | Key Preprocessing & Data Quality Advantages |

|---|---|---|---|

| Reichert SPR Systems [23] | 0.05 μRIU | 0.1 μRIU | Industry-leading low noise and drift for superior signal-to-noise ratio; maximizes data quality for weak interactions and low molecular weight compounds (<100 Da). [23] |

| ProteOn XPR36 [22] | Information Missing | Information Missing | Unique Interspot Referencing and Real-time Double Referencing for superior bulk effect and drift correction without consuming extra flow channels. [22] |

| Biacore Systems (via Genedata) [25] | Information Missing | Information Missing | Unified software platform (Genedata Screener) standardizes preprocessing (alignment, referencing) across different Biacore models (4000, T200, S200), ensuring consistent data processing and reporting. [25] |

| OpenSPR [17] | Information Missing | Information Missing | Provides affordable, benchtop SPR with data quality comparable to industry standards, suitable for obtaining publication-quality binding kinetics. [17] |

Table 2: Experimental Comparison of Derived Kinetic Data

| Kinetic Parameter | OpenSPR [17] | Standard SPR Instrument [17] |

|---|---|---|

| Association Rate (kₒₙ) | 8.18 × 10⁵ M⁻¹s⁻¹ | 8.18 × 10⁵ M⁻¹s⁻¹ |

| Dissociation Rate (kₒff) | 1.25 × 10⁻³ s⁻¹ | 5.61 × 10⁻⁴ s⁻¹ |

| Affinity (K_D) | 1.53 nM | 0.686 nM |

Table 2 Note: This comparison of a protein-protein interaction shows that despite differences in experimental setup (e.g., ligand density), both instruments produced K_D values within the same range and with excellent curve fits, demonstrating that robust preprocessing yields reliable kinetic data across platforms. [17]

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful preprocessing and experimentation depend on the appropriate selection of reagents and materials.

Table 3: Essential Materials for SPR Preprocessing and Assay Development

| Item | Function in Preprocessing & Experimentation |

|---|---|

| Sensor Chips (e.g., Gold, Carboxyl, NTA) [9] | The solid support for immobilizing the ligand. Choosing the correct chemistry (e.g., NTA for his-tagged proteins) is vital for proper ligand orientation and minimizing non-specific binding, which is later corrected via reference subtraction. [9] |

| Running Buffer | The liquid phase that carries the analyte. Its precise composition must be matched with the analyte buffer to minimize the bulk refractive index effect, a major artifact removed during reference subtraction. [9] |

| Reference Surfaces | A sensor surface without the specific ligand or with an irrelevant protein. It is essential for generating the "blank surface reference" sensorgram used to subtract non-specific binding and bulk effects. [22] |

| Regeneration Solution [9] | A buffer used to remove bound analyte from the ligand surface between analysis cycles without damaging the ligand. Complete regeneration is required to maintain a stable baseline and ligand activity across multiple injections. |

| Blocking Additives (e.g., BSA, Tween 20) [9] | Added to buffers to coat the sensor surface and reduce non-specific binding (NSB) of the analyte to non-target sites, thereby reducing the magnitude of the artifact that must be subtracted. |

Baseline alignment and reference subtraction are non-negotiable, foundational steps in SPR data preprocessing. They transform raw, artifact-laden sensorgrams into clean data that accurately reflects the biomolecular interaction of interest. The quality of this preprocessing is a function of both robust software algorithms and high-performance instrument hardware characterized by low baseline noise and drift. By adhering to the detailed protocols and understanding the role of essential materials outlined in this guide, researchers can ensure the generation of high-quality, publication-ready SPR data, thereby advancing research in drug development and molecular biology.

Surface Plasmon Resonance (SPR) is a powerful optical technique that enables the label-free detection and analysis of biomolecular interactions in real-time. The methodology depends on detecting minute changes in the refractive index at a sensor surface where a mobile molecule (analyte) binds to an immobilized molecule (ligand) [26]. The quality of the data generated by SPR instruments directly determines the reliability of the kinetic and affinity constants (such as ka, kd, and KD) derived from these experiments. Among the most critical factors influencing data quality are baseline stability, characterized by drift (RU/s), and the inherent noise level (RU) of the system.

Baseline drift represents the gradual, unwanted change in the response signal over time when no active binding is occurring. It is typically measured in Response Units per second (RU/s). Even minor drift can significantly distort the analysis of binding kinetics, leading to inaccurate determinations of association and dissociation rates. Similarly, system noise, measured in Response Units (RU), defines the random fluctuations in the signal around the baseline. High noise levels can obscure the detection of weak binding signals and reduce confidence in the measured parameters [7] [27]. For researchers, scientists, and drug development professionals, a deep understanding of these metrics is paramount for designing robust experiments, selecting appropriate instrumentation, and ensuring the validity of their conclusions, particularly in critical applications like drug discovery and diagnostic development.

Key Metrics for Quantifying Stability

Definition and Impact of Core Metrics

The evaluation of SPR baseline stability rests on two primary quantitative metrics: noise and drift.

Noise (RU): Noise is the random, high-frequency fluctuation in the SPR signal. It is fundamentally governed by the instrumental design, including the stability of the light source, the efficiency of the detector, and the overall electronic stability. In a well-functioning system, the noise level should be very low, often cited as < 1 RU [7]. Noise determines the smallest detectable signal change; a signal must be significantly larger than the noise level to be measured with confidence [27]. High noise can mask small but biologically significant binding events, such as those involving low molecular weight analytes or low-affinity interactions.

Drift (RU/s): Drift is a slower, directional change in the baseline response. It can be positive (upward) or negative (downward). Drift is often a symptom of experimental or surface preparation issues, such as:

- Insufficient surface equilibration: Newly docked sensor chips or recently immobilized surfaces require time to rehydrate and adjust to the running buffer [7].

- Buffer-related problems: Changing running buffers without proper system priming, using buffers with temperature-dependent dissolved air, or poor buffer hygiene can all introduce drift [7].

- Temperature fluctuations: The SPR signal is highly sensitive to temperature changes, which can cause expansion or contraction in the fluidic system and alter the buffer's refractive index [27].

- Ligand leaching: The gradual loss of immobilized ligand from the sensor surface, especially on capture surfaces, will manifest as a negative drift [28].

The impact of drift on data analysis is profound. During the association phase, drift can lead to an over- or under-estimation of the association rate constant (ka). During the long dissociation phases often required for accurate off-rate measurement, drift can severely distort the curve, leading to incorrect calculation of the dissociation rate constant (kd) and, consequently, the equilibrium constant (KD) [28].

Performance Comparison of SPR Systems

While the provided search results do not contain a direct, side-by-side comparison of noise and drift specifications for commercial SPR platforms, they do offer insights into the performance of different technological approaches. The following table synthesizes quantitative data related to sensitivity and stability from the available literature.

Table 1: Comparative Performance Metrics of SPR Sensor Technologies

| Sensor / System Type | Reported Sensitivity (RIU) | Key Stability/Performance Features | Source / Context |

|---|---|---|---|

| Standard SPR (theoretical benchmark) | Varies by configuration | Noise level < 1 RU recommended for quality data; drift must be minimized for accurate kinetic fitting [7]. | General SPR practice |

| Phase-sensitive SPR with custom CMOS | 3 × 10⁻⁷ RIU (Best) | System versatility allows trading dynamic range for sensitivity; enables multi-point detection for richer kinetic insights [29]. | Research system |

| WS₂/Si₃N₄ multilayer architecture | 2.99 × 10⁻⁵ RIU (LoD) | Engineered to concentrate evanescent field at sensing surface; improved signal strength can enhance stability against noise [30]. | Numerical simulation study |

It is crucial to note that a specification like "frequency resolution" in some instruments (e.g., QCM, which shares some data quality concerns with SPR) can be purely theoretical. The more critical parameters for a real-world measurement are the actual noise and long-term drift, as these determine how many of the digitally resolved decimals are actually significant [27]. When evaluating instruments, researchers should request data on noise and drift measured under conditions that mirror their planned experiments (e.g., temperature, liquid phase).

Experimental Protocols for Assessing Stability

Standardized Protocol for Measuring Noise and Drift

A rigorous assessment of instrument stability is a prerequisite for any high-quality SPR experiment. The following protocol, synthesized from established troubleshooting guides [7], provides a standardized method for quantifying baseline noise and drift.

- Objective: To determine the intrinsic noise level and baseline drift of the SPR instrument under standard operating conditions.

- Materials:

- SPR instrument, primed and calibrated according to manufacturer's instructions.

- Fresh, high-quality running buffer (e.g., HBS-EP or HBS-P), 0.22 µm filtered and thoroughly degassed.

- A clean, equilibrated sensor chip (e.g., CM5), which may be blank or mock-immobilized.

- Procedure:

- System Equilibration: Prime the entire fluidic system with the degassed running buffer. Maintain a constant flow rate (e.g., 30 µL/min) and allow the system to stabilize until the baseline response shows no visible directional drift. This may take from 30 minutes to several hours, or even overnight for new chips [7].

- Data Collection for Drift: Once stabilized, record the baseline signal for a minimum of 15-30 minutes without any injections. The baseline should be as flat as possible.

- Data Collection for Noise: Program a series of at least three dummy injections where running buffer is injected over the active and reference flow cells. Use the same injection volume and contact time as planned for analyte experiments. Observe the sensorgram after each injection [7].

- Data Analysis:

- Drift (RU/s): In the stable baseline region from Step 2, perform a linear regression on the response over time. The slope of this line is the drift rate. For high-quality kinetics, drift should be minimal and consistent across all flow cells.

- Noise (RU): During the flat baseline regions of the dummy injections (excluding the injection and bulk shift regions), calculate the standard deviation of the response. This value represents the system's noise level. As noted, this should ideally be < 1 RU [7].

Mitigation Strategies and Experimental Design

When excessive noise or drift is identified, a systematic approach to troubleshooting is required. Furthermore, specific experimental design strategies can proactively minimize their impact on data.

Addressing Drift:

- Ensure Proper Equilibration: Always equilibrate the system with running buffer until the baseline is stable. Incorporate at least three "start-up cycles" that mimic experimental cycles but inject buffer instead of analyte [7].

- Maintain Buffer Hygiene: Prepare fresh buffers daily, filter and degas them, and avoid adding fresh buffer to old stocks. Prime the system thoroughly after any buffer change [7].

- Verify Surface Stability: If drift persists on a particular surface, it may indicate inadequate ligand stability or immobilization chemistry.

Minimizing Impact via Referencing:

- Double Referencing: This is a critical data processing technique. First, subtract the signal from a reference flow cell (which lacks the ligand) from the active flow cell signal. This corrects for bulk refractive index shifts and some instrument drift. Second, subtract the average response from several blank (buffer) injections. This corrects for any systematic differences between the reference and active surfaces and further reduces drift-related artifacts [7].

Diagram: Experimental workflow for assessing and ensuring SPR baseline stability

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key reagents and materials crucial for conducting SPR experiments with high baseline stability, as derived from the methodologies cited [26].

Table 2: Essential Research Reagent Solutions for SPR Experiments

| Reagent / Material | Function / Purpose | Specific Example / Note |

|---|---|---|

| Sensor Chips (CM5) | Provides the gold film surface and a covalently attached hydrogel matrix (e.g., carboxymethylated dextran) for ligand immobilization [26]. | Research-grade CM5 chip is commonly used. |

| HBS Buffers (HBS-N, HBS-EP, HBS-P) | Serve as the running buffer to maintain constant pH and ionic strength. HBS-EP includes EDTA and surfactant P20 to reduce non-specific binding [26]. | 0.15 M NaCl, 0.01 M HEPES, pH 7.4. Surfactant P20 is critical. |

| Amine Coupling Reagents (NHS, EDC) | Activates the carboxyl groups on the sensor chip surface to enable covalent immobilization of ligands containing primary amines [26]. | Part of a standard amine-coupling kit. |

| Ethanolamine | Blocks remaining activated ester groups on the sensor surface after ligand immobilization, preventing non-specific binding in subsequent steps [26]. | Typically used at pH 8.5. |

| Sodium Acetate Buffers | Provides a low-pH environment to facilitate the electrostatic pre-concentration of protein ligands onto the negatively charged sensor chip surface prior to amine coupling [26]. | Various pH (4.0-5.5) to suit different protein isoelectric points. |

| Regeneration Solutions (Glycine, NaOH) | Removes bound analyte from the immobilized ligand without destroying ligand activity, allowing for re-use of the sensor surface for multiple analyte cycles [26]. | Glycine-HCl (pH 1.5-3.0) or 50 mM NaOH. Condition must be optimized. |

| BIAdesorb Solutions | Used for stringent cleaning and sanitization of the instrument's fluidic path and sensor chip to remove accumulated contaminants [28]. | Includes SDS and basic glycine solutions. |

The rigorous quantification of stability through metrics like noise (RU) and drift (RU/s) is not a mere procedural formality but a foundational element of robust SPR research. These metrics directly govern the accuracy of the kinetic and affinity constants that undercritical decisions in drug discovery and diagnostic development. As SPR technology evolves, with new sensor architectures pushing the limits of sensitivity [29] [30], the principles of maintaining a stable baseline remain universally important. By adhering to standardized protocols for stability assessment, employing proactive experimental design—including thorough system equilibration and the mandatory use of double referencing—and understanding the core materials involved, researchers can significantly enhance the quality and reliability of their SPR data, ensuring that their scientific conclusions are built upon a stable and trustworthy foundation.

Leveraging the SPR Database (SPRD) for Proven Buffer and Chip Combinations

In surface plasmon resonance (SPR) research, the pursuit of high-quality data with stable baselines is paramount for generating reliable kinetic parameters. Data quality is profoundly influenced by initial experimental design choices, particularly the selection of sensor chips and buffer compositions. These factors directly impact non-specific binding, mass transport limitations, and baseline stability—core metrics in any rigorous SPR study. Until recently, researchers relied heavily on trial-and-error or institutional knowledge to optimize these conditions. The introduction of the Surface Plasmon Resonance Database (SPRD) marks a significant advancement, offering a systematically curated repository of experimental details from thousands of publications to inform experimental planning with empirically validated conditions.

The SPR Database (SPRD): A Resource for Experimental Planning

The SPR Database (SPRD) is a publicly accessible resource (www.sprdatabase.info) developed to address the critical challenge of optimizing SPR experimental conditions [31]. It contains technical details extracted from 5,140 publications, comprising over 5,500 individual entries of curated SPR experimental data [31] [32]. This database was created because technical details about buffer composition, sensor chip types, and coupling chemistry are typically buried in materials and methods sections of publications and are not easily accessible through conventional search engines or PubMed [31].

The database captures numerous experimental variables for each entry, including [31]:

- Ligand and analyte information: Names, protein tags, and molecular classes

- Sensor chip type: Specific chip models and surfaces

- Immobilization methods: Coupling chemistry and capture techniques

- Buffer conditions: Running buffers and regeneration solutions

- Kinetic parameters: Association rate (ka), dissociation rate (kd), and equilibrium dissociation constants (KD) when available

- Instrument information: SPR platforms used

Each data entry is linked to its original publication through PubMed unique identifier numbers (PMID), allowing researchers to trace back to primary sources [31]. This comprehensive approach enables scientists to leverage collective experimental knowledge to design better experiments, potentially saving significant time and resources typically invested in initial optimization and troubleshooting.

Quantitative Analysis of Common SPR Conditions from the SPRD

Analysis of the SPRD reveals clear patterns in preferred experimental conditions across the research community. The following table summarizes the most frequently used chip types and immobilization methods based on data from 5,140 publications:

Table 1: Most Common SPR Experimental Conditions from SPRD Analysis

| Experimental Factor | Most Prevalent Choice | Alternative Options | Impact on Data Quality |

|---|---|---|---|

| Sensor Chip | CM5 chip (dextran matrix) | C1 chip (no dextran), SA chip (streptavidin coated) | KD values can vary ~3x between CM5 and C1 chips due to matrix effects [31] |

| Immobilization Method | Amine coupling | Biotin-streptavidin capture, antibody-mediated capture | Affinity measurements can vary up to 28x between amine coupling and capture methods [31] |

| Buffer Composition | Phosphate and Tris buffers | HEPES, acetate, and other physiological buffers | KD values can vary significantly (e.g., ~411 μM vs. ~261 μM in different buffers) [31] |

The database analysis demonstrates how specific condition choices can substantially impact experimental outcomes. For instance, the dissociation constant (KD) for Factor H binding to C3b was found to be approximately three times higher when using a CM5 chip (~2.2 μM) compared to a C1 chip (~0.7 μM), even with the same coupling chemistry and buffer conditions [31]. Similarly, immobilization method significantly influences results, as demonstrated by the 28-fold difference in reported KD values for PD-1/PD-L1 interactions when PD-1 was immobilized via amine coupling versus captured on a streptavidin chip [31].

Experimental Design: Leveraging SPRD for Optimal Conditions

Strategic Ligand Immobilization and Chip Selection

The SPRD data underscores the importance of strategic experimental design, beginning with appropriate ligand selection. The smaller binding partner is typically preferred as the ligand to maximize the response signal [9]. For multivalent analytes, using the binding partner with multiple binding sites as the ligand helps prevent artificially low affinity measurements [9]. Existing tags on one binding partner should be considered for capture-based immobilization approaches, which often yield higher ligand activity through proper orientation and binding site accessibility [9].

Sensor chip selection must align with both immobilization strategy and ligand characteristics. The SPRD reveals that while CM5 chips with amine coupling represent the most common approach, numerous alternatives exist for specific applications [31]. The following decision framework illustrates how to leverage SPRD for selecting proven buffer and chip combinations: