Surface Passivation Mechanisms for Perovskite Quantum Dot Electronic Stability: From Fundamentals to Biomedical Applications

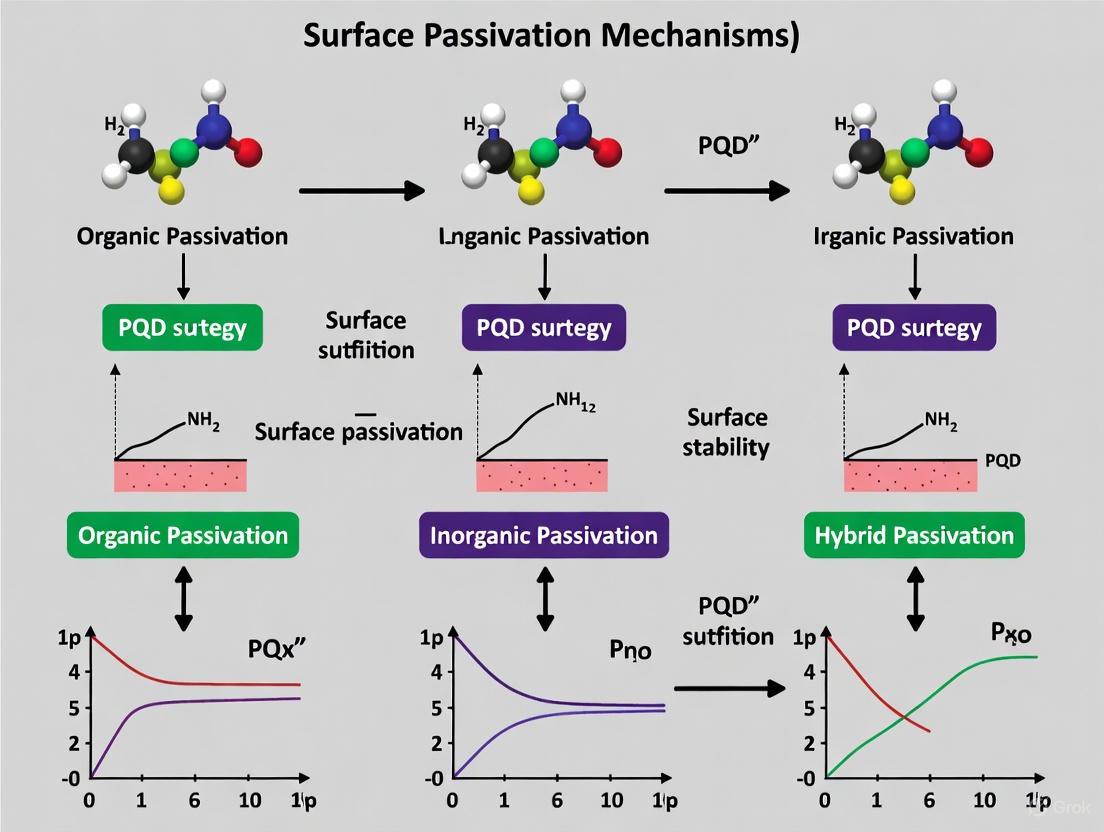

This comprehensive review explores advanced surface passivation strategies that enhance the electronic stability and performance of perovskite quantum dots (PQDs) for optoelectronic and biomedical applications.

Surface Passivation Mechanisms for Perovskite Quantum Dot Electronic Stability: From Fundamentals to Biomedical Applications

Abstract

This comprehensive review explores advanced surface passivation strategies that enhance the electronic stability and performance of perovskite quantum dots (PQDs) for optoelectronic and biomedical applications. Covering foundational defect chemistry, innovative methodological approaches including ligand engineering and hybrid passivation, and troubleshooting for environmental stability, the article synthesizes recent research breakthroughs. It further validates these mechanisms through performance metrics in solar cells, LEDs, and emerging biomedical sensors, providing researchers and drug development professionals with critical insights for developing stable, high-performance PQD-based devices and diagnostic tools.

Understanding PQD Instability: The Critical Role of Surface Defects and Passivation Fundamentals

Fundamental Electronic Structure of Perovskite Quantum Dots

Perovskite Quantum Dots (PQDs) are a class of semiconductor nanocrystals that have garnered significant research interest due to their exceptional optoelectronic properties, which are intrinsically linked to their unique electronic structure. The general formula for lead halide perovskites is APbX3, where A is a cation (e.g., Cs+, MA+) and X is a halide anion (e.g., Br-, I-). The electronic configuration of the Pb2+ ion (6s2) and the hybridization between the Pb s and p orbitals with the halogen p orbitals are responsible for their characteristic optical properties, including high absorption coefficients and tunable bandgaps [1].

The confinement of charge carriers within nanoscale dimensions—the quantum confinement effect—further modulates the electronic band structure, leading to size-dependent photoluminescence. However, the low formation energy for defects, particularly halide vacancies, and the low ion migration energy in the PQD lattice make these materials prone to surface defects [1]. These defects, often appearing as under-coordinated Pb2+ ions or halide vacancies on the crystal surface, create trap states within the bandgap. These mid-gap states act as centers for non-radiative recombination, whereby excited electrons relax back to the valence band without emitting photons, thereby reducing the photoluminescence quantum yield (PLQY) and overall device efficiency [1] [2].

Surface Chemistry and the Imperative for Passivation

The surface chemistry of PQDs is a critical determinant of their stability and performance. The high surface-to-volume ratio of quantum dots means a significant portion of atoms resides on the surface, making them highly reactive. Surface ligands, typically long-chain organic molecules like oleic acid (OA) and oleylamine (OAm), are used during synthesis to control growth and provide colloidal stability. However, these ligands are often dynamically bound and can readily detach during purification or upon exposure to environmental stimuli such as heat, light, or moisture [1]. This ligand loss creates more surface defects and facilitates quantum dot aggregation, accelerating structural degradation.

This inherent instability is a critical bottleneck for practical applications. Consequently, sophisticated surface passivation strategies are required to suppress non-radiative recombination, enhance environmental stability, and enable the development of commercial optoelectronic devices. Passivation aims to coordinate with these under-coordinated surface atoms, eliminating trap states and creating a more robust and optically efficient material.

Advanced Passivation Methodologies and Experimental Protocols

Recent research has focused on developing robust passivation strategies that go beyond conventional ligand capping. Two prominent and effective methodologies are hybrid organic-inorganic passivation and in-situ epitaxial core-shell structuring.

Hybrid Organic-Inorganic Passivation of Lead-Free PQDs

This protocol details the synthesis of stable, lead-free Cs3Bi2Br9 PQDs using a hybrid passivation strategy, as exemplified in the search results [1].

Experimental Protocol:

- Synthesis of Cs3Bi2Br9 PQDs: A transparent precursor solution is prepared by dissolving Cesium Bromide (CsBr, 0.2 mmol) and Bismuth Tribromide (BiBr3, 0.2 mmol) in 5 mL of Dimethyl Sulfoxide (DMSO) under stirring. Oleic acid (OA, 0.5 mL) and oleylamine (OAm, 50 µL) are added as initial capping ligands [1].

- Antisolvent Crystallization: The PQDs are crystallized using an antisolvent method, where the precursor solution is rapidly injected into a poor solvent, inducing instantaneous nucleation and growth.

- Organic Passivation with DDAB: Didodecyldimethylammonium bromide (DDAB) is added to the PQD solution. The DDA+ cation has a strong affinity for halide anions (Br⁻), effectively passivating surface defects. The concentration of DDAB is varied (e.g., 1 mg, 5 mg, 10 mg) to optimize the passivation effect [1].

- Inorganic Encapsulation with SiO₂: To achieve complete encapsulation, a silica (SiO₂) shell is grown on the DDAB-passivated PQDs via the hydrolysis and condensation of Tetraethyl orthosilicate (TEOS, 2.4 mL) added to the solution. This forms a dense, amorphous protective layer [1].

- Purification: The resulting Cs3Bi2Br9/DDAB/SiO₂ PQDs are purified through centrifugation to remove unreacted precursors and byproducts.

Table 1: Key Reagents for Hybrid Passivation Protocol

| Reagent Name | Chemical Function | Role in Passivation Protocol |

|---|---|---|

| Didodecyldimethylammonium bromide (DDAB) | Organic ammonium salt | Passivates surface halide vacancies via strong electrostatic interaction; its relatively short alkyl chains improve surface coverage compared to OA/OAm [1]. |

| Tetraethyl orthosilicate (TEOS) | Silicon alkoxide precursor | Hydrolyzes to form a dense, amorphous SiO₂ inorganic shell, providing a barrier against environmental moisture and oxygen [1]. |

| Oleic Acid (OA) / Oleylamine (OAm) | Long-chain carboxylic acid and amine | Initial ligands to control PQD growth and provide colloidal stability during synthesis [1]. |

In-Situ Epitaxial Core-Shell PQD Passivation

This advanced strategy involves the integration of pre-synthesized core-shell PQDs during the fabrication of a bulk perovskite film, enabling defect passivation at the grain boundaries [2].

Experimental Protocol:

- Synthesis of Core-Shell PQDs: Methylammonium lead bromide (MAPbBr3) core PQDs are synthesized via a colloidal hot-injection method. A precursor solution containing MABr and PbBr2 in DMF with oleylamine and oleic acid is rapidly injected into hot toluene (60°C) [2].

- Shell Growth: A precursor solution of tetraoctylammonium bromide (t-OABr) and PbBr2 is subsequently injected into the reaction mixture. This leads to the epitaxial growth of a wider-bandgap tetraoctylammonium lead bromide (tetra-OAPbBr3) shell around the MAPbBr3 core, forming a core-shell structure (MAPbBr3@tetra-OAPbBr3) [2].

- Purification: The core-shell PQDs are purified via centrifugation (6000 rpm for 10 min, then 15,000 rpm with isopropanol) and redispersed in chlorobenzene [2].

- In-Situ Integration into Perovskite Solar Cells: During the spin-coating of a bulk perovskite film (e.g., for a solar cell), a controlled volume (200 µL) of the core-shell PQD solution (in chlorobenzene at an optimized concentration of 15 mg/mL) is dynamically applied as an antisolvent during the final stage of spinning [2].

- Film Formation: This process enables the simultaneous crystallization of the bulk perovskite film and the incorporation of the core-shell PQDs at the grain boundaries and surfaces, where they passivate defects epitaxially [2].

Table 2: Key Reagents for Core-Shell Passivation Protocol

| Reagent Name | Chemical Function | Role in Passivation Protocol |

|---|---|---|

| Tetraoctylammonium Bromide (t-OABr) | Organic ammonium salt | Forms a wider-bandgap shell layer around the core PQD, enhancing carrier confinement and suppressing non-radiative recombination at the PQD surface [2]. |

| Methylammonium Bromide (MABr) | Organic perovskite precursor | Forms the light-absorbing core of the PQD with a specific bandgap [2]. |

| Lead Bromide (PbBr2) | Metal halide perovskite precursor | Provides the Pb²⁺ and Br⁻ ions for the crystal lattice of both the core and shell [2]. |

| Chlorobenzene | Organic solvent | Serves as the antisolvent and dispersion medium for the core-shell PQDs during the in-situ integration step [2]. |

Quantitative Analysis of Passivation Efficacy

The success of these passivation strategies is quantitatively evaluated through material characterization and device performance metrics.

Table 3: Quantitative Performance Enhancement from Passivation

| Performance Parameter | Unpassivated/Control Device | Passivated Device | Enhancement & Stability |

|---|---|---|---|

| Power Conversion Efficiency (PCE) | 19.2% (Control PSC) [2] | 22.85% (Core-Shell PQD PSC) [2] | Absolute increase of 3.65% [2] |

| Open-Circuit Voltage (VOC) | 1.120 V [2] | 1.137 V [2] | Improved charge extraction [2] |

| Short-Circuit Current Density (JSC) | 24.5 mA/cm² [2] | 26.1 mA/cm² [2] | Enhanced light harvesting [2] |

| Fill Factor (FF) | 70.1% [2] | 77.0% [2] | Reduced recombination losses [2] |

| Photoluminescence Quantum Yield (PLQY) | Implicitly low due to defects [1] | Significantly increased [1] | Suppressed non-radiative decay [1] |

| Long-Term Stability (PCE retention) | ~80% after 900 hours [2] | >92% after 900 hours [2] | Superior environmental robustness [2] |

| Long-Term Stability (Lead-free PQD SC) | Not specified | >90% after 8 hours [1] | 95.4% normalized performance retention [1] |

Characterization Techniques for Verification

Rigorous characterization is essential to validate the electronic and structural improvements from passivation.

- Photoluminescence (PL) Spectroscopy: Measures emission intensity and wavelength, directly indicating the reduction in non-radiative traps via increased PL intensity [1].

- Time-Resolved PL (TRPL): Quantifies the photoluminescence lifetime. An increase in average lifetime after passivation indicates a reduction in trap-assisted recombination, as charge carriers recombine radiatively over a longer period [1] [2].

- Transmission Electron Microscopy (TEM): Provides direct visualization of the PQD morphology, size distribution, and, in core-shell structures, the evidence of a shell layer. It can also show the integration of PQDs at grain boundaries in bulk films [1] [2].

- Temperature-Dependent PL: Analyses exciton-phonon interactions and the dynamics of radiative recombination across a temperature range (e.g., 20-300 K), offering insights into the thermal stability of the passivated PQDs [1].

The electronic structure and surface chemistry of PQDs are inextricably linked. While their innate electronic configuration grants remarkable optoelectronic properties, their surface instability remains a critical challenge. The development of advanced passivation mechanisms—such as the synergistic hybrid organic-inorganic coating and the in-situ epitaxial core-shell integration—provides a robust pathway to mitigate surface defects. These strategies effectively suppress non-radiative recombination, enhance environmental stability, and boost device performance, as quantitatively demonstrated in both light-emitting and photovoltaic applications. Mastering surface chemistry is, therefore, the cornerstone for unlocking the full potential of perovskite quantum dots in next-generation optoelectronic technologies.

Diagrams

Diagram 1: Hybrid Organic-Inorganic Passivation Mechanism

Diagram 2: In-Situ Epitaxial Core-Shell Passivation Workflow

Diagram 3: Surface Defect & Passivation Logic

The operational stability and performance of halide perovskite quantum dots (PQDs) are predominantly governed by the dynamics of intrinsic defects. This whitepaper provides an in-depth technical analysis of three core defect types—halide vacancies, ion migration, and ligand detachment—that compromise the electronic and structural integrity of PQDs. Within the broader context of surface passivation mechanisms, we elucidate the fundamental origins and consequences of these defects, supported by quantitative characterization data. The document further details advanced experimental protocols for defect mitigation and features a synthesized toolkit of research reagents essential for stability enhancement. By integrating defect theory with practical experimentation, this guide serves as a comprehensive resource for researchers and scientists dedicated to advancing the commercialization of stable perovskite-based optoelectronics.

Metal halide perovskite quantum dots (PQDs) have emerged as a revolutionary class of semiconducting materials for optoelectronic applications, including light-emitting diodes (LEDs), solar cells, and photodetectors. Their appeal lies in exceptional properties such as high photoluminescence quantum yields (PLQY), tunable bandgaps, and cost-effective solution processability [3] [4]. However, the path to commercial viability is obstructed by intrinsic material instability, which is directly linked to defect chemistry.

The ionic nature of perovskite crystals and their high surface-to-volume ratio make them susceptible to specific defect types that act as non-radiative recombination centers, degrading device performance and operational lifetime [5]. This whitepaper isolates and examines three critical defect pathways:

- Halide Vacancies: The most common intrinsic point defect due to low formation energy.

- Ion Migration: A bulk and interface degradation process driven by vacancy movement.

- Ligand Detachment: A surface-specific instability leading to nanoparticle aggregation and defect formation.

Understanding and mitigating these defects through sophisticated surface passivation mechanisms constitutes a central theme in modern perovskite research. This document provides a foundational framework for this ongoing scientific endeavor, offering a detailed guide to the nature, analysis, and control of these debilitating defects.

Defect Fundamentals: Mechanisms and Impacts

Halide Vacancies

Formation Mechanism: Halide vacancies (VX) are the most prevalent point defects in lead halide perovskites. Their formation is thermodynamically favored due to a low energy barrier for creation, estimated to be as low as 0.3 eV for iodide vacancies in MAPbI3 [5]. This low formation energy is a direct consequence of the ionic crystal lattice and weak bond strength, particularly for Pb-I bonds. During synthesis or under operational stress (light, heat), halide ions can be displaced from their lattice sites, creating vacancies.

Impact on Material Properties: These vacancies create deep-level trap states within the bandgap. These states act as centers for non-radiative recombination, where photo-generated electrons and holes recombine without emitting light, thereby quenching photoluminescence and reducing the PLQY [5]. This directly diminishes the efficiency of light-emitting devices and the open-circuit voltage of solar cells. Furthermore, halide vacancies serve as the primary initiation points for the more macroscale degradation process of ion migration.

Ion Migration

Driving Forces and Pathways: Ion migration, particularly of halide ions (I⁻, Br⁻) and their vacancies, is a pronounced phenomenon in perovskite materials. Driven by electric fields, concentration gradients, or light soaking, these ionic species can move through the grain boundaries, along surfaces, and within the bulk lattice [6] [7]. The mobility is significantly higher under illumination, as light "softens" the perovskite lattice, reducing the activation energy for ion movement [7].

Consequences for Device Performance: The migration of ions leads to several detrimental effects:

- Hysteresis in J-V Curves: The redistribution of ions modifies the internal electric field, causing the current-voltage characteristics of solar cells to depend on the voltage scan direction and rate [8].

- Phase Segregation: In mixed-halide perovskites, ion migration can lead to halide segregation, forming iodide-rich and bromide-rich domains, which alters the bandgap and leads to unstable emission spectra [4].

- Interface Degradation: Accumulation of migrated ions at interfaces with charge transport layers (e.g., TiO2, Spiro-OMeTAD) can form insulating layers, impede charge extraction, and accelerate non-radiative recombination [8] [9].

- Self-Passivation vs. Degradation: Paradoxically, a limited degree of ion migration can enable "self-passivation," where mobile ions relocate to neutralize interface defects and relax strain, improving performance over time. However, unbridled migration ultimately leads to irreversible degradation, such as electrode corrosion or film cracking [6] [7].

Ligand Detachment

Origin and Mechanism: Colloidal PQDs are stabilized in solution and as solid films by surface-bound organic ligands, such as oleic acid (OA) and oleylamine (OAm). These long-chain ligands possess a bent molecular geometry due to double bonds, resulting in low packing density and steric hindrance on the PQD surface [5]. This leads to weak, dynamic binding. During mandatory purification steps (using polar anti-solvents like methyl acetate) or upon exposure to environmental stimuli (heat, light), these ligands can readily detach.

Downstream Effects: Ligand detachment has two primary negative outcomes:

- Surface Defect Formation: The loss of a ligand exposes under-coordinated Pb²⁺ ions on the PQD surface, creating highly efficient trap states for non-radiative recombination [5].

- PQD Aggregation and Ostwald Ripening: The loss of steric protection allows PQDs to aggregate. Furthermore, it can facilitate Ostwald ripening, where larger particles grow at the expense of smaller ones, leading to a broadened size distribution and loss of quantum confinement effects [5].

Table 1: Summary of Common Defect Types in Halide Perovskite Quantum Dots

| Defect Type | Primary Location | Formation Cause | Key Consequences | Characterization Techniques |

|---|---|---|---|---|

| Halide Vacancies | Bulk & Surface | Low formation energy, synthesis conditions | Non-radiative recombination, initiation of ion migration | Thermal Admittance Spectroscopy, DFT Simulations |

| Ion Migration | Grain boundaries, interfaces | Electric field, light, heat gradients | J-V hysteresis, phase segregation, interface degradation | Hysteresis Index (HI), EIS, TOF-SIMS |

| Ligand Detachment | PQD Surface | Weak binding energy, purification, external stimuli | Surface traps, aggregation, reduced PLQY | FTIR, NMR, TGA, TEM |

Quantitative Characterization of Defects

Quantifying defect density and ion migration strength is essential for evaluating the efficacy of any passivation strategy. The following table compiles key metrics and methods used in the field.

Table 2: Quantitative Metrics for Defect and Ion Migration Characterization

| Parameter | Description | Measurement Technique | Typical Values/Notes |

|---|---|---|---|

| Hysteresis Index (HI) | Quantifies ion migration-induced J-V curve distortion in solar cells. | Current-Voltage (J-V) measurements at different scan rates. | HI is calculated as (PCE_reverse - PCE_forward) / PCE_reverse. A lower HI indicates suppressed ion migration [8]. |

| Ion Migration Resistance (Rion) | Resistance to ion movement within the perovskite film. | Electrochemical Impedance Spectroscopy (EIS). | Measured in MΩ (dark) or kΩ (light). Rion increases with bromide content due to stronger Pb-Br bonds [7]. |

| Photoluminescence Quantum Yield (PLQY) | Ratio of photons emitted to photons absorbed. | Integrating sphere with a calibrated spectrometer. | Fresh PQD films can have PLQY >80%. Defects cause significant drops. Passivation can restore PLQY from ~22% to >50% [5]. |

| External Quantum Efficiency (EQE) | Percentage of charge carriers collected per incident photon. | Spectral response measurement under monochromatic light. | For blue PeLEDs, EQEmax remains in the 10-15% range, limited by defect density [10]. |

Experimental Protocols for Defect Mitigation

This section outlines detailed methodologies for key experiments aimed at understanding and mitigating core defects in PQDs.

Protocol: Light-Soaking Treatment to Activate Self-Passivation

Objective: To mobilize ions post-fabrication to passivate interfacial defects and relax strain, thereby enhancing device performance and reproducibility [6] [7].

- Device Fabrication: Fabricate perovskite solar cells using your standard procedure (e.g., triple-cation perovskite

Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3). - Initial Characterization: Measure the current-density voltage (J-V) characteristics and record the baseline performance parameters (PCE, Voc, Jsc, FF).

- Light-Soaking Intervention: Immediately after fabrication, subject the devices to illumination with standard AM 1.5G simulated sunlight at an intensity of 100 mW cm⁻². The typical duration for this treatment is 10 minutes, performed under ambient atmospheric conditions.

- Aging: After light soaking, store the devices in the dark under controlled, dry conditions (e.g., in a dry air environment at room temperature) for a defined aging period (e.g., 7 days).

- Post-Treatment Analysis: Re-measure the J-V characteristics. Compare parameters with the fresh devices. Expected results include an increase in open-circuit voltage (Voc) and fill factor (FF), indicating reduced interfacial recombination. Confirm the morphological changes using Scanning Electron Microscopy (SEM) to observe grain growth and Photoluminescence (PL) spectroscopy to observe enhanced emission intensity.

Protocol: Surface Passivation via Ligand Exchange

Objective: To replace weakly bound native ligands (OA/OAm) with stronger-binding alternatives to suppress ligand detachment and passivate surface defects [5].

- PQD Synthesis: Synthesize CsPbI3 PQDs using the standard hot-injection or ligand-assisted reprecipitation (LARP) method with OA and OAm as ligands.

- Purification: Precipitate the synthesized PQDs by adding a polar anti-solvent (e.g., methyl acetate) and isolate them via centrifugation. This step removes excess precursors and ligands but also initiates ligand detachment.

- Post-Treatment Passivation: Re-disperse the purified PQD pellet in a non-polar solvent (e.g., hexane or toluene). Add a solution of the new passivating ligand (e.g., 2-aminoethanethiol (AET) in the same solvent). The thiol (-SH) group in AET has a strong affinity for Pb²⁺, facilitating binding.

- Reaction and Purification: Stir the mixture for a set time to allow complete ligand exchange. Re-purify the passivated PQDs by adding an anti-solvent and centrifuging to remove the displaced ligands.

- Validation: Characterize the passivated PQDs.

- FTIR/NMR: Confirm the chemical replacement of OA/OAm with the new ligand.

- PLQY Measurement: A significant increase in PLQY (e.g., from 22% to 51%) confirms effective surface defect passivation [5].

- Stability Test: Monitor PL intensity under continuous UV illumination or water exposure. AET-passivated PQDs can maintain >95% of initial PL intensity after 120 min of UV, demonstrating superior stability.

Protocol: Interface Engineering with a Passivation Interlayer

Objective: To insert a thin material layer between the perovskite and charge transport layer to suppress ion migration and reduce interfacial recombination [9].

- Substrate Preparation: Clean and prepare the transparent conductive electrode (e.g., ITO) with the deposited electron transport layer (e.g., compact TiO2).

- Interlayer Deposition: Deposit a thin layer of the passivation material (e.g., BiI3) onto the ETL. This can be achieved via solution processing (spin-coating) or thermal evaporation. The target thickness is critical; for BiI3, a ~40 nm layer is optimal.

- Perovskite Deposition: Deposit the perovskite absorber layer (e.g., MAPbI3 or MAGeI3) directly on top of the BiI3 interlayer using your standard method (e.g., spin-coating).

- Device Completion: Continue with the fabrication of the remainder of the solar cell (e.g., deposit the hole transport layer (Spiro-OMeTAD) and metal electrodes).

- Device Analysis:

- J-V Measurement: Quantify the improvement in power conversion efficiency (PCE), fill factor (FF), and hysteresis index. Simulations show PCE can increase from 19.28% to 20.30% for MAPbI3 with a BiI3 interlayer [9].

- Impedance Spectroscopy: Measure the ion migration resistance (Rion) to confirm the suppression of ionic motion.

- SCAPS-1D Simulation: Use software like SCAPS-1D to model the band alignment and understand the role of the interlayer in enhancing hole extraction and blocking ion migration.

Visualization of Defect Dynamics and Mitigation

The following diagrams, generated using Graphviz DOT language, illustrate the core defect pathways and a key mitigation strategy.

Diagram 1: Defect formation pathways and consequences in PQDs.

Diagram 2: Experimental workflow for surface passivation via ligand exchange.

The Scientist's Toolkit: Key Research Reagents

This table lists essential materials and their functions for researching and mitigating defects in perovskite quantum dots.

Table 3: Research Reagent Solutions for PQD Defect Studies

| Reagent / Material | Function / Application | Key Mechanism / Note |

|---|---|---|

| 2-Aminoethanethiol (AET) | Surface passivating ligand for PQDs | Strong bidentate binding to under-coordinated Pb²⁺ via thiol group, improving PLQY and moisture resistance [5]. |

| Bismuth Iodide (BiI3) | Interfacial passivation layer | Deposited between perovskite and HTL to enhance hole extraction, passivate defects, and suppress ion migration [9]. |

| Oleic Acid (OA) / Oleylamine (OAm) | Native surface ligands for synthesis | Standard long-chain ligands for colloidal PQD synthesis. Their weak binding and steric hindrance necessitate post-synthetic exchange [5]. |

| Cesium Lead Halide (CsPbX3) | Model PQD system | The benchmark all-inorganic PQD for fundamental defect studies due to its well-defined chemistry and commercial availability [3] [5]. |

| Triple Cation Perovskite | Thin-film absorber for solar cells | Composition (Cs/MA/FA) with optimized I/Br ratio balances ion mobility for self-passivation and stability [6] [7]. |

The Impact of Surface Defects on Non-Radiative Recombination and PLQY

In perovskite quantum dots (PQDs), surface defects are not merely imperfections but central determinants of optoelectronic efficiency. These defects, primarily undercoordinated lead ions and halide vacancies, create mid-gap trap states that facilitate non-radiative recombination pathways, directly competing with radiative processes and diminishing photoluminescence quantum yield (PLQY) [1] [11]. The relationship between surface integrity and luminescence efficiency forms a critical research frontier in perovskite optoelectronics, as stabilizing high PLQY is imperative for commercial applications in lighting, displays, and photovoltaics [12] [13]. This technical guide examines the mechanistic role of surface defects in non-radiative recombination dynamics, quantitative correlations with PLQY, and advanced passivation strategies that collectively underpin the development of stable, high-performance PQD devices.

Fundamental Mechanisms: From Surface Defects to Performance Loss

Atomic Origins of Surface Defects

The soft ionic lattice of lead halide perovskites predisposes them to facile defect formation, with particularly high densities at nanocrystal surfaces where the periodic atomic arrangement terminates [13]. Key surface defects include:

- Undercoordinated Pb²⁺ ions: Resulting from incomplete ligand coverage or halide vacancies, these Lewis acid sites create deep trap states that strongly localize charge carriers [14] [13].

- Halide vacancies: The low formation energy of bromide and iodide vacancies makes them the most prevalent ionic defects, generating shallow electron traps that facilitate ion migration [1] [11].

- Interstitial defects: Migrated ions can occupy interstitial positions, creating complex defect clusters that further enhance non-radiative recombination [11].

These defects introduce electronic states within the bandgap that serve as stepping stones for non-radiative recombination, effectively short-circuiting the luminescence process.

Non-Radiative Recombination Pathways

Non-radiative recombination occurs primarily through Shockley-Read-Hall (SRH) mechanisms wherein trap states sequentially capture electrons and holes, releasing energy as phonons (heat) rather than photons [11]. The kinetics of this process are governed by:

- Trap-assisted recombination: Defect states with energy levels near the mid-gap are particularly efficient recombination centers due to their approximately equal capture cross-sections for electrons and holes [11].

- Auger recombination: Under high carrier injection, the energy from electron-hole recombination can transfer to a third carrier, though this mechanism is less significant at low injection densities typical for LED operation [11].

- Surface recombination velocity: The rate at which carriers recombine at surfaces depends on both trap density and carrier diffusion rates to the surface [1].

The quantitative relationship between defect density (Nt) and PLQY can be described by:

[ \text{PLQY} = \frac{kr}{kr + k{nr} + kt} ]

where (kr) is the radiative recombination rate, (k{nr}) is the intrinsic non-radiative rate, and (k_t) is the trap-assisted recombination rate proportional to Nt [11].

Quantitative Correlations: Defect Density and Optoelectronic Performance

Direct Relationships Between Defects and Efficiency Metrics

Advanced characterization techniques have established quantitative correlations between specific defect types and performance parameters. Positron annihilation spectroscopy (PAS) has revealed that low-electron-density defects, particularly those characterized by long positron lifetimes (τ3), exhibit a strong inverse correlation with photocatalytic efficiency and photocurrent response [15]. Systematic studies on Na₀.₅Bi₂.₅Ta₂O₉ nanosheets demonstrated that reducing the concentration of these specific defects directly enhanced superoxide radical generation rates and charge separation efficiencies [15].

In photovoltaic devices, non-radiative recombination losses directly manifest in reduced open-circuit voltage (VOC), with the voltage deficit (ΔV = VOC,SQ - VOC,measured) providing a quantitative measure of trap-mediated recombination [11]. High-performing perovskite solar cells with minimized defect densities have achieved ΔV values below 0.4 V, approaching the theoretical limits for their bandgaps [11].

Table 1: Quantitative Impact of Surface Defects on Optoelectronic Performance

| Defect Type | Characterization Method | Impact on PLQY | Impact on Device Efficiency | Reference |

|---|---|---|---|---|

| Undercoordinated Pb²⁺ | XPS, FTIR | Reduction from ~80% to <30% | PCE decrease from 22.8% to 19.2% | [2] [13] |

| Halide Vacancies | PAS, TRPL | 40-60% reduction | 15-25% relative PCE loss | [1] [15] |

| Low-electron-density defects | PAS (τ3 lifetime) | Not quantified | 30-50% photocatalysis efficiency loss | [15] |

| Surface Pb-Br defects | PLQY measurements | Increase from 49.6% to 58.3% after passivation | Color gamut to 125.3% NTSC for displays | [13] |

Long-Term Stability and Defect Evolution

The dynamic nature of surface defects under environmental stressors creates complex degradation pathways. Remarkably, in some cases, environmental exposure can induce beneficial surface transformations. CsPbBr₃ PQD glass exposed to ambient air for four years exhibited a spontaneous increase in PLQY from 20% to 93%, attributed to moisture-assisted formation of a PbBr(OH) passivating layer that reduced surface recombination centers [12].

However, more typically, defective surfaces accelerate degradation through:

- Ion migration: Surface defects serve as initiation points for halide migration, leading to phase segregation in mixed-halide perovskites [11].

- Environmental ingress: Defect sites provide pathways for moisture and oxygen penetration, accelerating decomposition [1] [12].

- Ligand desorption: Incompletely passivated surfaces experience progressive ligand loss, creating new undercoordinated sites [1] [13].

Table 2: Defect Passivation Strategies and Performance Outcomes

| Passivation Approach | Mechanism | PLQY Improvement | Stability Enhancement | Application |

|---|---|---|---|---|

| DDAB/SiO₂ hybrid coating | Organic ligand passivation + inorganic encapsulation | Not quantified | >90% efficiency retention after 8 hours | Lead-free Cs₃Bi₂Br₉ PQDs [1] |

| SB3-18 surfactant + Mesoporous Silica | Sulfonate-Pb²⁺ coordination + matrix encapsulation | 49.6% → 58.3% | 95.1% PL intensity retention after water resistance test | CsPbBr₃ QDs for displays [13] |

| PEAI + EHACl complementary passivation | Vacancy healing + Lewis acid base passivation | Not quantified | Enhanced operational and thermal stability | Inverted PSCs (24.6% PCE) [14] |

| Core-shell MAPbBr₃@tetra-OAPbBr₃ PQDs | Epitaxial interface + energy funneling | Not quantified | >92% PCE retention after 900 hours | Perovskite solar cells [2] |

| Four-year air exposure | Moisture-induced PbBr(OH) passivation layer | 20% → 93% | Exceptional long-term stability | CsPbBr₃ PQD glass [12] |

Experimental Methodologies for Defect Analysis and Passivation

Synthesis of Passivated Perovskite Quantum Dots

Organic-Inorganic Hybrid Passivation of Cs₃Bi₂Br₉ PQDs [1]:

- Procedure: Lead-free Cs₃Bi₂Br₉ PQDs were synthesized via antisolvent method using DMSO as solvent. Didodecyldimethylammonium bromide (DDAB) in varying concentrations (1-10 mg) was introduced for organic passivation, followed by inorganic SiO₂ coating via hydrolysis of tetraethyl orthosilicate (TEOS, 2.4 mL).

- Key Parameters: DDAB concentration optimization critical to balance passivation efficacy and potential aggregation. TEOS hydrolysis time controls SiO₂ shell thickness.

- Characterization: TEM analysis confirmed uniform quasispherical nanoparticles (~12 nm) with core-shell structure. PL spectroscopy, lifetime measurements, and temperature-dependent PL analyses quantified optical improvements.

In Situ Epitaxial Quantum Dot Passivation for Solar Cells [2]:

- Procedure: MAPbBr₃@tetra-OAPbBr₃ core-shell PQDs were synthesized via colloidal approach. Core precursor (MABr/PbBr₂ in DMF with oleylamine/oleic acid) injected into heated toluene, followed by shell precursor (t-OABr/PbBr₃) injection. Purified PQDs (15 mg/mL concentration) integrated during antisolvent-assisted crystallization of perovskite films.

- Key Parameters: Precise temperature control (60°C) during nanoparticle growth. Centrifugation at 6000 rpm for 10 minutes, then 15,000 rpm with isopropanol for refinement.

- Characterization: Structural analysis confirmed epitaxial compatibility between PQDs and host perovskite matrix. Device performance showed PCE increase from 19.2% to 22.85%.

Defect Characterization Techniques

Photoluminescence Spectroscopy [1] [12] [13]:

- Time-Resolved PL (TRPL): Measures carrier lifetime; multi-exponential decay fitting distinguishes surface versus bulk recombination.

- Temperature-Dependent PL: Reveals exciton-phonon interactions and trap state distributions across 20-300 K range.

- PL Quantum Yield (PLQY): Absolute measurement of radiative efficiency using integrating spheres.

Positron Annihilation Spectroscopy (PAS) [15]:

- Principle: Detects low-electron-density defects through positron lifetime measurements. Longer τ3 lifetime corresponds to larger vacancy-type defects.

- Procedure: Positron source (²²Na) embedded between sample layers; lifetime spectra deconvoluted into τ1 (monovacancies), τ2 (vacancy clusters), and τ3 (low-electron-density voids) components.

X-ray Photoelectron Spectroscopy (XPS) [16] [13]:

- Application: Identifies chemical states and coordination environments of surface atoms. Pb 4f core-level shifts indicate undercoordinated Pb²⁺ sites.

- Procedure: Surface irradiation with monochromatic X-rays; kinetic energy analysis of emitted photoelectrons. Coordination changes monitored after passivation treatments.

Visualization of Defect Dynamics and Passivation Mechanisms

Defect-Mediated Non-Radiative Recombination Pathways

Multimodal Defect Passivation Strategy Workflow

The Scientist's Toolkit: Research Reagents and Materials

Table 3: Essential Research Reagents for Surface Passivation Studies

| Reagent/Material | Chemical Function | Application Example | Performance Impact |

|---|---|---|---|

| Didodecyldimethylammonium bromide (DDAB) | Surface ligand passivation of halide vacancies | Cs₃Bi₂Br₉ PQD stabilization [1] | Enhanced environmental stability and charge transport |

| Tetraethyl orthosilicate (TEOS) | SiO₂ precursor for inorganic encapsulation | Core-shell PQD formation [1] | Barrier against moisture/oxygen ingress |

| Sulfonic acid-based surfactants (SB3-18) | Lewis base coordination with undercoordinated Pb²⁺ | CsPbBr₃ QD passivation [13] | PLQY increase from 49.6% to 58.3% |

| Phenylethylammonium iodide (PEAI) | 2D/3D interface reconstruction + vacancy healing | Inverted PSC passivation [14] | Champion PCE of 24.6% |

| Ethylhydrazinoacetate hydrochloride (EHACl) | Lewis base passivation of undercoordinated Pb²⁺ | Complementary passivation with PEAI [14] | Enhanced operational and thermal stability |

| Tetraoctylammonium bromide (t-OABr) | Shell precursor for core-shell PQDs | MAPbBr₃@tetra-OAPbBr₃ synthesis [2] | PCE increase from 19.2% to 22.85% |

| Mesoporous silica (MS) templates | Rigid encapsulation matrix | CsPbBr₃-SB3-18/MS composites [13] | 95.1% PL retention after water resistance testing |

Surface defects in perovskite quantum dots fundamentally govern non-radiative recombination dynamics and ultimately determine achievable PLQY and device stability. The quantitative relationships established between specific defect types and performance metrics provide a roadmap for targeted passivation strategies. Multimodal approaches that combine chemical passivation of specific trap states with physical encapsulation against environmental stressors have demonstrated remarkable efficacy in enhancing both efficiency and operational lifetime. Future research directions should focus on developing in situ characterization techniques to monitor defect dynamics under operational conditions, designing multifunctional passivators that simultaneously address multiple defect types, and establishing standardized protocols for quantifying and reporting surface defect densities. The continued refinement of surface passivation strategies represents the most promising pathway toward bridging the gap between laboratory demonstrations and commercial implementation of perovskite quantum dot technologies.

Surface passivation represents a cornerstone of modern materials science, critically determining the performance and longevity of electronic and optoelectronic devices. This foundational process involves the chemical or physical treatment of a material's surface to reduce its reactivity by neutralizing dangling bonds and other defective states. In the specific context of perovskite quantum dots (PQDs) for electronic stability research, effective passivation is not merely a supplementary enhancement but an essential requirement. The high surface-to-volume ratio of PQDs means that a significant proportion of their atoms reside on the surface, making them particularly susceptible to environmental degradation and surface-mediated non-radiative recombination, which severely compromises device performance and operational stability. This guide provides an in-depth examination of both the theoretical underpinnings and practical methodologies of passivation, with a focused application on stabilizing PQDs for advanced electronic applications, synthesizing current research to deliver a actionable framework for researchers and scientists.

Theoretical Foundations of Passivation

At its core, passivation functions through the principle of defect neutralization. Surface defects on materials like perovskites—such as iodide (I⁻) vacancies, suspended Pb²⁺ ions, and under-coordinated atoms—act as trapping sites for charge carriers. These traps facilitate non-radiative recombination, a process where electron-hole pairs recombine without emitting light or performing useful work, thereby dissipating energy as heat and reducing the overall quantum efficiency of the device.

The thermodynamic driving force for passivation is the reduction of the system's surface energy. When a reactive, high-energy surface is treated with passivating agents, it transitions to a more stable, lower-energy state. This state is characterized by a more complete electronic structure and significantly reduced density of mid-gap states within the bandgap, which are the primary pathways for non-radiative recombination. For PQDs, the ionic nature of the crystal lattice and the dynamic binding of surface ligands introduce additional complexity. The passivation layer must not only neutralize defects but also enhance the electronic coupling between individual QDs in a solid film to facilitate efficient charge transport, a critical factor for photovoltaic and light-emitting devices [17].

Key Passivation Strategies for PQDs

Advanced passivation strategies for PQDs have evolved from simple ligand exchange to sophisticated multi-functional approaches. The following sections detail the most effective methodologies.

Multidentate Ligand Passivation

This strategy utilizes molecules with multiple binding sites that can chelate to the PQD surface more strongly than conventional monodentate ligands like oleic acid (OA) and oleylamine (OAm).

- Mechanism: Multidentate ligands, such as ethylene diamine tetraacetic acid (EDTA), function through a "surface surgery treatment." They possess several functional groups that can simultaneously chelate suspended Pb²⁺ ions and passivate I⁻ vacancies. This multi-point binding creates a more robust and comprehensive surface layer [17].

- Additional Benefit: Beyond simple passivation, these ligands can act as crosslinkers between adjacent PQDs, forming a "charger bridge" that improves electronic coupling across the quantum dot solid. This enhances charge carrier transport, which is vital for high-performance solar cells [17].

Organic-Inorganic Hybrid Passivation

This approach combines the defect-passivation capabilities of organic molecules with the superior environmental barrier provided by inorganic materials.

- Mechanism: The process often involves a two-step coating. First, an organic ligand like didodecyldimethylammonium bromide (DDAB) is used to passivate surface defects on lead-free PQDs (e.g., Cs₃Bi₂Br₉). DDAB's strong affinity for halide anions and relatively short alkyl chain length improve coverage and stability. Subsequently, an inorganic silica (SiO₂) shell derived from tetraethyl orthosilicate (TEOS) is formed around the organically-passivated PQD, creating a core-shell structure that offers exceptional protection against moisture, oxygen, and thermal stress [1].

- Outcome: This synergistic strategy results in PQDs with enhanced photoluminescence and significantly extended environmental stability, making them suitable for practical applications in electroluminescence and photovoltaics [1].

In Situ Epitaxial Quantum Dot Passivation

A cutting-edge strategy involves the integration of core-shell PQDs directly during the fabrication of the perovskite active layer.

- Mechanism: Core-shell PQDs, such as those with a methylammonium lead bromide (MAPbBr₃) core and a tetraoctylammonium lead bromide (tetra-OAPbBr₃) shell, are introduced during the antisolvent-assisted crystallization step of a perovskite solar cell. The epitaxial compatibility between the PQD shell and the host perovskite matrix allows the PQDs to embed themselves at grain boundaries and surface defects, effectively passivating these critical failure points [2].

- Advantage: This in situ method ensures that passivation occurs during film formation, leading to a more homogeneous and integrated structure. It suppresses non-radiative recombination at the most vulnerable locations while facilitating more efficient charge transport, thereby boosting both efficiency and device longevity [2].

The logical workflow for selecting and implementing a passivation strategy, informed by the project's primary objectives, is visualized below.

Quantitative Analysis of Passivation Efficacy

The success of a passivation strategy is quantitatively evaluated using a suite of optical, electronic, and stability metrics. The table below summarizes performance data from key studies employing different passivation methods, providing a benchmark for researchers.

Table 1: Quantitative Performance of Passivated Perovskite Devices

| Passivation Method | Device Type | Power Conversion Efficiency (PCE) | Open-Circuit Voltage (Voc) | Key Stability Metric |

|---|---|---|---|---|

| Multidentate Ligand (EDTA) [17] | CsPbI₃ PQD Solar Cell | 15.25% (from 13.67% baseline) | Not Specified | Among highest reported for inorganic PQDSCs |

| Organic-Inorganic (DDAB/SiO₂) [1] | Cs₃Bi₂Br₉ PQD-Si Tandem | 14.85% (from 14.48% baseline) | Not Specified | >90% initial efficiency after 8 hours |

| In Situ Epitaxial QD [2] | MAPbI₃ Solar Cell | 22.85% (from 19.2% baseline) | 1.137 V (from 1.120 V baseline) | >92% initial PCE after 900 hours |

Beyond the parameters in the table, critical quantitative evidence of successful passivation includes:

- Increase in Photoluminescence Quantum Yield (PLQY): A direct indicator of suppressed non-radiative recombination.

- Reduction in Trap State Density (Nt): Measured via techniques like thermal admittance spectroscopy.

- Increase in Charge Carrier Lifetimes: Observed through time-resolved photoluminescence (TRPL) decay measurements.

- Lower Non-Radiative Recombination Losses: Evidenced by a higher quasi-Fermi level splitting and increased Voc in solar cells [17] [2].

Detailed Experimental Protocols

To translate theory into practice, this section provides detailed methodologies for implementing key passivation strategies.

Protocol: Multidentate Ligand Passivation of CsPbI₃ PQDs

This protocol is adapted from the "surface surgery treatment" using EDTA, designed to resurface PQDs for enhanced optoelectronic properties [17].

PQD Film Deposition:

- Synthesize CsPbI₃ PQDs (~12 nm) using the standard hot-injection method and disperse in a non-polar solvent like hexane.

- Deposit the PQD solution onto a substrate via spin-coating or drop-casting to form a solid film.

- Immediately after deposition, immerse the film in methyl acetate (MeOAc) anti-solvent for 30 seconds to remove the original long-chain OA/OAm ligands. This step inevitably creates surface defects.

Surface Surgery Treatment (SST):

- Prepare a saturated solution of EDTA in a compatible solvent (e.g., dimethylformamide - DMF, or isopropanol).

- Drop-cast the EDTA solution directly onto the freshly rinsed PQD solid film.

- Allow the treatment to proceed for 60-120 seconds. During this time, EDTA molecules chelate suspended Pb²⁺ ions and occupy I⁻ vacancies.

- Spin-off the excess solution and gently anneal the film at 70-90°C for 5-10 minutes to remove residual solvent and stabilize the passivation layer.

Protocol: Organic-Inorganic Hybrid Passivation of Cs₃Bi₂Br₉ PQDs

This protocol outlines the stabilization of lead-free PQDs using DDAB and a subsequent SiO₂ coating [1].

DDAB Organic Passivation:

- Synthesize Cs₃Bi₂Br₉ PQDs via the antisolvent method.

- Purify the as-synthesized PQDs to remove excess precursors and weakly bound ligands.

- Redisperse the purified PQDs in a solvent like toluene.

- Add a solution of DDAB (optimally 10 mg) to the PQD dispersion under stirring. The DDAB concentration is critical to prevent aggregation while ensuring full surface coverage.

- Stir the mixture for 1-2 hours to allow DDAB to effectively passivate surface defects.

SiO₂ Inorganic Encapsulation:

- To the DDAB-passivated PQD dispersion, add a controlled volume of tetraethyl orthosilicate (TEOS) (e.g., 2.4 mL) as the silica precursor.

- Catalyze the hydrolysis and condensation of TEOS by introducing a basic catalyst (e.g., ammonium hydroxide).

- Allow the reaction to proceed for several hours to form a dense, amorphous SiO₂ shell around the PQDs.

- Purify the resulting Cs₃Bi₂Br₉/DDAB/SiO₂ core-shell structures via centrifugation and redisperse in an appropriate solvent for device fabrication.

Protocol: In Situ Epitaxial Passivation of Perovskite Solar Cells

This protocol describes the integration of core-shell PQDs during the active layer fabrication of a standard n-i-p PSC [2].

Synthesis of Core-Shell PQDs:

- Prepare a core precursor solution of MABr and PbBr₂ in DMF with oleylamine and oleic acid.

- Prepare a separate shell precursor solution of tetraoctylammonium bromide (t-OABr) and PbBr₂.

- Inject the core precursor into hot toluene to form MAPbBr₃ PQD cores.

- Subsequently, inject the shell precursor into the reaction mixture to form the tetra-OAPbBr₃ shell, resulting in MAPbBr₃@tetra-OAPbBr₃ core-shell PQDs.

- Purify and redisperse the PQDs in chlorobenzene at a precise concentration (e.g., 15 mg/mL).

Device Fabrication with In Situ Passivation:

- Deposit the electron transport layer (e.g., mesoporous TiO₂) on a cleaned FTO substrate.

- Prepare the perovskite precursor solution (e.g., containing PbI₂, FAI, MABr, MACl).

- Deposit the perovskite film using a two-step spin-coating process.

- During the final seconds of the second spin-coating step, dynamically introduce 200 µL of the core-shell PQD solution (in chlorobenzene) as the antisolvent.

- Anneal the films at 100°C for 10 min and then 150°C for 10 min. The PQDs, introduced via the antisolvent, embed epitaxially at grain boundaries and interfaces during crystallization.

The intricate mechanism of multidentate ligand passivation, which underlies one of the protocols, is broken down into its fundamental steps in the following diagram.

The Scientist's Toolkit: Essential Research Reagents

Successful implementation of the aforementioned protocols requires a specific set of high-purity materials. The following table catalogs the essential reagents and their functions in PQD passivation research.

Table 2: Essential Reagents for PQD Passivation Research

| Reagent/Chemical | Function in Passivation | Example Application |

|---|---|---|

| Ethylene Diamine Tetraacetic Acid (EDTA) | Multidentate chelating ligand; removes suspended Pb²⁺ and passivates I⁻ vacancies. | Surface surgery treatment for CsPbI₃ PQDs [17]. |

| Didodecyldimethylammonium Bromide (DDAB) | Organic passivator with strong halide affinity; improves surface coverage and stability. | Primary organic passivation layer for Cs₃Bi₂Br₉ PQDs [1]. |

| Tetraoctylammonium Bromide (t-OABr) | Precursor for forming a wider-bandgap shell around a PQD core. | Shell formation in MAPbBr₃@tetra-OAPbBr₃ core-shell PQDs [2]. |

| Tetraethyl Orthosilicate (TEOS) | Inorganic precursor for forming a protective silica (SiO₂) encapsulation shell. | Hydrolyzed to create a SiO₂ coating on DDAB-passivated PQDs [1]. |

| Methylammonium Bromide (MABr) | Organic cation source for forming the core of hybrid perovskite QDs. | Core formation in MAPbBr₃ QDs [2]. |

| Lead(II) Bromide (PbBr₂) | Metal halide precursor essential for the perovskite crystal structure. | Used in the synthesis of both MAPbBr₃ and CsPbBr₃ PQDs [1] [2]. |

| Oleic Acid (OA) / Oleylamine (OAm) | Standard long-chain ligands for colloidal synthesis and initial stabilization of QDs. | Capping ligands during initial PQD synthesis; partially removed during passivation [17] [1]. |

| Methyl Acetate (MeOAc) | Anti-solvent used to precipitate PQD films and remove original ligands prior to passivation. | Ligand removal and film densification step [17]. |

The journey from fundamental passivation theory to practical implementation is marked by a strategic understanding of defect chemistry and the innovative application of chemical treatments. For perovskite quantum dots, the evolution from simple ligand exchanges to advanced methods like multidentate resurfacing, hybrid organic-inorganic coating, and in situ epitaxial passivation represents a significant leap forward. These strategies directly address the critical challenges of electronic instability and environmental degradation. The quantitative data and detailed protocols provided herein serve as a robust foundation for researchers in the field. Continued refinement of these passivation principles, with a focus on scalability, long-term stability, and lead-free alternatives, will be paramount in translating the exceptional promise of PQDs into commercially viable and durable electronic devices.

Structural degradation describes the gradual deterioration of a material's mechanical properties or a system's load-bearing capacity over time due to various environmental or operational stressors [18]. In the context of surface passivation for perovskite quantum dot (PQD) electronic stability, understanding and mitigating this degradation is paramount. While traditionally associated with large-scale civil infrastructure, the fundamental principles of degradation mechanics—including fatigue, corrosion, and environmental aging—directly parallel the failure mechanisms observed in functional electronic materials. This whitepaper examines these universal degradation challenges, translating structural health monitoring (SHM) methodologies and non-destructive testing (NDT) principles from macro-scale engineering to the nano-scale domain of PQD research. The integration of these advanced assessment techniques provides a robust framework for developing accelerated aging tests and predictive lifetime models essential for PQD commercialization.

Fundamental Degradation Mechanisms

The degradation of materials and structures, from reinforced concrete to perovskite films, is driven by the complex interplay of operational loads and ambient environmental conditions. These factors can be broadly categorized to systematically analyze their individual and synergistic effects.

Table 1: Primary Drivers of Structural Degradation

| Category | Factor | Effect on Material/Structure | Relevance to PQD Stability |

|---|---|---|---|

| Environmental Conditions | Temperature | Induces expansion/contraction, alters material properties [19] | Phase instability, ligand desorption, accelerated chemical reactions. |

| Humidity | Alters material properties through moisture absorption [19] | PQD decomposition, hydrolysis, reduction in photoluminescence quantum yield. | |

| Radiation (e.g., UV Light) | Not explicitly covered in search results | Ion migration, surface defect formation, non-radiative recombination. | |

| Operational Conditions | Mass Loading | Introduces challenges in SHM techniques [19] | Mechanical stress on PQD films affecting film morphology and charge transport. |

| Dynamic Loads (Vibration) | Can mask damage signatures in structural response [19] | Fatigue of surface passivation layers under continuous electrical bias. | |

| Boundary Conditions | Variations can significantly impact structural response [19] | Interface stability between PQD layer and charge transport layers. |

The effect of these Environmental and Operational Conditions (EOCs) can significantly undermine the reliability and robustness of damage assessment technologies and, by extension, the operational lifetime of the system itself [19]. In PQDs, these factors manifest as surface ligand loss, ion migration, and crystal phase transition, which collectively degrade optoelectronic performance.

Methodologies for Monitoring and Assessment

Advanced monitoring techniques are critical for quantifying degradation without inducing further damage. These methodologies, established in SHM and NDT, provide a blueprint for analyzing PQD stability.

Structural Health Monitoring (SHM) and Non-Destructive Testing (NDT)

SHM and NDT encompass a suite of techniques for identifying structural damage in various systems [19]. SHM can be classified as either passive (measuring operational parameters without direct intervention) or active (using permanent sensors for direct, targeted damage detection) [19]. Advances in sensor technology, including fiber optic sensors, acoustic emission sensors, and Micro-Electro-Mechanical System (MEMS) sensors, have facilitated the deployment of these systems for both large-scale structures and local member assessment [19]. The core challenge is that EOC variations can mask the signature of damage in the structural responses [19].

Experimental Protocols from Analogous Fields

Protocol 1: In-situ Dynamic Vibration Monitoring for Preheater Towers [20]

- Objective: To assess structural degradation caused by severe operational conditions, notably prolonged exposure to high temperatures.

- Methodology:

- In-situ Non-destructive Dynamic Tests: Conduct vibration tests on all structural platforms to capture operational modal parameters (e.g., frequencies, mode shapes).

- Finite Element (FE) Modeling: Create a detailed computational model of the structure.

- Model Calibration: Rigorously calibrate the FE model against the observed vibration data to match frequencies at different levels.

- Parameter Comparison: Compare the obtained mechanical parameters from the calibrated model with known properties of concrete after long-term exposure to elevated temperatures.

- Outcome: Revealed significant degradation due to prolonged thermal exposure, particularly in areas with lost thermal insulation.

Protocol 2: Quantitative Analysis of Experimental Data using Statistical Methods [21]

- Objective: To determine if a measured difference between two experimental results (e.g., concentration of a substance) is statistically significant or due to random chance.

- Methodology:

- Formulate Hypotheses: Establish a Null Hypothesis (H₀: there is no difference between the means) and an Alternative Hypothesis (H₁: there is a difference).

- Perform F-test: Compare the variances of the two data sets to determine if they are equal. This informs the choice of subsequent t-test.

- Perform t-test: Calculate the t-statistic using the formula that considers the difference in means, pooled standard deviation, and sample sizes.

- Decision Making: Compare the absolute value of the t-statistic to the critical t-value from distribution tables at a chosen significance level (α, typically 0.05). If |t-statistic| > t-critical, reject the null hypothesis. Alternatively, if the P-value is less than α, reject the null hypothesis.

- Outcome: Provides a statistically rigorous basis for concluding whether two sets of measurements are meaningfully different, which is vital for quantifying degradation rates.

Visualization of Workflows

Structural Health Monitoring Process

The following diagram illustrates the integrated process of Structural Health Monitoring, from data acquisition to decision-making, highlighting the critical challenge of compensating for Environmental and Operational Conditions (EOCs).

Statistical Validation of Experimental Data

This diagram outlines the statistical workflow for validating whether observed differences in experimental data, such as degradation metrics, are significant.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Key Materials and Tools for Degradation and Stability Research

| Item | Function / Application | Technical Notes |

|---|---|---|

| Fiber Optic Sensors [19] | Used in active and passive SHM for precise strain and temperature measurement. | Immune to electromagnetic interference, suitable for long-distance monitoring. |

| Accelerometers [19] | Measure vibrational responses to assess dynamic properties and detect damage in structures. | Critical for modal analysis in civil structures; analogous to probing phonon modes in materials. |

| Acoustic Emission Sensors [19] | Detect high-frequency waves generated by rapid crack propagation and internal damage. | Used in passive SHM; can identify active degradation events in real-time. |

| Spectrometer [21] | Measures absorbance of solutions to determine concentration; directly applicable to optical characterization of PQDs. | Enables construction of standard curves (e.g., absorbance vs. concentration). |

| Finite Element Software | Numerical tool for modeling structural behavior and converting measured data into meaningful information [19]. | Used for simulating stress distributions, thermal effects, and predicting failure points. |

| FCF Brilliant Blue Dye [21] | Model compound for preparing standard solutions and building absorbance-concentration curves. | Analogous to using standard samples for calibrating instrumentation in PQD research. |

The challenges of structural degradation under operational and ambient conditions represent a critical frontier in the quest for stable PQD electronics. The methodologies refined in civil SHM and NDT—emphasizing in-situ monitoring, robust statistical validation, and computational modeling—provide a powerful translational framework. By adopting these rigorous approaches, researchers can deconvolute the complex effects of temperature, humidity, and electrical bias on PQD surfaces. Integrating these tools to develop predictive models and effective surface passivation protocols is the key to overcoming the primary barrier to the widespread application of perovskite-based technologies.

Advanced Passivation Techniques: Ligand Engineering, Hybrid Coatings, and Biomedical Integration

Perovskite quantum dots (PQDs) have emerged as leading materials for next-generation optoelectronics, boasting exceptional properties such as high absorption coefficients, size-tunable bandgaps, and superior defect tolerance. [22] [23] However, their inherent instability under environmental conditions and numerous surface defects significantly impede practical application. These challenges originate primarily from the dynamic binding of inherent long-chain insulating ligands (e.g., oleic acid (OA) and oleylamine (OAm)) used in synthesis to ensure colloidal stability. These ligands create substantial barriers to charge transport between adjacent PQDs, compromising device performance. [22] [24] Consequently, sophisticated ligand engineering strategies have become indispensable for modifying PQD surface chemistry to enhance electronic coupling, suppress non-radiative recombination, and improve environmental stability without sacrificing dispersibility.

This technical guide examines advanced ligand engineering strategies—short-chain, bifunctional, and conjugated polymer ligands—within the broader research context of surface passivation mechanisms for PQD electronic stability. Effective surface passivation must address both defect mitigation and charge transport enhancement, a dual requirement that has driven the evolution from simple ligand exchange to sophisticated multi-functional designs. We present quantitative performance comparisons, detailed experimental protocols, and essential research tools to provide a comprehensive resource for researchers and scientists developing stable, high-performance PQD-based electronic and optoelectronic devices.

Core Ligand Engineering Strategies and Performance Analysis

Short-Chain Ligand Exchange Strategies

Short-chain ligand exchange represents a fundamental approach to replacing native long-chain insulating ligands with shorter conductive alternatives, thereby enhancing inter-dot electronic coupling. Conventional methods rely on ester antisolvents like methyl acetate (MeOAc) hydrolyzing under ambient humidity to produce acetate ligands that substitute for OA. [24] However, recent research reveals critical limitations: the hydrolysis is thermodynamically unfavorable and kinetically slow, resulting in incomplete ligand exchange and extensive surface vacancy defects that trap charge carriers. [24]

A transformative Alkali-Augmented Antisolvent Hydrolysis (AAAH) strategy overcomes these limitations by creating an alkaline environment that renders ester hydrolysis thermodynamically spontaneous and lowers the reaction activation energy by approximately nine-fold. [24] Using potassium hydroxide (KOH) coupled with methyl benzoate (MeBz) antisolvent enables the substitution of pristine insulating oleate ligands with up to twice the conventional amount of conductive hydrolyzed counterparts. This method yields light-absorbing layers with fewer trap-states, homogeneous orientations, and minimal particle agglomerations, achieving a certified efficiency of 18.3% in solar cells—the highest among reported PQD solar cells at the time of publication. [24]

Sequential ligand exchange provides another sophisticated short-chain approach. One study demonstrated a two-step process where dipropylamine (DPA) first removes long-chain ligands to improve conductivity, followed by benzoic acid (BA) passivation to address the surface defects introduced in the first step. [22] This sequential treatment on FAPbI₃ PQDs enhanced electronic coupling and suppressed non-radiative recombination, enabling flexible solar cells with a power conversion efficiency (PCE) of 12.13% and exceptional mechanical stability (retaining ~90% initial PCE after 100 bending cycles). [22]

Bifunctional and Dual-Ligand Systems

Bifunctional ligands and complementary dual-ligand systems address multi-faceted surface stabilization by targeting different surface sites or providing synergistic functionalities. These strategies recognize that single ligands often insufficiently passivate diverse defect types on PQD surfaces.

The complementary dual-ligand reconstruction strategy employs trimethyloxanium tetrafluoroborate and phenylethyl ammonium iodide (PEAI), forming a complementary system on the PQD surface through hydrogen bonds. [25] This configuration not only stabilizes the surface lattice and maintains good colloidal dispersion but also significantly improves inter-dot electronic coupling in PQD solids. The result is substantially enhanced optoelectronic properties and environmental stability, achieving a record efficiency of 17.61% for inorganic PQD solar cells. [25]

Layer-by-layer (LBL) solid-state ligand exchange using conjugated short-chain ligands like PEAI represents another advanced tactic. Unlike conventional post-treatments that only passivate the top layer, PEAI-LBL treatment after each PQD deposition cycle more thoroughly removes long-chain OAm ligands and passivates underlying trap states. [26] This approach enhances carrier transport, improves defect passivation, and balances electron and hole injection in CsPbI₃ PQD films, enabling bifunctional electroluminescent solar cells with a champion PCE of 14.18% and impressive red electroluminescence. [26]

Conjugated Polymer Ligands

Conjugated polymer ligands represent a paradigm shift in ligand design, offering simultaneous defect passivation, enhanced charge transport, and controlled nanocrystal packing through previously unexplored π-π stacking interactions. [23] Unlike conventional insulating ligands, these polymers maintain strong binding with PQD surfaces while creating superior charge transport pathways.

Studies have demonstrated conjugated polymers functionalized with ethylene glycol (-EG) side chains (Th-BDT and O-BDT) provide robust surface passivation and significantly influence quantum dot assembly. [23] The -EG functional groups, with abundant lone electron pairs, form strong interactions with PQDs, while the conjugated backbone facilitates hole transport. The structural planarity of the polymer backbone promotes preferential PQD packing orientation, enhancing inter-dot coupling and charge transport.

Devices incorporating these conjugated polymer ligands achieve a maximum PCE exceeding 15%, compared to 12.7% for pristine devices, with notable enhancements in short-circuit current density and fill factor. [23] Furthermore, these devices demonstrate exceptional operational stability, retaining over 85% of their initial efficiency after 850 hours, establishing conjugated polymers as a dual-functional strategy for passivation and controlled PQD assembly. [23]

Table 1: Performance Comparison of Ligand Engineering Strategies in PQD Solar Cells

| Strategy Category | Specific Approach | PQD Material | Key Performance Metrics | Stability Performance |

|---|---|---|---|---|

| Short-Chain Ligand | Alkali-Augmented Hydrolysis (AAAH) [24] | FA₀.₄₇Cs₀.₅₃PbI₃ | Certified PCE: 18.3%Steady-state PCE: 17.85%Average PCE (20 devices): 17.68% | Improved storage and operational stability |

| Short-Chain Ligand | Sequential Ligand Exchange (DPA+BA) [22] | FAPbI₃ | Flexible PCE: 12.13% (0.06 cm²)11.13% (0.12 cm²)10.33% (0.49 cm²)9.96% (0.98 cm²) | ~90% initial PCE after 100 bending cycles (7 mm radius) |

| Bifunctional/Dual-Ligand | Complementary Dual-Ligand [25] | CsPbI₃ | PCE: 17.61% (record for inorganic PQDSCs) | Substantially improved environmental stability |

| Bifunctional/Dual-Ligand | PEAI Layer-by-Layer (LBL) [26] | CsPbI₃ | PCE: 14.18%VOC: 1.23 VElectroluminescence: 130 Cd/m² | Excellent moisture stability (30-50% RH, unencapsulated) |

| Conjugated Polymer | Th-BDT/O-BDT Polymers [23] | CsPbI₃ | PCE: >15% (vs. 12.7% control)Enhanced JSC and FF | >85% initial efficiency after 850 hours |

Experimental Protocols for Ligand Engineering

Sequential Short-Chain Ligand Exchange

The sequential ligand exchange protocol for FAPbI₃ PQDs involves a two-step treatment to first remove long-chain ligands and subsequently passivate emerging defects. [22]

Materials Required:

- As-synthesized FAPbI₃ PQDs (with OA/OAm ligands) in n-hexane (25 mg/mL)

- Dipropylamine (DPA), anhydrous

- Benzoic acid (BA), anhydrous

- Solvents: n-hexane, n-octane, methyl acetate (MeOAc), ethyl acetate (EtOAc)

- Centrifuge and vacuum oven

Step-by-Step Procedure:

- Purification: Precipitate the crude PQD solution using methyl acetate (MeOAc) as an antisolvent, then centrifuge at 8000 rpm for 5 minutes. Discard the supernatant.

- First Ligand Exchange (DPA): Re-disperse the PQD precipitate in 2 mL n-hexane. Add 60 μL DPA under stirring and maintain the reaction for 1 minute. Centrifuge the mixture at 8000 rpm for 5 minutes to obtain the DPA-treated PQDs.

- Second Ligand Exchange (BA): Re-disperse the DPA-treated PQDs in 2 mL n-hexane. Add 3 mL BA-saturated n-octane solution and stir for 1 minute. Precipitate the PQDs using ethyl acetate (EtOAc) and centrifuge at 8000 rpm for 5 minutes.

- Film Fabrication: Re-disperse the final product in n-octane at a concentration of 50 mg/mL for layer-by-layer film deposition. For each layer, spin-coat the PQD solution and rinse with MeOAc during spinning to remove residual ligands and promote assembly.

Conjugated Polymer Ligand Implementation

This protocol details the application of conjugated polymers (Th-BDT or O-BDT) as passivating ligands for CsPbI₃ PQDs after initial ligand exchange. [23]

Materials Required:

- CsPbI₃ PQDs prepared via standard hot-injection method

- Conjugated polymers (Th-BDT or O-BDT) synthesized per reported methods [23]

- Solvents: chlorobenzene, hexane, methyl acetate (MeOAc)

- Spin coater and nitrogen glovebox

Step-by-Step Procedure:

- Standard Ligand Exchange: Deposit CsPbI₃ PQD colloidal solutions layer-by-layer to an optimized thickness (≈300 nm) using standard methyl acetate (MeOAc) rinsing for each layer to remove native long-chain ligands.

- Polymer Solution Preparation: Dissolve the conjugated polymer (Th-BDT or O-BDT) in chlorobenzene at a concentration of 5 mg/mL.

- Polymer Passivation: After depositing the final PQD layer, spin-coat the polymer solution directly onto the PQD solid film at 3000 rpm for 30 seconds inside a nitrogen-filled glovebox.

- Annealing: Thermally anneal the completed film at 70°C for 10 minutes to facilitate polymer-PQD interaction and solvent removal.

- Device Completion: Proceed with the deposition of subsequent charge transport layers and electrodes to complete the solar cell device architecture.

Alkali-Augmented Antisolvent Hydrolysis (AAAH)

This advanced protocol enhances the conventional ester antisolvent rinsing process by introducing alkalinity to boost hydrolysis efficiency. [24]

Materials Required:

- FA₀.₄₇Cs₀.₅₃PbI₃ PQDs in colloidal solution

- Methyl benzoate (MeBz) as primary antisolvent

- Potassium hydroxide (KOH) as alkalinity source

- 2-pentanol (2-PeOH) as solvent for cationic salts

Step-by-Step Procedure:

- Alkaline Antisolvent Preparation: Add a controlled amount of KOH to methyl benzoate (MeBz) and stir thoroughly to create the alkaline antisolvent environment. The optimal KOH concentration must be determined empirically to balance efficient ligand exchange with PQD structural integrity.

- Layer-by-Layer Rinsing: For each layer during the layer-by-layer PQD film deposition, use the KOH/MeBz solution instead of neat MeOAc for the rinsing step. Spin-coat the PQD colloidal solution, then immediately rinse with the alkaline antisolvent during spinning.

- A-site Ligand Exchange (Post-treatment): After achieving the desired film thickness, perform a final post-treatment using formamidinium iodide (FAI) or phenethylammonium iodide (PEAI) salts dissolved in 2-pentanol (2-PeOH) to exchange the A-site cations. The concentration of cationic salt typically ranges from 5-10 mg/mL.

- Film Characterization: The treated PQD solid films should exhibit enhanced electronic coupling, fewer trap states, and more homogeneous crystallographic orientations compared to films treated with conventional ester antisolvents.

Schematic Representations of Ligand Binding Mechanisms

Sequential Short-Chain Ligand Exchange Process

Diagram 1: Sequential Ligand Exchange

Conjugated Polymer Ligand Interaction

Diagram 2: Polymer Ligand Mechanism

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Research Reagents for PQD Ligand Engineering

| Reagent Category | Specific Examples | Function & Purpose | Application Notes |

|---|---|---|---|

| Short-Chain Ligands | Benzoic Acid (BA) [22], Dipropylamine (DPA) [22], Methyl Acetate (MeOAc) [24] | Replace long-chain OA ligands; enhance inter-dot coupling and charge transport. | Use in sequential treatments; DPA first removes ligands, BA then passivates defects. [22] |

| Bifunctional/Dual Ligands | Phenethylammonium Iodide (PEAI) [26], Trimethyloxanium Tetrafluoroborate [25] | Provide complementary surface passivation; stabilize lattice via hydrogen bonding. | Enable bifunctional devices (PV + EL); use in layer-by-layer (LBL) processes. [26] |

| Conjugated Polymers | Th-BDT, O-BDT polymers with ethylene glycol side chains [23] | Dual passivation and charge transport; control QD packing via π-π stacking. | Spin-coat as passivation layer after LBL deposition; enhance stability and efficiency. [23] |

| Alkali Additives | Potassium Hydroxide (KOH) [24] | Enhance ester antisolvent hydrolysis; enable spontaneous ligand exchange. | Add to methyl benzoate (MeBz) antisolvent; optimize concentration for integrity. [24] |

| Antisolvents | Methyl Benzoate (MeBz) [24], Ethyl Acetate (EtOAc) [22] [26] | Remove pristine ligands during rinsing; mediate film assembly and densification. | MeBz with KOH for AAAH strategy; EtOAc for standard rinsing procedures. |

| Precursor Salts | Formamidinium Iodide (FAI) [26], Cesium Carbonate (Cs₂CO₃) [27] | A-site cation sources for PQD synthesis and post-treatment cation exchange. | FAI post-treatment exchanges OAm+ ligands; use 2-pentanol as solvent. [24] |

Perovskite quantum dots (PQDs) have emerged as revolutionary materials in the field of optoelectronics due to their exceptional properties, including high absorption coefficients, tunable bandgaps, and cost-effective solution processability [1] [2]. Despite their remarkable potential, the widespread commercialization of PQD-based devices faces a critical bottleneck: environmental instability. This instability primarily originates from structural degradation under external stimuli such as moisture, oxygen, and thermal stress [1]. The fundamental issue lies in the inherent susceptibility of PQD surfaces to defect formation through ion migration and ligand detachment, where weakly bound ligands dissociate to generate vacancy and interstitial defects that accelerate degradation [1]. These defects promote non-radiative recombination, reduce photoluminescence quantum yield, and ultimately compromise device performance and operational lifetime [1] [28].