SPR System Equilibration: A Complete Protocol for Reliable Biomolecular Interaction Data

This article provides a comprehensive guide to Surface Plasmon Resonance (SPR) system equilibration, a critical yet often overlooked step for obtaining reliable, publication-quality binding data.

SPR System Equilibration: A Complete Protocol for Reliable Biomolecular Interaction Data

Abstract

This article provides a comprehensive guide to Surface Plasmon Resonance (SPR) system equilibration, a critical yet often overlooked step for obtaining reliable, publication-quality binding data. Tailored for researchers, scientists, and drug development professionals, it covers the foundational principles of why equilibration is essential, delivers a step-by-step methodological protocol, addresses common troubleshooting scenarios, and validates the approach by comparing outcomes with suboptimal practices. Mastering this protocol minimizes baseline drift, reduces false positives/negatives, and ensures kinetic and affinity measurements are accurate and reproducible, thereby accelerating drug discovery and biophysical characterization.

Why SPR Equilibration is Fundamental for Reliable Data

In Surface Plasmon Resonance (SPR) biosensor technology, system equilibration is a critical preparatory phase that extends far beyond initial instrument startup. It encompasses the processes required to achieve a stable, noise-free baseline signal from both the sensor surface and the fluidic system prior to initiating binding experiments. Proper equilibration is foundational for obtaining reliable, high-quality data on molecular interactions, as it ensures that subsequent signal changes accurately reflect analyte-ligand binding events rather than system artifacts [1]. For researchers and drug development professionals, a robust equilibration protocol is not optional but a prerequisite for generating kinetically and thermodynamically valid binding parameters, which are essential for informed decision-making in lead optimization and screening pipelines [1] [2].

The necessity of thorough equilibration stems from the extreme sensitivity of SPR, which detects minute changes in refractive index at the sensor surface. An inadequately equilibrated system can introduce significant signal drift, obscuring genuine binding events and compromising the accuracy of calculated rate and affinity constants [3]. This document outlines a comprehensive framework for SPR system equilibration, providing detailed protocols to ensure data integrity across diverse experimental applications.

Core Principles and Quantitative Benchmarks

Defining Equilibration Success Criteria

Successful system equilibration is quantitatively defined by the achievement of a stable baseline, typically characterized by a signal drift of less than 5-10 Resonance Units (RU) per minute [3]. For high-sensitivity experiments, a more stringent target of < 2 RU/min is recommended. The baseline should demonstrate minimal high-frequency noise, with a root-mean-square (RMS) noise level typically below 0.3-0.5 RU [1]. Visually, a properly equilibrated baseline appears as a flat, straight line when signal is plotted against time, with no observable downward or upward trends before the injection of any analyte.

Key Parameters and Performance Standards

Table 1: Quantitative Benchmarks for SPR System Equilibration

| Parameter | Acceptance Criterion | Measurement Method | Impact on Data Quality |

|---|---|---|---|

| Signal Drift Rate | < 5-10 RU/min (Standard)< 2 RU/min (High-Sensitivity) | Slope of signal vs. time plot over 3-5 minutes | High drift inflates calculated response, affects ka/kd accuracy |

| Baseline Noise (RMS) | < 0.5 RU | Statistical analysis of signal over 60 seconds | Excessive noise obscures small-molecule binding events and initial binding rates |

| Buffer Blank Injection | Response < 10-15 RU, flat sensogram | Inject running buffer, analyze binding response | Significant response indicates carryover, non-specific binding, or inadequate equilibration |

| Temperature Stability | ±0.05°C | System sensor reading | Temperature fluctuations cause refractive index changes and signal drift |

| Flow Rate Stability | ±1% of set point | System calibration | Flow variations cause binding rate inaccuracies and mass transport effects |

Experimental Protocols for System Equilibration

Comprehensive Pre-Experiment Equilibration Protocol

This protocol details the steps for achieving system equilibration before any experimental run, typically requiring 30-60 minutes to complete.

Materials Required:

- HBS-EP buffer: 0.01 M HEPES, 0.15 M NaCl, 3 mM EDTA, 0.005% v/v surfactant P20, pH 7.4 [3]

- HBS-N buffer: 0.01 M HEPES, 0.15 M NaCl, pH 7.4 [3]

- BIAdesorb Solution I (0.5% SDS) and Solution II (50 mM glycine-NaOH, pH 9.5) [3]

- Sterile, filtered running buffer (same as to be used in experiment, 0.22 µm filter)

- Sensor chip (e.g., CM5, L1, HPA)

Procedure:

- System Priming: Perform a minimum of three consecutive priming steps using sterile, filtered running buffer. For the final prime, use the exact buffer that will serve as the running buffer in the experiment.

- Sensor Chip Conditioning: If using a new sensor chip or switching application types, execute a conditioning procedure. For a CM5 chip, inject two 1-minute pulses of each: 50 mM NaOH, 10 mM HCl, and 0.5% SDS, at a flow rate of 50-100 µL/min [3].

- Initial Baseline Stabilization: Place the instrument in run mode and monitor the baseline signal for all flow cells for 10-15 minutes. The signal should be monitored in real-time using the instrument's software.

- Buffer Blank Injection Test: Program a series of short injections (60-120 seconds) of running buffer over all active flow cells, using the same flow rate and duration as planned for analyte injections. Analyze the resulting sensograms for any significant deviation from baseline.

- Final Baseline Acquisition: After successful buffer blank injection, allow the system to stabilize for an additional 10-20 minutes. Continuously monitor the drift rate until it consistently remains below the predetermined threshold (e.g., 5 RU/min).

Post-Immobilization Equilibration Protocol

Following ligand immobilization, a separate equilibration procedure is required to stabilize the modified surface.

Procedure:

- Post-Coupling Wash: After the final immobilization step (e.g., ethanolamine block), maintain a continuous flow of running buffer for at least 15-30 minutes.

- Multiple Short Injections: Execute 5-10 short injections (30 seconds) of running buffer over the newly derivatized surface. This helps to remove loosely associated ligand and stabilize the surface.

- Stability Assessment: Monitor the baseline after the final running buffer injection. The baseline should return to within 5 RU of the pre-injection level. If a significant shift is observed, continue buffer flow until stability is achieved.

- Ligand Activity Check (Optional but Recommended): For quality control, perform a single injection of a known positive control analyte at a concentration expected to give a moderate response (50-100 RU). This verifies that the immobilized ligand is active and the surface is properly equilibrated.

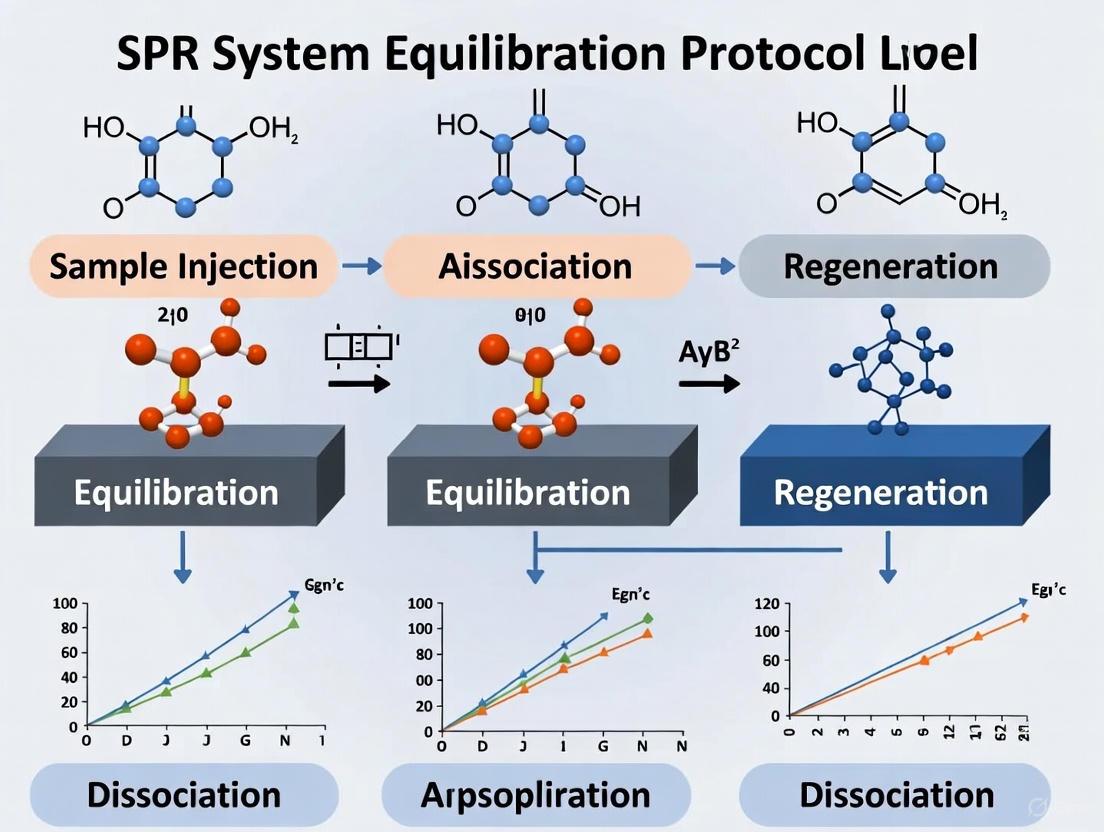

Integrated SPR Equilibration Workflow

The following diagram illustrates the complete decision-making process for SPR system equilibration, integrating both general system and post-immobilization procedures.

Research Reagent Solutions for Equilibration

Table 2: Essential Materials for SPR System Equilibration

| Reagent/Chip Type | Primary Function in Equilibration | Application Notes |

|---|---|---|

| HBS-EP Buffer [3] | Standard running buffer; surfactant P20 minimizes non-specific binding | Use for system priming and baseline stabilization; standard for protein-protein interactions |

| HBS-N Buffer [3] | Running buffer without surfactant | Alternative for lipid-protein studies where surfactants disrupt lipid surfaces [2] |

| CM5 Sensor Chip [3] | General-purpose carboxymethyl dextran surface | Requires conditioning with 50 mM NaOH, 10 mM HCl for equilibration |

| L1 Sensor Chip [2] | Hydrophobic surface for capturing lipid vesicles | Requires specific lipid coating protocols; avoid detergents in buffers |

| BIAdesorb Solution I [3] | 0.5% SDS for system cleaning | Removes residual protein and lipid contaminants during priming |

| BIAdesorb Solution II [3] | 50 mM glycine-NaOH (pH 9.5) for system cleaning | Completes cleaning cycle after Solution I |

| NaOH (10-50 mM) [2] [3] | Surface regeneration and conditioning | Standard for removing residual analyte; concentration varies by application |

| Glycine-HCl (10 mM, pH 1.5-3.0) [3] | Low-pH surface regeneration | Alternative regeneration solution for sensitive protein surfaces |

Troubleshooting Common Equilibration Issues

Problem: Persistent High Baseline Drift

Potential Causes and Solutions:

- Air bubbles in fluidic system: Execute additional prime commands. Degas all buffers thoroughly before use.

- Temperature instability: Verify instrument temperature control is active and setpoint is stable. Allow additional time for thermal equilibration, especially after cartridge insertion.

- Buffer mismatch: Ensure the running buffer used for priming matches the experimental buffer exactly in composition, pH, and salt concentration.

- Contaminated system: Perform an intensive clean with BIAdesorb solutions I and II according to manufacturer protocols [3].

Problem: Excessive Noise in Baseline

Potential Causes and Solutions:

- Particulate contamination: Filter all buffers through 0.22 µm filters immediately before use. Centrifuge protein samples if necessary.

- Flow cell blockage: Inspect sensor chip surface for debris. If present, replace chip and restart equilibration.

- Electrical interference: Ensure proper instrument grounding and separation from high-frequency electrical equipment.

Problem: Significant Response in Buffer Blank Injection

Potential Causes and Solutions:

- Carryover from previous injections: Implement more rigorous wash steps between injections in the method. Increase surfactant concentration in running buffer if compatible with experiment.

- Non-specific binding to surface: Include a non-specific binding reducer such as carboxymethyl dextran or BSA in the running buffer [3]. Consider switching to a different sensor chip type with higher resistance to non-specific binding.

Advanced Considerations for Specific Applications

Equilibration for Lipid-Protein Interaction Studies

When working with lipid surfaces on L1 chips, equilibration protocols require modification. Detergents must be excluded from all buffers as they destabilize lipid surfaces [2]. After lipid vesicle coating, the surface must be stabilized with multiple injections of 0.1 M NaOH, followed by an extended equilibration period with detergent-free buffer (typically 30-60 minutes) [2]. System cleaning must be performed more frequently (every 2-3 days) when running detergent-free buffers to prevent protein accumulation in fluidic lines.

Equilibration for Small Molecule Screening

For fragment-based screening where small binding responses (<10 RU) are expected, enhanced equilibration stringency is necessary. Aim for baseline drift <2 RU/min and RMS noise <0.3 RU. Include additional buffer blank injections during method development to establish a stable response profile. Temperature control is particularly critical, as minor fluctuations disproportionately affect small signals.

By adhering to these comprehensive equilibration protocols, researchers ensure that their SPR systems generate data reflecting true molecular interactions rather than system artifacts, thereby enhancing the reliability of kinetic and affinity constants used in critical drug development decisions.

The Critical Link Between Stable Baselines and Accurate Kinetic Parameters (ka, kd, KD)

Surface Plasmon Resonance (SPR) has emerged as a preeminent technique for label-free, real-time analysis of biomolecular interactions, enabling precise determination of kinetic parameters crucial for drug discovery and development. The accuracy of these parameters—association rate (k~a~), dissociation rate (k~d~), and equilibrium dissociation constant (K~D~)—heavily depends on establishing and maintaining stable baselines throughout SPR experiments. Proper system equilibration represents a fundamental prerequisite for obtaining reliable kinetic data, as it minimizes instrumental drift, ensures consistent refractive index matching, and provides a stable foundation for measuring binding events. Within the context of biomolecular interaction analysis (BIA), the critical importance of stable baselines cannot be overstated, as they directly impact the quality of sensorgrams and the accuracy of derived kinetic constants [4].

The growing appreciation for optimizing drug-binding kinetics has intensified the need for robust SPR methodologies capable of accurately characterizing both high-affinity drug candidates and rapidly dissociating, low-affinity hits encountered early in discovery pipelines [5]. While advanced data analysis approaches, including artificial intelligence and self-organizing maps, show promise for enhancing SPR data interpretation [6], these sophisticated methods remain dependent on high-quality experimental data originating from properly equilibrated systems. This application note establishes comprehensive protocols for SPR system equilibration, detailed methodologies for kinetic parameter determination, and practical strategies for troubleshooting common baseline instability issues, providing researchers with a standardized framework for obtaining pharmacologically relevant kinetic parameters.

Theoretical Foundations

Kinetic Parameters in Biomolecular Interactions

Biomolecular interactions follow principles of mass action kinetics, where the binding event between a ligand (L) and analyte (A) can be represented as:

\boxed{L + A \underset{kd}{\overset{ka}{\rightleftharpoons}} LA}

The association rate constant (k~a~) quantifies how rapidly the complex forms, typically expressed in M⁻¹s⁻¹, while the dissociation rate constant (k~d~) describes how quickly the complex dissociates, measured in s⁻¹. The equilibrium dissociation constant (K~D~), calculated as k~d~/k~a~, represents the analyte concentration at which half the ligand binding sites are occupied at equilibrium [7] [4]. These kinetic parameters provide critical insights into molecular mechanism and therapeutic potential, with prolonged target residence time (slow k~d~) increasingly recognized as a key determinant of drug efficacy and duration of action [5].

The Role of Stable Baselines in Parameter Accuracy

Stable baselines serve as the fundamental reference point from which all binding responses are measured in SPR experiments. Baseline instability introduces systematic errors that propagate through data analysis, ultimately compromising kinetic parameter accuracy. Several critical aspects of SPR data interpretation depend directly on baseline stability:

- Accurate R~max~ Determination: The maximum response theoretically achievable when all ligand binding sites are occupied must be precisely determined for reliable kinetic fitting. Baseline drift distorts R~max~ estimation, leading to erroneous calculations of binding stoichiometry and affinity [7].

- Preise Initial Binding Rates: The early association phase, crucial for determining k~a~, requires a stable starting baseline for correct quantification of initial binding velocities.

- Reliable Dissociation Profiles: Accurate characterization of k~d~ depends on undisturbed dissociation phases, where a stable baseline ensures proper quantification of complex decay without confounding drift artifacts.

- Meaningful Reference Subtraction: Double referencing methodologies, essential for isolating specific binding signals, assume minimal baseline variation between sample and reference flow cells [7].

Table 1: Impact of Baseline Instability on Kinetic Parameters

| Baseline Issue | Effect on k~a~ | Effect on k~d~ | Effect on K~D~ | Mechanism |

|---|---|---|---|---|

| Positive Drift | Overestimation | Underestimation | Underestimation | Artificial increase in response during association and artificial persistence during dissociation |

| Negative Drift | Underestimation | Overestimation | Overestimation | Artificial decrease in response during association and artificial decay during dissociation |

| High-Frequency Noise | Reduced precision | Reduced precision | Reduced precision | Increased uncertainty in curve fitting, particularly during initial association and late dissociation |

| Baseline Steps | Systematic error | Systematic error | Systematic error | Incorrect reference point establishment for binding phases |

Experimental Design and Equilibration Protocols

Pre-Experimental System Preparation

Comprehensive system preparation establishes the foundation for stable baselines and accurate kinetic parameter determination. The following protocol must be rigorously implemented prior to kinetic characterization experiments:

Sensor Chip Functionalization:

- Surface Cleaning: Initialize with consecutive 2-minute injections of 0.1% SDS, 10 mM glycine-HCl (pH 2.0), and 50 mM NaOH at flow rates ≥50 μL/min [8].

- Surface Activation: For amine coupling, inject a 7-minute pulse of EDC/NHS (1:1 mixture, 0.4 M/0.1 M) at 10 μL/min.

- Ligand Immobilization: Dilute ligand to appropriate concentration in suitable immobilization buffer (typically sodium acetate, pH 4.0-5.5) and inject until desired immobilization level achieved. For CD28 studies, immobilization at 50 μg/mL achieved optimal response levels of approximately 1750 RU [8].

- Surface Blocking: Deactivate remaining active esters with 7-minute injection of 1 M ethanolamine-HCl (pH 8.5).

- Surface Washing: Implement three consecutive 1-minute injections of regeneration solution appropriate for the interaction (e.g., 10 mM glycine pH 2.0 for antibodies) to remove non-covalently attached ligand.

Buffer System Equilibration:

- Buffer Matching: Ensure running buffer and sample buffer are identical in composition, including salt concentration, pH, and additive content. Supplement both with equivalent DMSO concentrations (typically ≤2%) when testing small molecules [8].

- Degassing: Thoroughly degas all buffers using vacuum degassing or sonication under vacuum to prevent bubble formation during experiments.

- Temperature Equilibration: Allow all buffers and samples to reach instrument temperature prior to experimentation (minimum 30 minutes at room temperature).

- System Priming: Prime the fluidic system with at least three volumes of running buffer before establishing a baseline.

Table 2: Optimal Immobilization Conditions for Various Ligand Types

| Ligand Type | Recommended Immobilization Level (RU) | Sensor Chip | Coupling Chemistry | Flow Rate (μL/min) |

|---|---|---|---|---|

| Small Molecules (<500 Da) | 50-200 | CM5 | Amine | 10 |

| Antibodies | 5,000-10,000 | CM5 | Amine | 10 |

| Membrane Proteins | 2,000-5,000 | CAP | Capture | 5 |

| Peptides | 500-2,000 | CM5 | Amine | 10 |

| Multiepitope Proteins (e.g., PQ20) | 1,000-3,000 | CM5 | Amine | 10 |

Comprehensive System Equilibration Protocol

Achieving system equilibration requires methodical implementation of the following steps:

Initial Baseline Establishment:

- Flow running buffer at experimental flow rate (typically 30 μL/min) for minimum 60 minutes.

- Monitor baseline stability, requiring <0.5 RU drift over 10-minute period for kinetic experiments.

- If instability persists, extend equilibration time in 30-minute increments until stability criterion met.

Solvent Correction Calibration:

- Prepare running buffer with varying DMSO concentrations (1.5%, 2.0%, 2.5%) when screening small molecule libraries.

- Inject each solvent calibration solution for 60 seconds at 30 μL/min.

- Verify response returns to baseline between injections with <1 RU deviation.

- Generate solvent calibration curve to correct for DMSO refractive index effects [8].

Ligand Surface Conditioning:

- Implement 3-5 regeneration cycles using optimized regeneration solution.

- Monitor baseline stability after each regeneration, requiring <1 RU deviation from initial baseline.

- For CD28 protein surfaces, validate stability with control antibody injections (2 μg/mL) showing <5% variation in binding response across cycles [8].

Reference Surface Normalization:

- Ensure reference surface exhibits minimal non-specific binding (<1% of ligand surface response).

- Validate reference surface performance with analyte injection at highest test concentration.

The following workflow diagram illustrates the critical steps in establishing a properly equilibrated SPR system:

Data Acquisition and Analysis Methodologies

High-Quality Sensorgram Acquisition

Acquiring sensorgrams suitable for robust kinetic analysis requires careful experimental design:

Association Phase Parameters:

- Injection Volume: Utilize sufficient volume to achieve ≥95% saturation for highest analyte concentration.

- Flow Rate: Employ flow rates ≥30 μL/min to minimize mass transport limitations [7] [4].

- Data Collection Frequency: Acquire data at minimum 5 Hz frequency to adequately capture rapid binding events, particularly for low-affinity interactions with k~off~ ≥10 minute⁻¹ [5].

Dissociation Phase Parameters:

- Dissociation Time: Allow sufficient dissociation time (typically ≥10 × 1/k~d~) for reliable dissociation rate determination.

- Baseline Re-establishment: Confirm return to within 1 RU of pre-injection baseline before subsequent analyte injections.

Concentration Series Design:

- Range: Employ analyte concentrations spanning 0.1 × K~D~ to 10 × K~D~ for comprehensive characterization.

- Replication: Include duplicate injections at minimum, with triplicate recommended for low-affinity interactions.

Kinetic Analysis Workflow

The following workflow ensures systematic approach to kinetic parameter determination:

- Reference Subtraction: Subtract reference flow cell responses to eliminate bulk refractive index effects and non-specific binding.

- Double Referencing: Further subtract buffer injection responses from analyte sensorgrams to remove systematic artifacts [7].

- Model Selection: Initiate analysis with simplest 1:1 binding model before progressing to more complex interaction models.

- Global Fitting: Simultaneously fit association and dissociation phases across all analyte concentrations to determine k~a~ and k~d~ [7].

- Parameter Validation: Verify that fitted R~max~ values align with theoretical predictions based on immobilization level and molecular weights.

Table 3: Troubleshooting Guide for Common Kinetic Analysis Issues

| Problem | Potential Causes | Solutions | Impact on Parameters |

|---|---|---|---|

| Poor Curve Fitting | Incorrect model, Mass transport limitation | Test alternative models, Increase flow rate | Inaccurate k~a~ and k~d~ |

| R~max~ Mismatch | Incorrect molecular weight, Partial activity | Verify protein characterization, Calculate theoretical R~max~ | Incorrect stoichiometry and K~D~ |

| High Chi² Values | Noisy data, Model inadequacy | Increase data smoothing, Test complex models | Reduced confidence in all parameters |

| Inconsistent Replicates | Air bubbles, Surface instability | Extend equilibration, Degas buffers | Poor reproducibility |

| Drifting Baselines | Temperature fluctuations, Buffer mismatch | Improve temperature control, Verify buffer matching | Systematic errors in k~d~ |

The relationship between data quality, model selection, and parameter accuracy is illustrated below:

Advanced Applications and Case Studies

High-Throughput Screening of Small Molecule Inhibitors

The SPR-based workflow for identifying CD28-targeted small molecules demonstrates the critical importance of stable baselines in high-throughput screening environments. Key methodological considerations included:

Library Design: A 1056-compound subset from the Enamine Discovery Diversity Set was selected for its enrichment in chemotypes designed to engage GPCR-like and protein-protein interaction interfaces, making it particularly suitable for targeting the challenging CD28 costimulatory receptor [8].

Primary Screening Parameters:

- Format: 384-well plate configuration

- Compound Concentration: 100 μM in assay buffer supplemented with 2% DMSO

- Binding Metrics: Compounds evaluated based on level of occupancy (LO), binding response, and dissociation kinetics

- Hit Identification: 12 primary hits identified (1.14% hit rate) from initial screening

Dose-Response Confirmation: Follow-up dose-response SPR screening confirmed micromolar-range affinities for three compounds, with the top hit (DDS5) selected for comprehensive characterization [8].

Orthogonal Validation: Competitive ELISA confirmed DDS5 functionally inhibited CD28-CD80 interaction, validating the biological relevance of SPR-derived hits [8].

AI-Enhanced Kinetic Analysis for Diagnostic Applications

Integration of artificial intelligence, particularly self-organizing maps (SOMs), represents an advanced approach for extracting maximal information from SPR sensorgrams. The serodiagnosis of canine visceral leishmaniasis (CVL) demonstrates this methodology:

Bioreceptor Design: Employed PQ20, a multiepitope chimeric protein containing 20 B- and T-cell epitopes from Leishmania chagasi immunodominant proteins, providing enhanced sensitivity and specificity compared to crude antigens [6].

Kinetic Mechanism: Analysis suggested two immunodominant epitopes of PQ20 through its reaction with polyclonal antibodies, exhibiting high initial association rates (k~a1~ = 2.4 × 10⁵ L mol⁻¹ s⁻¹; k~d1~ = 5.5 × 10⁻⁴ L mol⁻¹ s⁻¹) [6].

SOM Clustering: Projection of high-dimensional SPR data onto topology-preserving 2D maps enabled efficient classification of infected versus healthy patients, with higher specificity achieved at shorter reaction times (100 s) in accordance with kinetic evaluation [6].

Diagnostic Performance: Integration of multiepitope bioreceptors with AI-driven analysis achieved 5.1 nmol L⁻¹ detection limit and improved sensitivity/specificity compared to univariate analysis, enabling rapid CVL surveillance in less than 15 minutes total analysis time [6].

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Reagent Solutions for SPR Kinetic Studies

| Reagent/Chemical | Supplier Examples | Function in SPR Experiments | Application Notes |

|---|---|---|---|

| Sensor Chip CAP | Cytiva | Reversible capture of biotinylated molecules | Enables chip regeneration and repeated use; ideal for membrane proteins [8] |

| PBS-P+ Buffer | Cytiva (#28995084) | Running buffer with surfactant additives | Minimizes non-specific binding; compatible with ≤2% DMSO [8] |

| Enamine DDS Library | Enamine | Diverse small molecule screening collection | Enriched for GPCR and PPI interface engagement; 1056-compound subset [8] |

| CD28 Extracellular Domain | Multiple | Target ligand for immobilization | Residues Asn19-Pro152; glycosylated, disulfide-linked homodimer [8] |

| Anti-CD28 Antibody | Multiple | Positive control for binding validation | Reported IC~50~ ≈ 50 ng/mL in cell-based assays [8] |

| PQ20 Multiepitope Protein | Custom synthesis | Biorecognition element for infectious disease | Contains 20 B- and T-cell epitopes; engineered for Leishmania detection [6] |

| 3-Mercaptopropionic Acid (MPA) | Sigma-Aldrich | Self-assembled monolayer formation | Creates functionalized gold surfaces for ligand immobilization [6] |

| NHS/EDC Coupling Kit | Sigma-Aldrich | Amine coupling chemistry | Standard method for covalent ligand immobilization on carboxylated surfaces [6] |

Establishing and maintaining stable baselines through comprehensive system equilibration represents a fundamental prerequisite for obtaining accurate kinetic parameters from SPR biosensors. The protocols outlined in this application note provide researchers with a standardized framework for achieving the baseline stability necessary for reliable determination of k~a~, k~d~, and K~D~ values. As drug discovery programs increasingly prioritize kinetic parameter optimization alongside traditional affinity measurements, robust SPR methodologies become increasingly vital for establishing meaningful structure-kinetic relationships. The integration of advanced analysis approaches, including artificial intelligence and multiepitope bioreceptors, further enhances the information content derived from properly executed SPR experiments. By adhering to these equilibration protocols and data analysis methodologies, researchers can ensure the kinetic parameters driving critical drug discovery decisions rest upon the firm foundation of stable, well-characterized SPR systems.

Surface Plasmon Resonance (SPR) is a powerful, label-free technology for the real-time analysis of biomolecular interactions, playing a critical role in drug development, particularly in kinetic characterization and quality control of biologics [9] [10]. The accuracy of these measurements is exceptionally vulnerable to the stability of the instrumental baseline, making proper system equilibration a foundational step in any SPR experiment. Inadequate equilibration manifests primarily as baseline drift—a continuous upward or downward movement of the signal when only running buffer is present—and other signal artifacts that can compromise data integrity [11]. Within the context of advanced research, such as monitoring critical quality attributes of monoclonal antibodies (e.g., glycosylation) or studying subtle oligomeric transitions in proteins, even minor drift can lead to significant errors in the interpretation of interaction kinetics and affinities [12] [9]. This application note, framed within a broader thesis on SPR equilibration protocols, details the consequences of poor equilibration and provides validated methods to achieve a stable system, ensuring the generation of reliable, publication-quality data.

The Critical Role of Equilibration in SPR

Equilibration is the process of flowing running buffer over the sensor surface until the system reaches a state of physical and chemical stability, reflected by a flat, low-noise baseline. Baseline drift is typically a sign of non-optimally equilibrated sensor surfaces [11]. This instability often occurs after docking a new sensor chip, following an immobilization procedure, or after a change in the running buffer. The causes are multifaceted, including the rehydration of the sensor surface, wash-out of chemicals from immobilization, and the adjustment of the immobilized ligand to the flow buffer [11].

The consequences of analyzing data from a drifting system are severe. Kinetic rate constants (ka and kd) and the equilibrium dissociation constant (KD) can be significantly miscalculated. For instance, an upward drift can be mistaken for ongoing binding, leading to an overestimation of the association rate (ka) or response at equilibrium (Req). Conversely, a downward drift during the dissociation phase can be misinterpreted as faster dissociation, inflating the kd value. In quality control applications, such as the analysis of antibody glycosylation using FcγRII receptors, drift can obscure the subtle binding differences used to quantify attributes like core fucosylation and terminal galactosylation, leading to incorrect batch quality assessments [9].

Quantitative Impact of Equilibration on Data Quality

The following table summarizes key parameters affected by inadequate equilibration and the typical stability targets for a well-equilibrated system.

Table 1: Data Quality Parameters and Equilibration Targets

| Parameter | Impact of Inadequate Equilibration | Stability Target for Well-Equilibrated System |

|---|---|---|

| Baseline Drift Rate | High, continuous signal change masks true binding signals [11]. | < 0.5 RU/min over a 10-15 minute period with constant buffer flow [11]. |

| Overall Noise Level | Increased high-frequency noise, reducing data precision and confidence in fitting [11]. | < 1 RU (peak-to-peak) during buffer injections [11]. |

| Steady-State Response (Req) | Drift prevents a true plateau from being reached, leading to incorrect KD calculation from steady-state analysis [13]. | Variation of < 2% during the plateau phase of a saturated injection. |

| Kinetic Constants (ka, kd) | Alters the shape of the sensorgram, leading to systematic errors in derived kinetic parameters [11]. | Fitted parameters should be independent of the duration of the pre-injection baseline. |

Achieving these targets requires a systematic approach to system preparation. The equilibration time can vary dramatically, from minutes to several hours, depending on the sensor chip type, the immobilized ligand, and the history of the system (e.g., after cleaning or buffer change) [11]. In our research, systems requiring analysis of small molecules (< 1 kDa) or using high-capacity chips (e.g., CM7) consistently necessitated longer equilibration times, often exceeding 60 minutes, to achieve the sub-1 RU/min drift rate essential for detecting low-response signals.

Experimental Protocols for Optimal Equilibration

Protocol: System Startup and Initial Equilibration

This protocol is designed to stabilize the SPR instrument and fluidics system prior to any experimental run.

- Buffer Preparation: Prepare at least 2 liters of running buffer fresh on the day of use. Use high-purity, HPLC-grade solvents and reagents to prevent contamination [11] [14]. Filter the buffer through a 0.22 µm membrane filter and degas it thoroughly to prevent air spikes in the sensorgram [11].

- System Priming: Prime the entire fluidic path with the freshly prepared, filtered, and degassed running buffer. If the system was previously stored in a different buffer or sanitizing solution, perform at least three to five priming cycles to ensure complete buffer exchange.

- Initial Baseline Monitoring: Initiate a continuous flow of running buffer at the experimental flow rate (e.g., 30 µL/min). Monitor the baseline response for a minimum of 15-30 minutes.

- Stability Check: If a steady downward or upward drift is observed, continue flowing buffer. The system is considered initially equilibrated when the drift rate falls below 5 RU/min. Proceed to the startup cycles protocol.

Protocol: Incorporating Startup and Blank Cycles

This protocol uses the experimental method itself to finalize the equilibration of the sensor surface and account for system-specific artifacts [11].

- Method Setup: Program the full experimental cycle, including all association, dissociation, and regeneration steps.

- Add Startup Cycles: At the beginning of the method, incorporate at least three "start-up" cycles [11]. These are identical to sample cycles but inject running buffer instead of analyte. Execute any planned regeneration steps in these cycles. The responses from these cycles should be excluded from final data analysis and not used as blanks.

- Add Blank Cycles: Intersperse blank injections (running buffer alone) evenly throughout the experimental run. It is recommended to include one blank cycle for every five to six analyte cycles and to end the experiment with a blank cycle [11].

- Purpose: These cycles "prime" the sensor surface, stabilize the system after the first few regeneration steps, and provide essential data for the double referencing procedure during data analysis.

Workflow: Comprehensive SPR Equilibration

Research Reagent Solutions

The following table lists essential materials and reagents critical for successful SPR equilibration and experimentation.

Table 2: Key Research Reagents for SPR Equilibration and Assay Development

| Reagent/Material | Function & Importance | Specific Example / Note |

|---|---|---|

| HBS-EP+ Buffer | A standard running buffer; provides consistent pH and ionic strength, and surfactant P20 minimizes non-specific binding [9]. | 10 mM HEPES pH 7.4, 150 mM NaCl, 3 mM EDTA, 0.005% v/v P20 [9]. |

| Sensor Chips | The solid support for ligand immobilization. Choice depends on immobilization chemistry (covalent vs. capture). | CM5 (dextran matrix for amine coupling), Series S (high capacity), NTA (for His-tagged capture) [13]. |

| Regeneration Solutions | Removes tightly bound analyte from the ligand to regenerate the surface without damaging it. | 2 M NaCl (mild), 10 mM Glycine pH 2.0 (acidic), 10-100 mM NaOH (harsh). Must be empirically determined [13]. |

| Coupling Reagents | Enables covalent immobilization of ligands to the sensor chip surface. | NHS/EDC chemistry for activating carboxyl groups on CM5 chips [9]. |

| Protein A | An affinity capture ligand used to uniformly orient antibodies via their Fc region for analysis [9]. | Essential for assays quantifying mAbs or characterizing Fc-mediated interactions like glycosylation [9]. |

Troubleshooting Baseline Drift and Artifacts

Despite best efforts, drift can persist. The following flowchart guides the systematic diagnosis and resolution of common equilibration issues.

The most common sources of drift, as identified in our thesis research, are:

- Poor Buffer Hygiene: Using buffer stored for too long, or failing to filter and degas, introduces chemical and particulate contaminants that cause drift [11].

- Insufficient Surface Equilibration: After immobilization, the surface requires time to swell and settle. This process can be slow for dense hydrogels or certain ligands [11].

- Carryover from Regeneration: Incomplete removal of a harsh regeneration solution can create a slow, decaying drift as the running buffer re-equilibrates the surface pH.

Advanced Application: Equilibration for Glycosylation Analysis

In a recent application, our integrated SPR assay for simultaneous quantification and glycosylation characterization of monoclonal antibodies in crude bioreactor samples demanded exceptional baseline stability [9]. The assay involves:

- Capturing mAbs from a crude sample on a Protein A surface.

- Injecting FcγRIIA or FcγRIIB to characterize terminal galactosylation and core fucosylation via kinetic analysis.

Even minor drift after the capture phase could significantly alter the calculated binding response during the receptor injection phase, leading to misclassification of the glycan profile. By implementing the protocols above—particularly extended initial equilibration and the use of multiple, evenly spaced blank cycles—we achieved the required stability. This allowed us to reliably detect differences in receptor binding affinity directly attributable to specific glycosylation patterns, enabling at-line monitoring of this critical quality attribute.

A rigorous and systematic approach to SPR system equilibration is not merely a preliminary step but a critical determinant of data fidelity. The consequences of inadequate equilibration—namely baseline drift and associated signal artifacts—propagate through data analysis, rendering kinetic and affinity constants unreliable. The protocols and troubleshooting guides presented here, validated through our research on advanced biosensor applications, provide a clear framework for researchers to achieve a stable baseline. Adherence to these practices in buffer preparation, system startup, and experimental design, coupled with the powerful data refinement technique of double referencing, is essential for producing robust, reproducible, and high-quality SPR data that can confidently inform drug development decisions.

How a Properly Equilibrated System Enhances Data Reproducibility

Surface Plasmon Resonance (SPR) is a powerful, label-free technique for the real-time analysis of biomolecular interactions, providing critical data on binding kinetics and affinity. The reliability of this data is fundamentally dependent on the stability of the instrumental baseline, which is achieved through comprehensive system equilibration. This application note details a standardized protocol for proper SPR system equilibration, demonstrating how this critical step minimizes experimental drift and variability, thereby enhancing the reproducibility and reliability of binding data essential for drug discovery and basic research.

In SPR technology, the interaction between a mobile analyte and an immobilized ligand is monitored in real-time as a change in the refractive index at a sensor chip surface, measured in Resonance Units (RU) [2] [15]. A properly equilibrated system is one where the instrument's fluidics and detection system have been stabilized to the specific running buffer and temperature conditions of the experiment, resulting in a flat, stable baseline. The absence of proper equilibration leads to baseline drift, a continuous upward or downward trend in the signal when no binding is occurring. This drift can obscure the true binding signal, compromise the accuracy of calculated kinetic constants (ka and kd), and ultimately undermine data reproducibility [16].

For researchers in drug development, where decisions are made based on precise affinity measurements (KD), ensuring the system is fully equilibrated is not optional—it is a prerequisite for generating trustworthy data [17].

The Impact of System Equilibration on Data Quality

A stable baseline is the foundation for accurate SPR data interpretation. The following table summarizes the quantitative benchmarks for a properly equilibrated system and the consequences of neglecting this step.

Table 1: Quantitative Benchmarks for a Properly Equilibrated SPR System

| Parameter | Well-Equilibrated System | Poorly Equilibrated System | Impact on Data |

|---|---|---|---|

| Baseline Drift | < ± 0.3 RU/minute [16] | > ± 0.3 RU/minute | Obscures real binding events; complicates kinetic analysis. |

| Buffer Injection Response | < 5 RU [16] | > 5 RU | Introduces noise and systematic error into sensorgrams. |

| Ligand Surface Stability | Stable response over multiple regeneration cycles [16] | Drifting Rmax and changing binding kinetics | Prevents meaningful comparison between analyte cycles. |

| Reproducibility | High repeatability of sample responses [18] | Low repeatability between identical injections | Undermines confidence in kinetic constants and affinities. |

Detailed Equilibration Protocol

This protocol is designed to stabilize the SPR instrument, sensor chip, and ligand surface prior to quantitative binding analysis.

Pre-Equilibration: System and Surface Preparation

- Instrument Priming: After a system startup or cleaning procedure, prime the instrument's fluidic system (Integrated Fluidic Cartridge - IFC) with the designated running buffer (e.g., HBS-EP or PBS with 0.05% Tween-20) to remove storage solutions and air bubbles [19] [18].

- Ligand Immobilization: Immobilize the ligand onto the sensor chip surface using standard amine-coupling or capture chemistry according to manufacturer protocols [3] [15].

- Buffer Matching: Ensure that the running buffer and all analyte samples are perfectly matched in composition (including buffer salts, pH, ionic strength, detergent, and DMSO concentration) to prevent bulk effects, which cause large refractive index shifts [16] [19].

Core Equilibration and Stabilization Steps

Once the ligand is immobilized, the critical equilibration process begins. The workflow below outlines the key steps to achieve a stable system.

- Surface Equilibration to Flow Buffer: Following immobilization, wash the ligand surface extensively with the flow buffer until the baseline is stable. This removes any residual chemicals from the coupling process [16].

- Baseline Stability Check: With the flow buffer passing over all flow channels, observe the baseline. A properly equilibrated system should exhibit minimal drift (< ± 0.3 RU/min) [16].

- Stabilization via Simulated Experiment Cycles: Subject the ligand surface to a series of 4-5 buffer-only injections and regeneration solution injections. This process "conditions" the surface and the fluidics, stabilizing the ligand and the system's response.

- Stability Assessment: After these cycles, the binding response and the baseline should return to the pre-injection level consistently. If the Rmax (maximum binding capacity) drifts or the baseline fails to stabilize, the surface is not yet stable, and further conditioning or troubleshooting is required [16].

Key Reagent Solutions for Equilibration and Binding Studies

The following materials are essential for successful SPR equilibration and experimentation.

Table 2: Essential Research Reagent Solutions for SPR Equilibration

| Reagent / Material | Function & Role in Equilibration | Example |

|---|---|---|

| Running Buffer | The continuous phase for the experiment; perfect buffer matching is critical to prevent bulk shifts and ensure a stable baseline. | HBS-EP, PBS with 0.05% Tween-20 [3] [19] |

| Regeneration Solution | Removes bound analyte from the immobilized ligand without denaturing it, allowing for surface re-use and testing stability. | 10 mM Glycine, pH 1.5-2.5; 50 mM NaOH [3] [16] |

| Ligand | The molecule immobilized on the sensor chip; its stability through multiple regeneration cycles is key to a long-lived surface. | Affinity-purified protein, peptide [3] |

| System Cleaner | Used for periodic instrument cleaning to prevent protein buildup in the fluidics, a common source of baseline drift and high buffer injections. | BIAdesorb solutions 1 & 2 [3] [19] |

| Non-Specific Binding (NSB) Reducer | Added to the running buffer or sample to reduce nonspecific binding to the sensor chip or ligand, improving data quality. | Surfactant P20, Carboxymethyl dextran, BSA [3] [18] |

A properly equilibrated SPR system is the cornerstone of reproducible biomolecular interaction data. By adhering to the detailed protocol outlined herein—emphasizing buffer matching, thorough surface washing, and systematic stabilization cycles—researchers can achieve the stable baseline necessary to collect high-quality, reliable kinetic and affinity data. Integrating these equilibration practices as a standard operating procedure ensures data integrity across experiments and laboratories, ultimately accelerating research and development in pharmaceuticals and life sciences.

A Step-by-Step SPR System Equilibration and Buffer Matching Protocol

Proper system pre-equilibration is a critical prerequisite for generating robust and reliable Surface Plasmon Resonance (SPR) data. This protocol details the essential preparatory steps—focusing on the sensor chip, running buffer, and fluidic system—to establish a stable baseline and minimize experimental artifacts. Within the broader thesis on SPR equilibration protocols, this document establishes the foundational practices that ensure subsequent kinetic and affinity analyses are performed under optimal conditions, thereby enhancing data quality and reproducibility for researchers and drug development professionals [20] [21].

The Scientist's Toolkit: Essential Research Reagents

The following table lists key materials and reagents required for the pre-equilibration and setup of a typical SPR experiment.

Table 1: Key Reagents for SPR System Pre-Equilibration

| Reagent Name | Function and Key Characteristics |

|---|---|

| Running Buffer | Creates the continuous flow phase; should match analyte storage buffer to minimize refractive index differences [21]. Common examples are HEPES-KCl or PBS [13]. |

| Preconditioning Solutions | Conditions the sensor chip surface to ensure stability and remove preservatives. Examples include 1 M NaCl/10 mM NaOH for amine sensors and 50 mM EDTA for HTC sensors [22]. |

| L1 Sensor Chip | A specialized chip with a lipophilic surface designed for the capture of lipid vesicles or nanodiscs, crucial for membrane-protein interaction studies [21]. |

| CM5 Sensor Chip | A versatile, carboxymethylated dextran chip used for covalent immobilization of ligands via amine-coupling chemistry [13]. |

| Desorb Solutions | For stringent system cleaning. Solution 1 is 0.5% (w/v) SDS, and Solution 2 is 50 mM glycine-NaOH, pH 9.5 [21]. |

| Regeneration Solutions | Removes tightly bound analyte from the immobilized ligand between analysis cycles. Specificity depends on the interaction; 10 mM Glycine (pH 2.0) is a common acidic option [13]. |

| NaOH (50 mM) | Used for basic cleaning cycles and as a component of some preconditioning and desorb procedures [21]. |

| CHAPS Detergent (20 mM) | A zwitterionic detergent used for cleaning and solubilization; must be sterile-filtered [21]. |

Pre-Equilibration Workflow

The pre-equilibration process is a sequential workflow that ensures the instrument, sensor chip, and biochemical environment are optimally prepared. The following diagram outlines the primary stages and their key decision points.

Detailed Experimental Protocols

Sensor Chip Preconditioning

Preconditioning stabilizes the sensor surface, removes immobilization-blocking preservatives, and equilibrates it with the running buffer, which is critical for achieving a low-drift baseline [22].

Table 2: Preconditioning Methods by Sensor Chip Type

| Sensor Chip Type | Preconditioning Protocol | Purpose and Notes |

|---|---|---|

| Amine/ HCA | Multiple cycles of elution buffer (1 M NaCl, 10 mM NaOH) and 100 mM HCl. Solutions are addressed to all spots and then individual spots. | Removes chemical preservatives and stabilizes the dextran matrix. Prevents bubble formation during experiments [22]. |

| BTC | Multiple cycles of elution buffer (1 M NaCl, 10 mM NaOH) and running buffer. | Prepares the surface for specific capture chemistry. Using running buffer helps equilibrate the surface to the final experimental conditions [22]. |

| HTC | Multiple cycles of 50 mM EDTA and running buffer. | EDTA chelates metal ions, preparing the surface for immobilization. Follow with running buffer to re-equilibrate [22]. |

| Pro-AG | Multiple cycles of a regeneration solution (e.g., 10 mM Glycine, pH 1.5) and running buffer. | Conditions the surface by simulating regeneration steps, ensuring ligand stability before the actual experiment begins [22]. |

Methodology:

- Dock the experimental sensor chip after completing system cleaning.

- Prime the system with your degassed, filtered running buffer.

- Initiate the preconditioning method specific to your sensor chip type as outlined in Table 2. The instrument will automatically perform the cycles of solution injections.

- Post-conditioning prime. After the method finishes, perform a final prime with running buffer to ensure the system and surface are fully equilibrated.

- Monitor the baseline. Allow the system to run at a continuous, low flow rate until a stable baseline is achieved, which can take several hours. A stable baseline indicates the surface is fully equilibrated [21].

Running Buffer Preparation and Equilibration

The running buffer serves as the liquid phase for analyte delivery and its composition must be optimized to ensure ligand stability, minimize non-specific binding, and prevent bulk refractive index (RI) shifts [20] [13].

Key Buffer Criteria:

- Composition Matching: The running buffer should ideally be identical to the analyte storage buffer to prevent bulk shift artifacts caused by RI differences [21]. For analytes stored in DMSO, the running buffer must contain the same final concentration of DMSO [13].

- Low Ionic Strength for Pre-concentration: When using carboxyl-based chips (e.g., CM5) and planning amine coupling, a low ionic strength buffer (e.g., 10 mM) is required for the pre-concentration step, as high salt masks the charges necessary for electrostatic attraction of the ligand [23].

- Additives to Minimize Non-Specific Binding (NSB): To address NSB, include additives like BSA (typically 1%) to block hydrophobic surfaces, non-ionic surfactants (e.g., Tween 20), or increased salt concentration (e.g., NaCl) to shield charge-based interactions [20].

Methodology:

- Select an appropriate buffer (e.g., HEPES, PBS, or acetate) based on the required pH and compatibility with your biomolecules [13].

- Filter the buffer using a 0.2 µm filter to remove particulates.

- Degas the buffer thoroughly to prevent air bubble formation during the experiment, which can disrupt the SPR signal and damage the fluidic system.

- Equilibrate the entire system by priming the fluidic system with the prepared running buffer and allowing it to flow over the preconditioned sensor chip until a stable baseline is achieved.

System Priming and Cleaning

Priming replaces all liquids in the fluidic path with the fresh, filtered, and degassed running buffer, which is essential for removing air bubbles and stabilizing the baseline. A cleaning step is recommended if the instrument has been idle or when switching buffer systems [21].

Methodology:

- Dock a maintenance chip. Use a dedicated or blank sensor chip to avoid exposing an expensive experimental chip to harsh cleaning solutions.

- Execute a Desorb procedure. Using the instrument's software, run a desorb protocol with solutions like 0.5% SDS (Solution 1) followed by 50 mM glycine-NaOH, pH 9.5 (Solution 2) [21].

- Execute a Sanitize procedure. Follow the desorb with a sanitize step using a 10% bleach solution to ensure biological contaminants are removed [21].

- Prime with running buffer. After cleaning, flush the system extensively with your degassed experimental running buffer to remove all traces of cleaning solutions.

- Dock the experimental chip. Once the system is clean and primed, dock your preconditioned experimental sensor chip and perform a final prime to establish equilibrium.

In Surface Plasmon Resonance (SPR) research, obtaining a stable baseline is not merely a preliminary step but a fundamental prerequisite for generating reliable, publication-quality binding data. The equilibration state of the SPR system directly dictates the signal-to-noise ratio and determines the accuracy of subsequent kinetic and affinity calculations (Stebians et al., 2019) [13]. Baseline instability, manifesting as drift, is frequently an indicator of a system that has not reached complete thermodynamic and chemical equilibrium with its environment. This protocol addresses this critical challenge by establishing a standardized, evidence-based procedure for achieving system stability through controlled overnight buffer flow, thereby providing a solid experimental foundation for all subsequent interactions analyses.

Theoretical Foundation: Understanding Baseline Drift

Primary Causes of Instability

Baseline drift in SPR systems is a phenomenon primarily driven by the gradual equilibration of the sensor surface and the fluidic path with the running buffer. This process is influenced by several physical and chemical factors:

- Surface Rehydration and Conditioning: Newly docked sensor chips or recently immobilized surfaces require extensive hydration to swell the dextran matrix (in the case of CM5 chips) and leach out preservatives or residual chemicals from the immobilization procedure. This rehydration process can cause significant refractive index changes at the sensor surface, observed as baseline drift [11].

- Temperature and Buffer Equilibration: A discrepancy between the temperature of the stored buffer, the instrument, and the laboratory environment creates thermal gradients. As these gradients dissipate, they induce minute but detectable changes in the refractive index of the buffer flowing through the system. Furthermore, buffers stored at 4°C contain higher levels of dissolved air, which can form microbubbles as the buffer warms, creating spikes and instability [11].

- Chemical Equilibration: The sensor surface ligand, particularly proteins, undergoes a period of adjustment to the pH, ionic strength, and chemical composition of the running buffer. This adjustment can involve subtle conformational changes or the release of loosely bound molecules, both of which contribute to drift until a steady state is achieved.

Impact on Data Quality

A drifting baseline directly compromises data integrity by introducing uncertainty in the response unit (RU) measurements. For kinetic analysis, where precise determination of association and dissociation rates is critical, an unstable baseline can lead to significant errors in the calculation of rate constants (ka and kd) and the equilibrium dissociation constant (KD) [13]. In severe cases, low-level binding events may become indistinguishable from background noise, rendering the data unusable.

Core Protocol: Overnight Equilibration

Principle and Rationale

The strategic implementation of overnight buffer flow leverages extended time to complete the slow physicochemical equilibration processes that are impractical to accomplish during a typical working day. This procedure ensures that the sensor surface, the running buffer, and the instrument fluidics are in a state of maximal stability before the introduction of precious analyte samples.

Materials and Reagents

Table 1: Essential Research Reagent Solutions

| Item | Specification/Function |

|---|---|

| Running Buffer | Must be matched to the biological system; e.g., HEPES, Tris, or PBS buffers. Must be 0.22 µm filtered and degassed immediately before use [13] [11]. |

| Organic Solvents | For system cleaning and preparation; e.g., Isopropanol [24]. |

| Detergent Solution | A mild solution (e.g., with a drop of detergent in hot water) for cleaning detector flow cells, if contamination is suspected [24]. |

Step-by-Step Procedure

Buffer Preparation (Day 1, Evening):

- Prepare a fresh batch of running buffer (e.g., 2 liters is recommended for extended use). The buffer composition should reflect the natural conditions of the biomolecular interaction under study, including the correct pH and necessary ions or co-factors (e.g., Mg²⁺ and ATP for proteins like Sec18/NSF) [13].

- Filter the buffer through a 0.22 µm filter to remove particulate matter.

- Degas the buffer thoroughly for at least 30-45 minutes to prevent the formation of air bubbles during the extended run, which create spikes in the sensorgram [11].

System Priming and Chip Docking:

- Prime the SPR instrument with the freshly prepared and degassed running buffer at least three times to ensure the fluidic path is entirely purged of previous solutions and is saturated with the new buffer.

- Dock the sensor chip (either a new chip or one with already immobilized ligand) following the manufacturer's guidelines.

Initiating Overnight Equilibration:

- In the instrument software, set a simple method that continuously flows the running buffer over the sensor surface.

- The flow rate should be set to the standard rate intended for the actual analyte binding experiments (commonly 10-50 µL/min).

- Initiate the method and allow the buffer to flow continuously overnight. A typical duration is 12-16 hours.

Stability Verification (Day 2, Morning):

- Upon returning, visually inspect the real-time sensorgram. The baseline should appear as a flat, stable line. The acceptable drift rate is typically less than 5 RU over a 5-10 minute period.

- To quantitatively assess stability, perform several dummy injections of running buffer (using the same injection parameters planned for the experiment). A stable system will show minimal deviation from the baseline during these blank injections [11].

The following workflow summarizes the key steps of the overnight equilibration protocol:

Complementary Best Practices for Baseline Stability

System Preparation and Start-Up Cycles

Before commencing the overnight run or the main experiment, incorporate several system conditioning steps:

- Start-Up Cycles: Program at least three start-up cycles at the beginning of your experimental method. These are cycles identical to your analyte injection cycles but inject only running buffer. Perform any regeneration steps as well. These cycles "prime" the surface, exposing it to the minor perturbations of injection and regeneration, leading to a more robustly stabilized surface for actual data collection. These cycles should be excluded from final data analysis [11].

- Blank Injections: Throughout the experimental run, intersperse blank injections (buffer alone) evenly among the analyte injections. These blanks are crucial for the data processing technique of double referencing, which helps compensate for residual bulk refractive index effects, drift, and differences between flow channels [11].

Advanced Troubleshooting for Persistent Drift

Table 2: Troubleshooting Guide for Baseline Instability

| Observed Problem | Potential Root Cause | Recommended Solution |

|---|---|---|

| Significant drift after overnight flow | Sensor surface or fluidics not fully equilibrated; Contaminated flow cell. | Extend equilibration time. Flush system with a cleaning solution (e.g., 50:50 isopropanol/water or, if severe, 30% v/v phosphoric acid followed by extensive water wash) [24]. |

| Regular, periodic oscillations in baseline | Pump pulsation; Cycling of a peripheral device (e.g., degasser, air conditioner). | Check pump and pulse damper. Insulate tubing from column outlet to detector. Bypass degasser temporarily to check if it is the source [24]. |

| Sudden spikes or jumps | Air bubbles in the detector flow cell or buffer; Particulate matter. | Ensure thorough degassing of all buffers. Flush system with a wetting solvent like isopropanol. Re-filter buffers [11] [24]. |

| High general noise level | Old or failing UV lamp; Contaminated flow cell; Electronic interference. | Check lamp usage hours. Clean the flow cell. Ensure proper grounding of the instrument [24]. |

Data Processing: Mitigating Residual Instability

Even with meticulous preparation, some experiments may exhibit minor residual drift. In such cases, data processing techniques are essential for refining the data.

- Double Referencing: This is the standard and highly effective method for compensating for bulk effects and minor drift. It involves two steps:

- Subtract the signal from a reference flow cell (with no ligand or an irrelevant ligand) from the signal of the active flow cell. This removes the majority of the bulk refractive index shift and system-related drift.

- Further subtract the average response from multiple blank injections (buffer alone) from the analyte injections. This step corrects for any remaining differences between the reference and active surfaces [11].

- Advanced Processing: For challenging systems, such as Electrochemical SPR (EC-SPR) where the SPR curve shape itself changes, more advanced data processing methods like Karhunen-Loeve (KL) conversion can be employed. This technique processes the entire SPR curve rather than just tracking the minimum angle, efficiently aggregating feature displacements dispersed across multiple angles to maximize data extraction [25].

The "overnight buffer flow" protocol is not an admission of methodological inefficiency but a strategic investment in data quality and reproducibility. By systematically addressing the root causes of baseline drift—surface rehydration, thermal disequilibrium, and chemical adjustment—this procedure establishes a stable foundation essential for accurate determination of binding affinities and kinetics. When combined with robust system preparation, strategic start-up cycles, and diligent data processing via double referencing, researchers can achieve the level of experimental rigor required for reliable and conclusive SPR analysis in drug development and basic research.

The Role of Multiple Buffer Injections and Surface Pre-Conditioning

Surface Plasmon Resonance (SPR) is a powerful, label-free technology for the real-time analysis of biomolecular interactions, playing a critical role in drug discovery, biochemistry, and diagnostic development [15] [26]. The quality and reproducibility of SPR data are fundamentally dependent on the proper preparation and equilibration of the sensor chip surface. Inadequate surface conditioning can lead to high baseline drift, poor immobilization efficiency, and non-specific binding, ultimately compromising kinetic and affinity measurements.

This application note details rigorous protocols for surface pre-conditioning and pre-concentration, procedures designed to ensure the sensor surface is stable, reproducible, and optimally prepared for ligand immobilization and subsequent analyte binding studies. These steps are essential for researchers aiming to generate high-quality, publication-grade data, particularly when working with challenging samples such as small molecules or membrane proteins [27] [28].

Key Concepts and Definitions

Surface Pre-Conditioning

Surface pre-conditioning involves a series of multiple buffer injections over a newly docked sensor chip to stabilize the surface matrix and eliminate air bubbles. This process equilibrates the sensor surface, preventing experimental artifacts and ensuring a stable baseline, which is crucial for accurate kinetic analysis [22].

Pre-Concentration

Pre-concentration is a strategic step used with carboxyl-group-based sensor chips (e.g., CM5, CM4) to enhance the efficiency of ligand immobilization. It involves diluting the protein in a low-ionic-strength buffer at a pH slightly below its isoelectric point (pI). This creates a positive charge on the protein, which is electrostatically attracted to the negatively charged dextran matrix, resulting in a high local concentration of the ligand at the sensor surface prior to covalent coupling [23] [22].

Table 1: Comparison of Key Pre-Treatment Concepts in SPR

| Concept | Primary Goal | Key Mechanism | Applicable Sensor Chips |

|---|---|---|---|

| Pre-Conditioning | Stabilize baseline & surface | Multiple buffer injections to equilibrate matrix | All types |

| Pre-Concentration | Enhance immobilization efficiency | Electrostatic attraction between ligand and surface | Carboxyl-group based (e.g., CM5, CM4, CM3) |

Experimental Protocols

Protocol for Sensor Surface Pre-Conditioning

Pre-conditioning methods are specific to the sensor chip chemistry. The following steps are adapted from manufacturer recommendations [22].

- Dock a new sensor chip in the instrument according to the manufacturer's instructions.

- Select the appropriate pre-conditioning method from the instrument software based on your sensor chip type.

- Run the method, which typically involves repetitive injections of specific solutions over all flow cells. The solutions and cycles vary by sensor chip type.

Table 2: Recommended Pre-Conditioning Methods by Sensor Chip Type

| Sensor Chip Type | Surface Chemistry | Recommended Pre-Conditioning Solutions | Notes |

|---|---|---|---|

| Amine / HCA | Carboxylated | Cycles of 1 M NaCl, 10 mM NaOH and 100 mM HCl | Prepares surface for amine coupling |

| BTC | - | Cycles of 1 M NaCl, 10 mM NaOH and running buffer | - |

| HTC | - | Cycles of 50 mM EDTA and running buffer | - |

| Pro-AG | - | Cycles of regeneration solution (e.g., 10 mM Glycine, pH 1.5) and running buffer | Conditions surface for capture-based assays |

Protocol for Pre-Concentration Optimization

This protocol is used to determine the optimal pH for immobilizing a protein ligand onto a carboxylated sensor chip [23] [22].

- Determine the pI of your target protein using theoretical calculation software or literature.

- Prepare a range of low-ionic-strength buffers (e.g., 10 mM acetate, formate) differing by 0.5 pH units, spanning from pH 3.0 to one unit below the protein's pI. A general rule is:

- pI 3.5–5.5: Use buffers 0.5 pH units below pI.

- pI 5.5–7.0: Use buffers 1.0 pH unit below pI.

- pI >7.0: Use pH 6.0 or lower [23].

- Dilute the ligand to a concentration of 5-25 µg/mL in each of the different pH buffers.

- Inject each sample over the non-activated sensor chip surface using the instrument's "pre-concentration" or "scouting" function.

- Monitor the response: A large, positive spike in the signal indicates successful electrostatic pre-concentration.

- Select the optimal buffer: Choose the buffer that provides a strong pre-concentration signal at the highest possible pH to maintain protein stability and activity. Avoid pH values below 3.0 as they can damage the dextran matrix [23].

Workflow for SPR System Equilibration

The following diagram illustrates the logical workflow integrating both pre-conditioning and pre-concentration into a complete SPR immobilization protocol.

The Scientist's Toolkit: Essential Reagents and Materials

Successful pre-conditioning and immobilization require carefully prepared reagents. The following table lists key solutions and their functions [23].

Table 3: Essential Research Reagent Solutions for SPR Pre-Treatment

| Reagent / Solution | Composition / Preparation Example | Primary Function in Protocol |

|---|---|---|

| Running Buffer | 10 mM HEPES, 150 mM NaCl, 3.4 mM EDTA, 0.005% surfactant P20, pH 7.4 [23] | Continuous flow buffer for baseline stabilization and sample injection. |

| Acetate Buffer (0.5 M) | Dissolve 2.05 g sodium acetate (Mr 82.03) in 50 mL H₂O; use 10 mM for dilutions [23] | Low-ionic-strength buffer for pre-concentration scouting and ligand dilution. |

| Formate Buffer (0.5 M) | Dissolve 1.7 g sodium formate (Mr 68.01) in 50 mL H₂O; use 10 mM for dilutions [23] | Alternative low-ionic-strength buffer for pre-concentration. |

| EDC Solution (0.4 M) | Dissolve 750 mg EDC (Mr 191.7) in 10.0 mL H₂O. Aliquot and store at -20°C. [23] | Activates carboxyl groups on the sensor surface for covalent coupling. |

| NHS Solution (0.1 M) | Dissolve 115 mg NHS (Mr 115.09) in 10.0 mL H₂O. Aliquot and store at -20°C. [23] | Stabilizes the activated ester intermediate, improving immobilization efficiency. |

| Ethanolamine (1 M, pH 8.5) | Dissolve 611 mg ethanolamine-HCl in 10.0 mL H₂O and adjust pH to 8.5. Aliquot and store at -20°C. [23] | Blocks remaining activated ester groups after immobilization. |

| Regeneration Scouting Solutions | Acids (e.g., 10-100 mM Glycine-HCl, pH 1.5-3.0), alkalis (e.g., 10 mM NaOH), high salt, detergents (e.g., 0.01-0.5% SDS) [29] | Used to identify conditions that fully remove analyte while preserving ligand activity. |

Troubleshooting and Quality Control

Even with optimized protocols, challenges can arise. The following points address common issues and quality control measures.

- Low Pre-Concentration Signal: Confirm the buffer pH is below the protein's pI and that the ionic strength is low (e.g., 10 mM). Use a more concentrated ligand stock solution to avoid altering the coupling buffer's pH and salt concentration [23].

- High Baseline Drift After Pre-Conditioning: Ensure the system has been thoroughly primed with running buffer and that all solutions are degassed. Repeat the pre-conditioning cycle if necessary [22].

- Assessing Surface Quality: For advanced applications, particularly with L1 chips used for lipid membranes, the shape of the SPR reflectivity curve itself can be analyzed quantitatively to monitor surface degradation over multiple regeneration cycles [27].

- Regeneration Optimization: The ideal regeneration buffer completely removes bound analyte without damaging the immobilized ligand. Start with mild conditions and progressively increase intensity. Monitor the baseline and binding response after regeneration; a stable baseline and consistent analyte binding indicate successful regeneration [29].

Within the broader context of Surface Plasmon Resonance (SPR) system equilibration protocols, the precise matching of running and sample buffer compositions represents a foundational prerequisite for acquiring high-quality, kinetic data. Bulk shifts, also referred to as solvent effects, are signal artifacts caused by differences in the refractive index (RI) between the analyte sample and the running buffer [20]. These artifacts manifest as characteristic square-shaped jumps in the sensorgram at the very beginning and end of analyte injection, potentially obscuring genuine binding events, particularly for interactions with fast kinetics or small molecules [30] [20]. This application note details the critical procedures for buffer matching, providing a standardized protocol to eliminate these distortions and ensure data integrity in drug discovery and basic research.

Understanding the Bulk Shift Phenomenon

A bulk shift occurs when the composition of the injected analyte sample is not perfectly matched to the running buffer flowing through the SPR instrument. Since SPR is a mass-sensitive optical technique that measures changes in refractive index, any difference in buffer composition is detected as a change in signal [13]. This effect is distinct from and independent of the specific binding between the analyte and the immobilized ligand.

The resultant sensorgram shows an immediate, sharp increase in Response Units (RU) at the injection start, a sustained plateau during injection, and an immediate, sharp decrease at the injection end [20]. While this artifact can sometimes be partially compensated for by reference surface subtraction, the correction is often imperfect. Furthermore, for systems with rapid binding kinetics, it becomes nearly impossible to distinguish the true binding signal from the bulk effect [20]. Therefore, proactive matching of buffer compositions is the most reliable and recommended solution.

Essential Reagents and Materials

Table 1: Key Research Reagent Solutions for SPR Buffer Matching

| Reagent/Solution | Function & Importance in Buffer Matching |

|---|---|

| Running Buffer [31] | The continuous phase carrying the analyte. Common formulations include HBS-PE, TBS-P, or PBS-P, often supplemented with detergents (e.g., 0.01% P20). It establishes the baseline refractive index. |

| Dialysis System [30] | A primary method for exchanging the analyte into the running buffer, ensuring perfect compositional matching and eliminating bulk shifts. |

| Size Exclusion Columns [30] | An alternative, rapid method for buffer exchange of small analyte volumes into the running buffer. |

| Bovine Serum Albumin (BSA) [31] | An additive (e.g., 0.1%) to running buffer to minimize non-specific adsorption of analyte to vials and instrument tubing. |

| Detergents (e.g., Tween 20, P20) [20] [31] | Non-ionic surfactants added to the running buffer to suppress hydrophobic non-specific binding. Concentrations may be adjusted up to 0.1%. |

| High-Salt Solutions (e.g., NaCl) [20] [31] | Used to increase ionic strength (e.g., up to 250 mM) in the running buffer to suppress charge-based non-specific interactions. |

Core Protocol for Buffer Matching and Equilibration

This protocol outlines the steps for preparing matched running and sample buffers to prevent bulk shifts.

Preparation of Running Buffer

- Formulate Buffer: Prepare the running buffer according to your experimental needs. Standard buffers like HBS-PE (10 mM HEPES pH 7.4, 150 mM NaCl, 3.4 mM EDTA, 0.01% P20) are a common starting point [31].

- Fresh Preparation: Ideally, prepare buffers fresh daily to prevent microbial growth or chemical degradation. Avoid topping off old buffer with new buffer [30].

- Filtration and Degassing: Filter the buffer through a 0.22 µm filter to remove particulates. Subsequently, degas the buffer thoroughly to prevent the formation of micro-bubbles in the fluidics, which can cause spikes and drift [30] [31]. Note that buffers stored at 4°C will contain more dissolved gas and require degassing after warming.

- Additives: At this stage, add any necessary stabilizing agents or detergents like BSA or Tween 20 to the running buffer [31].

Matching the Analyte Sample Buffer

- Dialysis: This is the gold-standard method. Reconstitute or dialyze the analyte directly against the final, degassed running buffer. Use the buffer from the final dialysis exchange as the sample dilution buffer [30].

- Buffer Exchange: For smaller volumes, use size exclusion columns (e.g., desalting columns) to rapidly exchange the analyte into the running buffer [30].

- Handling Volatile Components: For analytes requiring organic solvents like DMSO:

- Dialyze the analyte against running buffer containing the precise required DMSO concentration.

- Use the dialysis buffer as the running buffer and for any further dilutions [30].

- Always cap sample vials to prevent evaporation, which concentrates the analyte and changes the solvent composition, leading to bulk shifts [30].

System Equilibration and Testing

- Inject Buffer Blanks: After system startup and priming, perform several injections of running buffer over both active and reference surfaces. The sensorgram should be flat with no observable drift or jumps [30].

- Calibration Injection Series: To test system performance and buffer matching, create a calibration series. Prepare a dilution series of a solution with a known RI difference, such as running buffer with 50 mM extra NaCl, in a serial dilution (e.g., 50, 25, 12.5, 6.3, 3.1, 1.6, 0.8, 0 mM) [30].

- Perform Test Run: Inject the series from low to high concentration over a plain gold or dextran chip. Monitor the sensorgrams for smooth transitions and a steady state. The final running buffer injection confirms no carry-over [30].

Quantitative Assessment of Bulk Effects